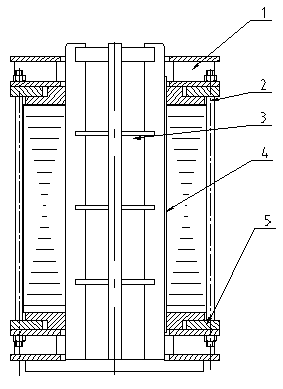

Novel lamination press mounting tire

A lamination and press-fitting technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of uncontrollable pressure between sheets, affecting the alignment of the magnetic center of the motor coil heat dissipation, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] Laminate the laminations on the lamination tire first, press the outside of the iron core through the pressure tire, and after the lamination tire is withdrawn, heat the iron core and thermally install it with the rotating shaft.

[0006] The design concept is based on the direction of operation safety and energy saving. It adopts low-cost and commonly used Q235B steel plate material. It uses equipment for blanking and welding, and then rough and finish machining on a lathe. It has a simple structure and strong versatility. Safe operation and reliable quality.

[0007] After a large number of motor 2 and 4 pole copper row rotors, the design is based on the size statistics of the non-tie rod iron core. It is suitable for the structure of the motor product, has good versatility and can meet the requirements of the inter-chip pressure. While ensuring product quality, it eliminates potential safety hazards, saves energy, and reduces production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com