Roof structure of sandblasting room

A technology of sandblasting and driving mechanism, applied in the direction of roof, building components, building structure, etc., can solve the problems of large span, complicated design and installation, and heavy load of flexible gates, achieve simple and direct transmission route, improve hoisting efficiency, improve The effect of blasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

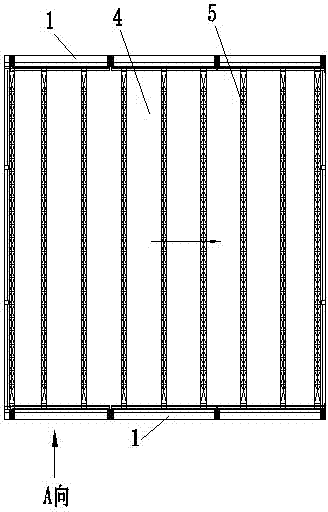

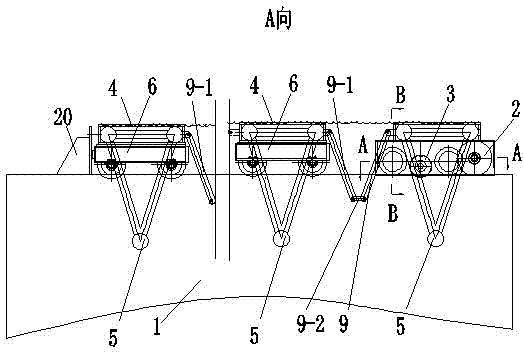

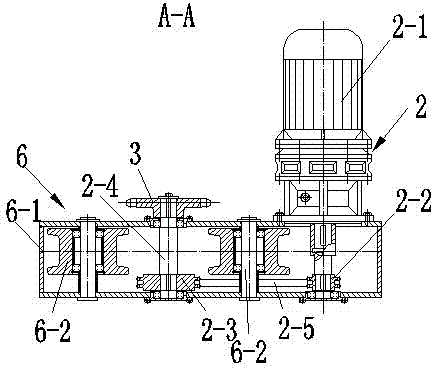

[0019] like Figure 1~6 As shown, a roof structure of a sandblasting room includes a wall 1, a driving mechanism 2, a transmission sprocket 3, a flexible tarpaulin 4, several trusses 5, several trolleys 6, sliding rails 7, chains Type track 8 and hinge mechanism 9, sliding track 7 and chain track 8 are fixedly connected on the top of wall body 1, drive mechanism 2 and drive sprocket wheel 3 transmission connections, and all are fixedly connected on the first trolley 6, finally A trolley 6 is provided with a limit fixing plate 20, and the transmission sprocket 3 is engaged with the chain track 8 for transmission. Through the transmission connection of the hinge mechanism 9, the trolley 6 is connected with the sliding track 7 in a rolling manner, and the flexible tarpaulin 4 is fixedly connected with several trusses 5 .

[0020] see image 3 As shown, in ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com