An anti-siphon structure of water inlet valve

An anti-siphon and water inlet valve technology, which is used in flushing equipment with water tanks, water supply devices, buildings, etc., can solve problems such as large errors in water inlet valves, CL line labeling errors, and polluted water sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

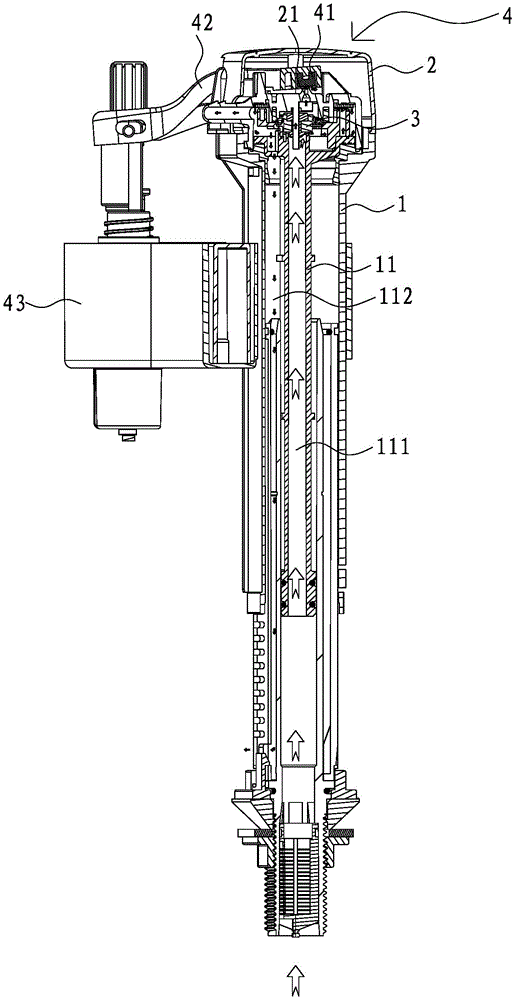

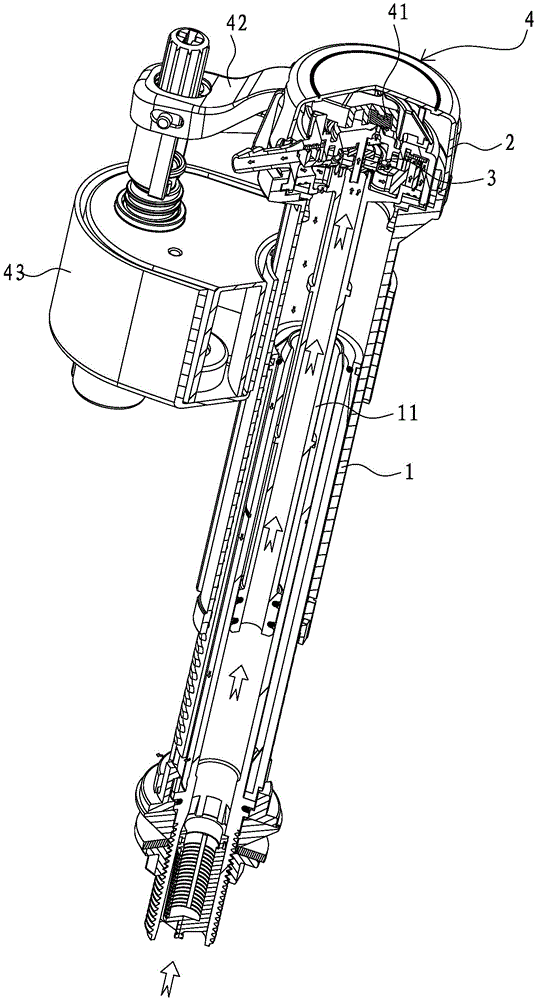

[0047] refer to Figure 1 to Figure 8 As shown, the first embodiment of an anti-siphon structure of a water inlet valve disclosed by the present invention includes a water inlet pipe body 1 , an inner core pipe 11 , a sealing seat 2 , a gasket 3 and a water stop mechanism 4 .

[0048] In this embodiment, the water stop mechanism 4 is composed of a seal seat 2, a seal pad 3, a back pressure pad 41, a swing arm 42 and a buoy 43, that is, the seal pad 3 also functions as a water stop pad, and the seal seat 2 also functions as a water stop pad. The function of the top cover makes the overall structure simpler.

[0049] An air inlet hole (not shown in the figure) is opened on the sealing seat 2, and the sealing seat 2 and the sealing gasket 3 are arranged in cooperation. The sealing seat 2 is installed on the upper end of the water inlet pipe bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com