Wheel assembly for load-carrying vehicle

A wheel and assembly technology, applied in vehicle parts, tire parts, tire edges, etc., can solve the problems of shortened service life, high manufacturing cost, wear and other problems, achieve good load capacity, ensure stability and consistency, improve The effect of security and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The wheel assembly for a truck of the present invention will be described in detail below in conjunction with the accompanying drawings.

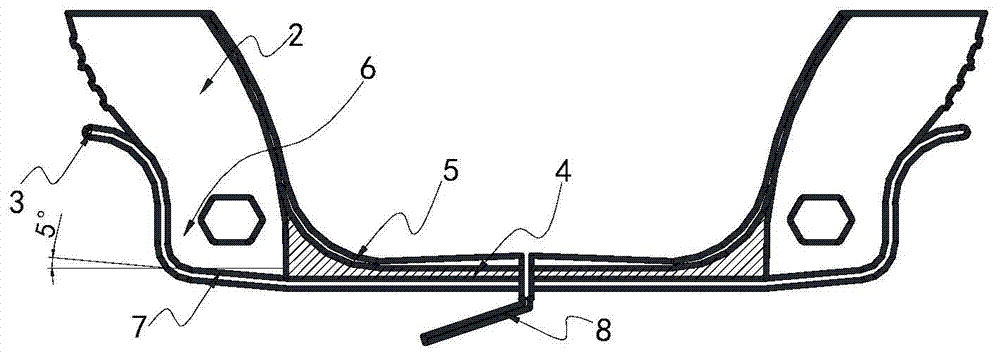

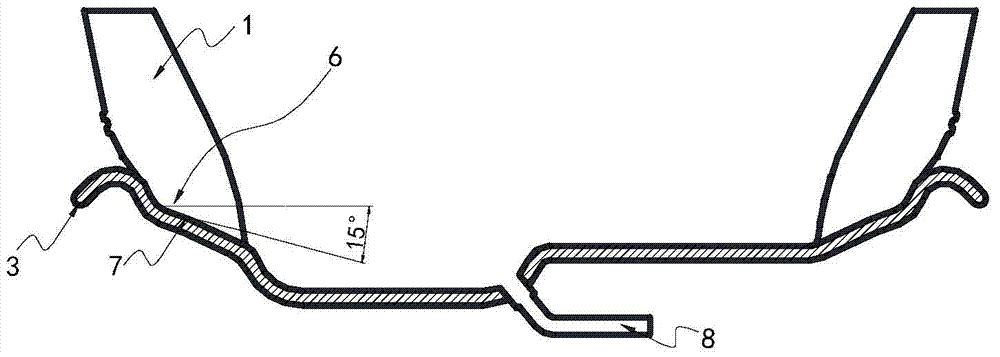

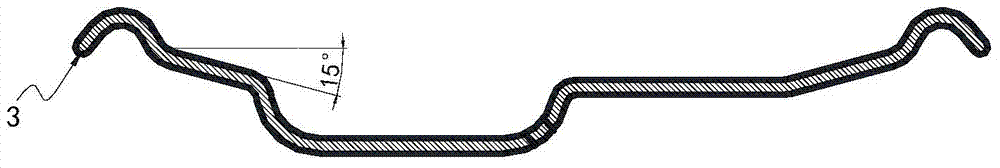

[0044] Such as Figure 3 to Figure 6c As shown, the wheel assembly for the truck of the present invention comprises a tubeless tire 1, a pad 4 and a rim 3, and it also includes an inner tube 5, which is assembled between the pad 4 and the tire 1 without a tube between;

[0045] The above-mentioned rim 3 is designed according to the bead size of the tubeless tire 1; the cushion strip 4 is designed with reference to the inner contour size of the rim 3 and the tubeless tire 1; the inner tube 5 is designed with reference to the inner contour of the tubeless tire 1, the size of the rim 3 and the cushion strip 4 Design; the position and size of the valve 8 of the inner tube 5 are designed with reference to the position and depth of the 8 holes of the valve on the rim 3;

[0046] For a better understanding of the present invention, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com