Motor, fly-back control method of motor and energy circulation control method of motor

A technology of energy circulation and control method, applied in the direction of AC motor control, control system, motor generator/starter, etc., can solve problems such as energy consumption, and achieve the effect of reducing iron consumption and saving iron consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to describe the technical content, objectives and effects of the present invention in detail, the following descriptions will be made in conjunction with preferred embodiments.

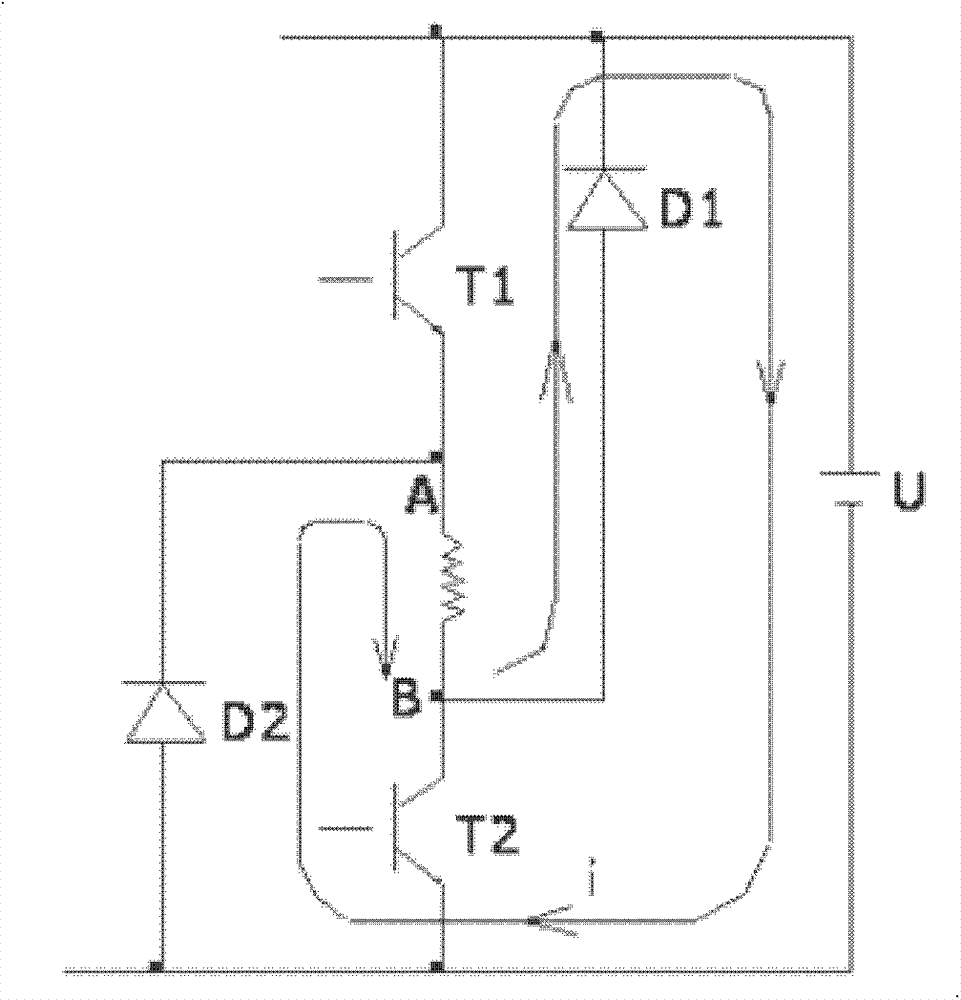

[0048] The invention relates to a new type of ultra-high-efficiency motor that combines flyback motor control technology and energy circulation (regeneration) technology. In the invention, the working principle, structural design, and control mode of the motor are different from traditional motors. , its characteristics and effects are also quite different from traditional motors, especially the motor does not use any permanent magnet materials, so it has great practical significance for energy saving, emission reduction, and protection of rare resources.

