Wallpaper printing device

A printing and wallpaper technology, applied in decorative arts, embossed ornaments, etc., can solve the problem of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings of the embodiments.

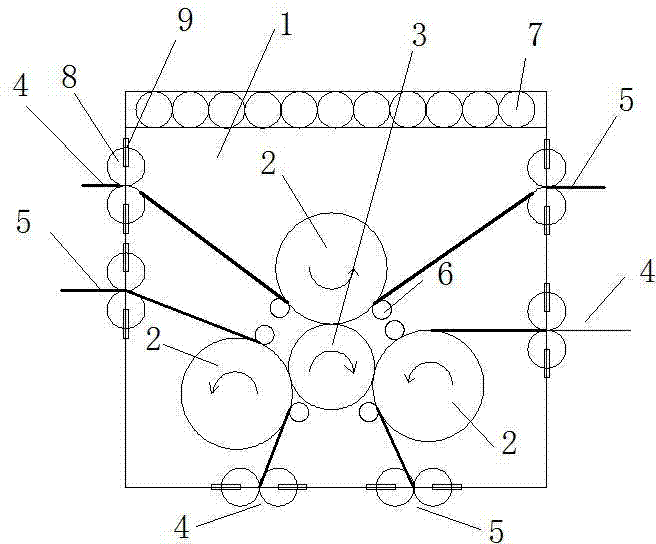

[0014] Such as figure 1 As shown, a wallpaper printing device of the present invention includes a box body 1, and a printing roller 2 is arranged in the box body 1; the number of the printing rollers 2 is 3, and the 3 printing rollers 2 are arranged in a triangular distribution, and the 3 printing rollers A rubber roller 3 is arranged in the middle of the embossing roller 2, wherein, the rotation directions of the three embossing rollers 2 are the same, and the rotation directions of the rubber roller 3 and the three embossing rollers 2 are opposite; the casing 1 is provided with a feed port 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com