A method for cutting Luzhou-flavor tobacco leaves with the content of petroleum ether extract as an evaluation index

A petroleum ether extraction and evaluation index technology, applied in tobacco, processed tobacco, food science, etc., to achieve the effect of improving economic value and use value, and improving overall utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

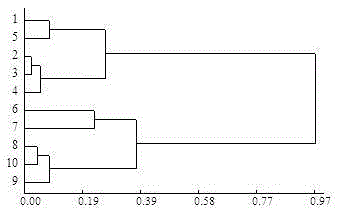

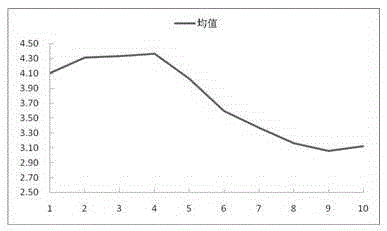

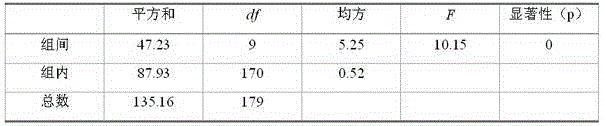

[0013] Take the single-material tobacco leaves Jiaxian Zhongyan 100B2F and Jiaxian Zhongyan 100C2F, and divide them into 10 sections from the tip to the base of the leaf, and number them from the tip to the base of the leaf as 1-10 to accurately measure the Jiaxian Zhongyan See Table 1 for the determination results of the petroleum ether extract content in ten regions of 100 B2F and C2F tobacco leaves.

[0014] Table 1 The content of petroleum ether extracts in different regions

[0015]

[0016] The average petroleum ether extract content of tobacco leaves of Jiaxian China Tobacco 100B2F tobacco leaves (3.38) was lower than that of Jiaxian China Tobacco 100C2F tobacco leaves (3.92), and the HN-1, HN -2, HN-3, HN-4, HN-5, the average petroleum ether extract content (4.09) was higher than that of Jiaxian Zhongyan 100C2F whole tobacco leaves. The No. 1~5 sections of Jiaxian China Tobacco 100B2F are divided into the first section, the No. 6-7 sections are divided into the s...

Embodiment 2

[0018] Take single-material tobacco leaves Lushiyun 87C3F and Kunmingyun 87C3F, divide them into 10 sections from the tip to the leaf base, and number them from tip to leaf base sequentially as 1-10, and accurately measure Lushiyun 87C3F and Kunmingyun respectively. The content of petroleum ether extract in ten areas of cut 87C3F tobacco leaves is shown in Table 2.

[0019] Table 2 The content of petroleum ether extracts in different regions

[0020]

[0021] The average petroleum ether extract content of the whole leaf of Lushiyun 87C3F tobacco leaves (4.11) was lower than that of Kunming Yun 87C3F whole tobacco leaves (4.52), and HN-1 and HN-2 of Lushiyun 87C3F after cutting , HN-3, HN-4, HN-5 five areas of petroleum ether extract content mean (5.01) was higher than the Kunming Yun 87C3F whole tobacco leaf petroleum ether extract mean. The No. 1~5 sections of Lushiyun 87C3F tobacco leaves were divided into the first section, the No. 6-7 sections were divided into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com