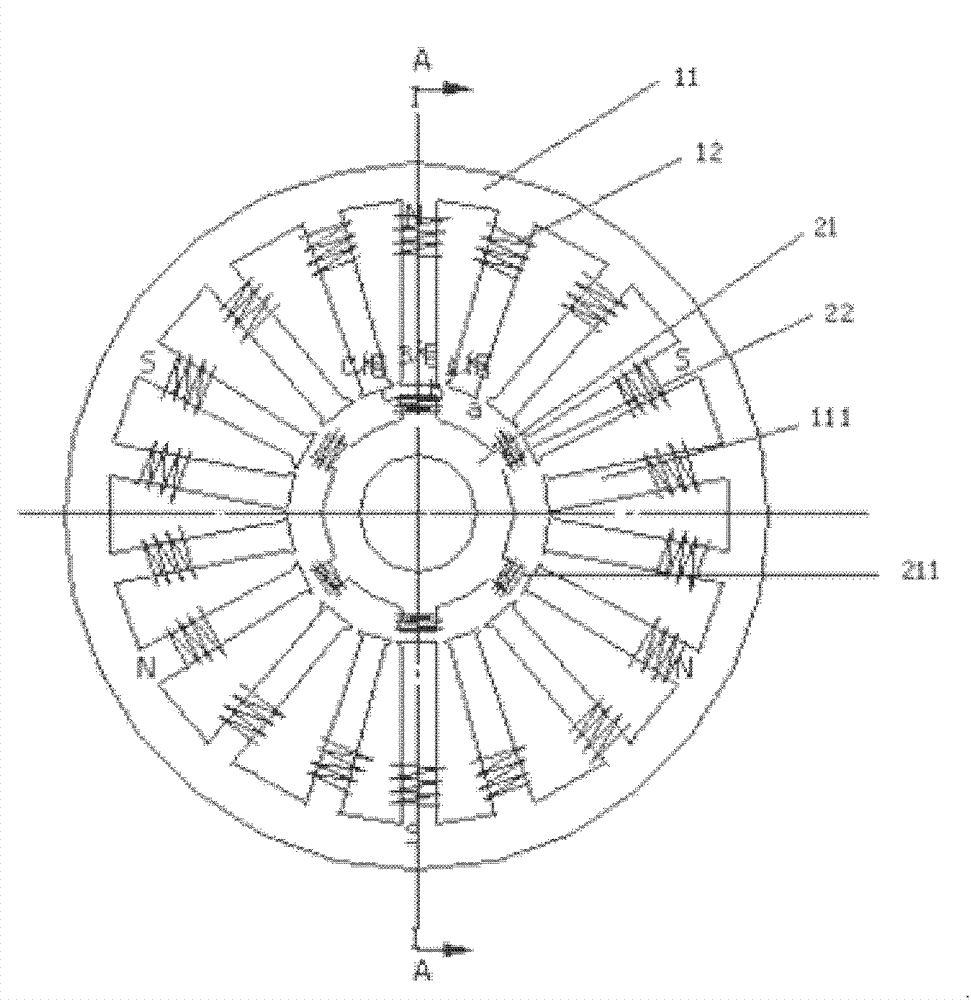

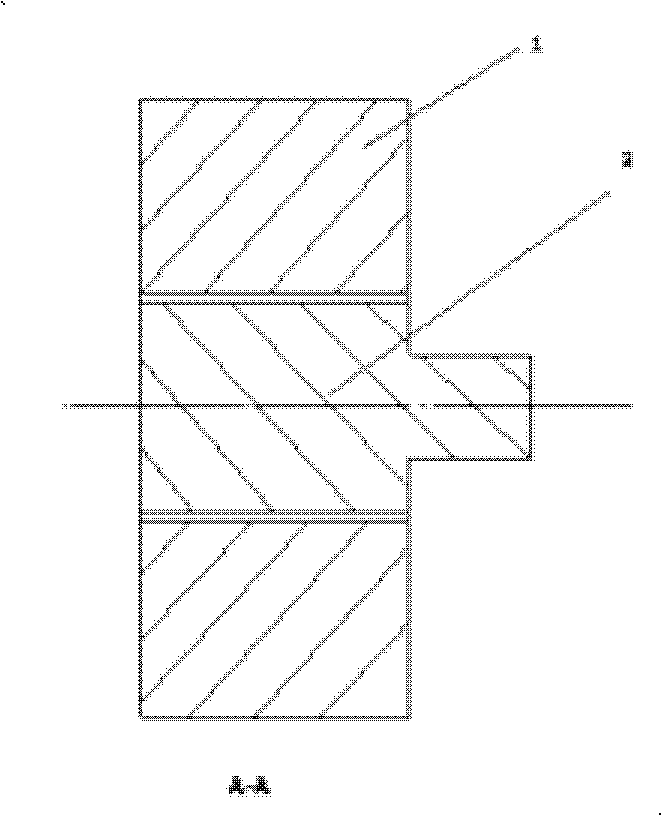

[0049] combine figure 2 and image 3 , first introduce the specific structure of the motor of the present invention: the motor includes two parts, a stator 1 and a rotor 2, the stator 1 includes a stator core 11 and a stator coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com