Box-packaging mechanical arm and box-packaging device

A technology of manipulators and boxes, applied in the field of packaging, can solve the problems of low efficiency and unfavorable mass production of manual methods, and achieve the effect of simple structure, fast movement and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to solve the problem of unreliable packing method, a packing manipulator and packing device are proposed to realize fast and reliable packing.

[0037] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

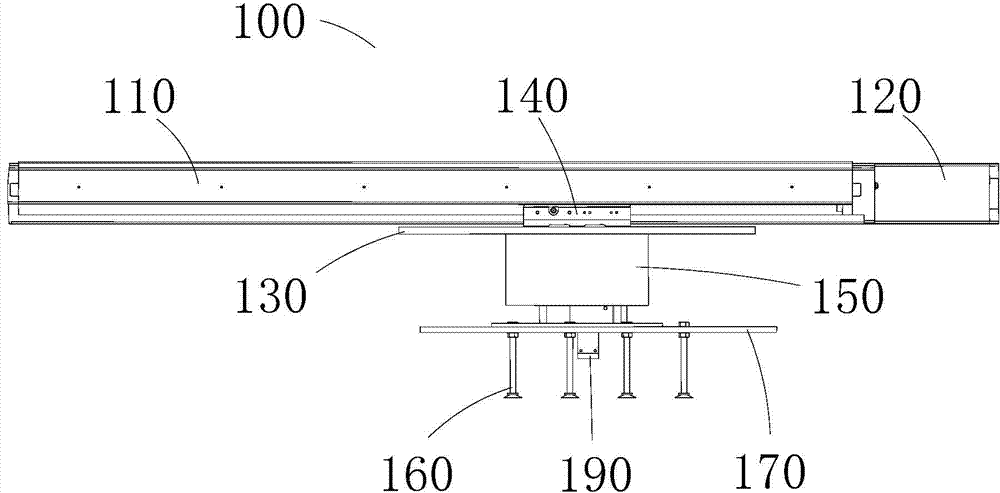

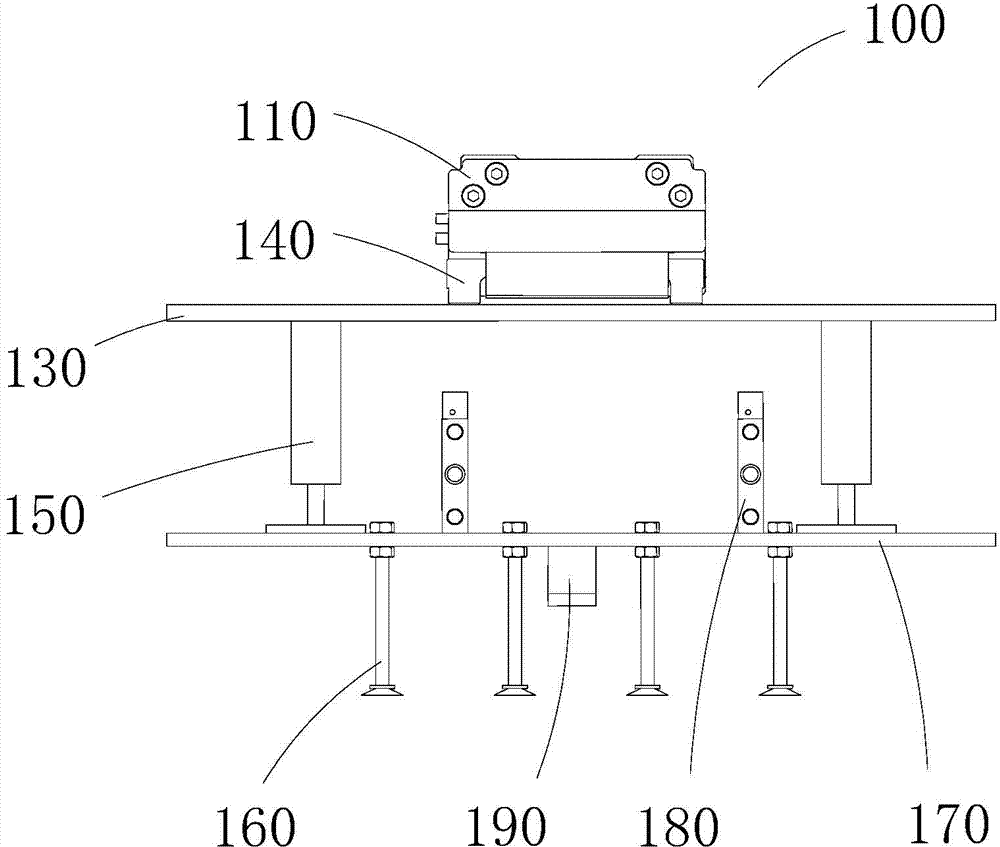

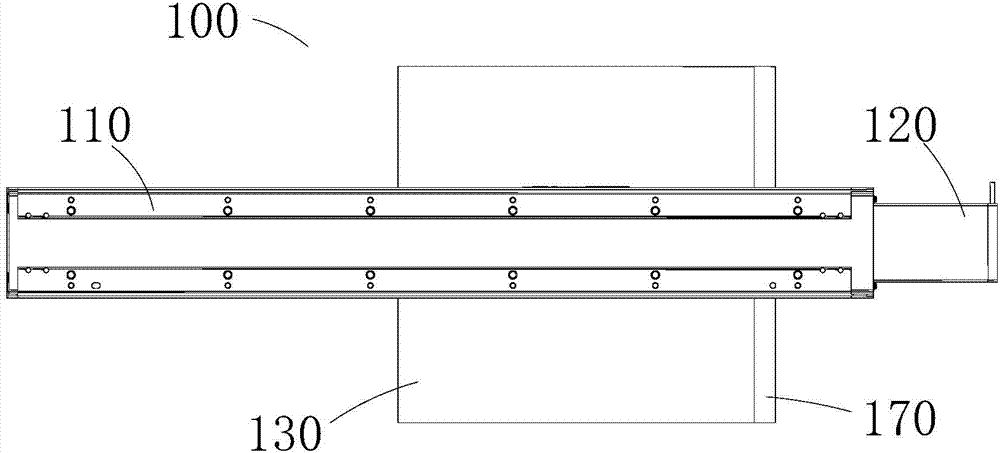

[0038] see figure 1 As shown, it is a schematic front view of the packing manipulator of the present invention. A packing manipulator 100 of the present invention includes a slide rail 110, a connecting slider 140, a telescoping mechanism and a picking mechanism.

[0039] The connecting slider 140 moves along the sliding rail 110 . In this embodiment, the moving track of the sliding rail 110 is a straight line, and the connecting slider 140 moves left and right along the sliding rail 110 .

[0040] The telescopic mechanism is connected with the connecting slider 140, and the connecting slider 140 drives the telescopic mechanism to move along the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com