Stator of rotary motor

A technology for rotating electrical machines and stators, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc. It can solve problems such as loosening, deformation of the inner and outer diameters of stator cores, and adverse effects on motor performance, so as to improve material utilization and production efficiency , Conducive to the control of dimensional accuracy or positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

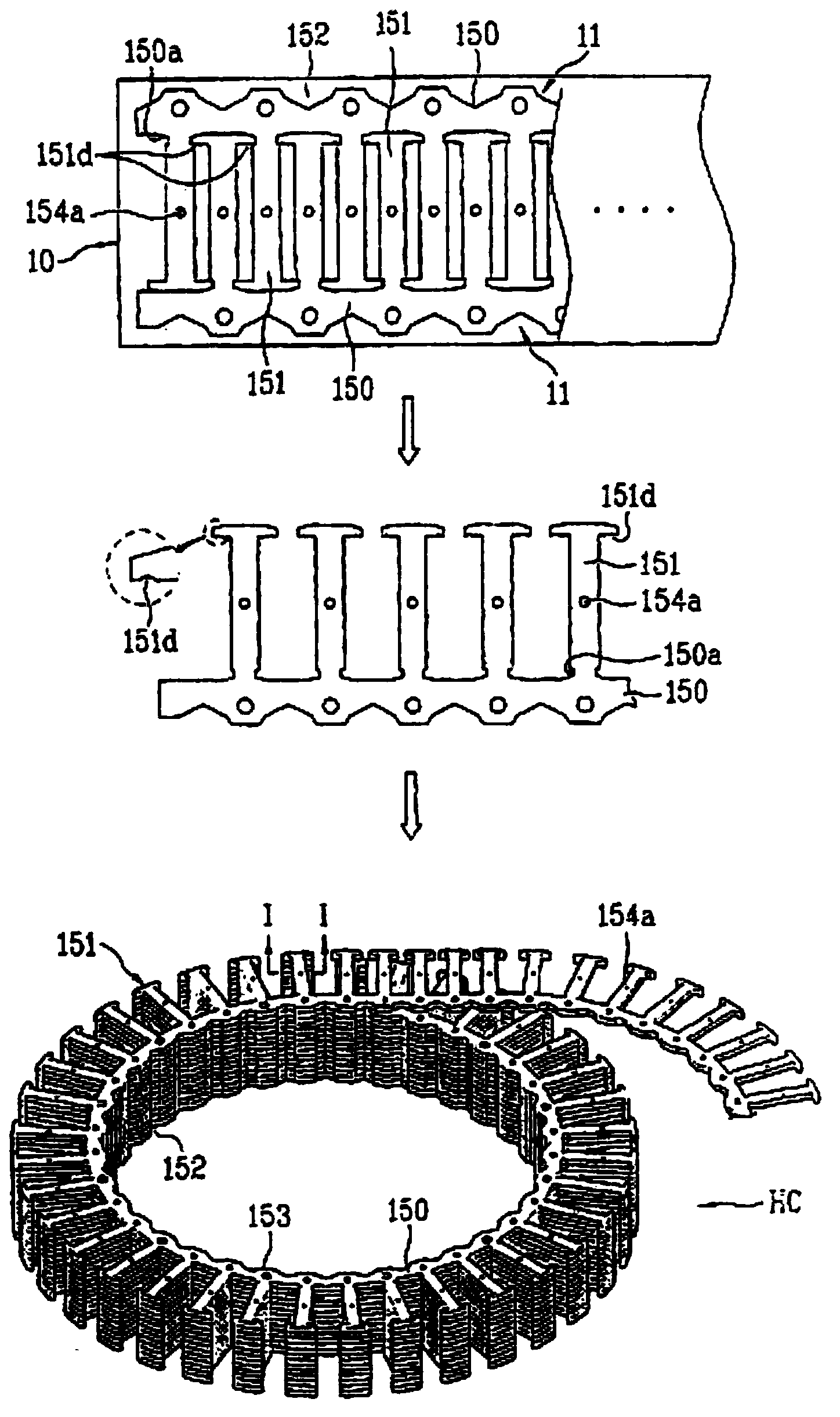

Method used

Image

Examples

no. 1 example

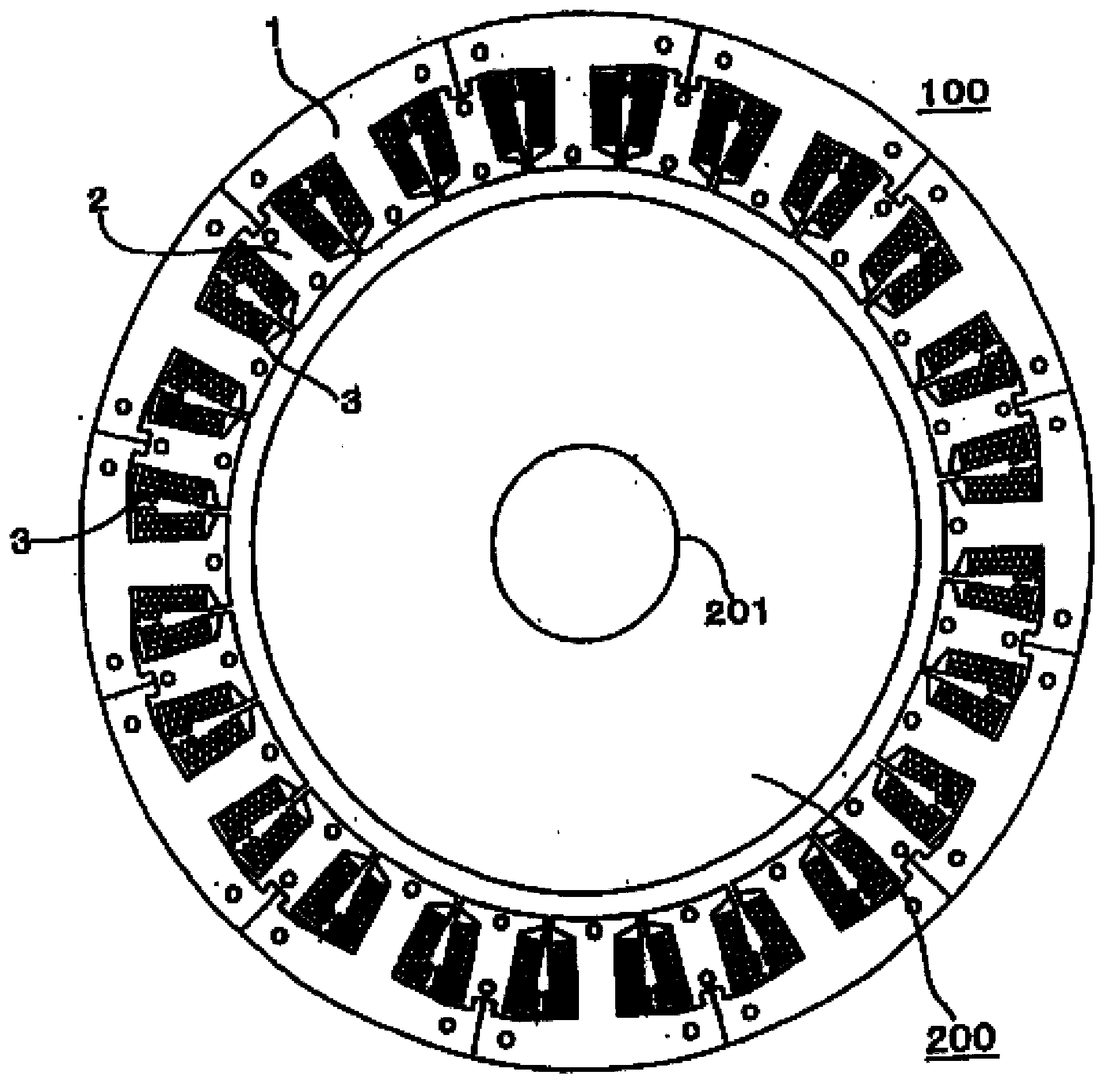

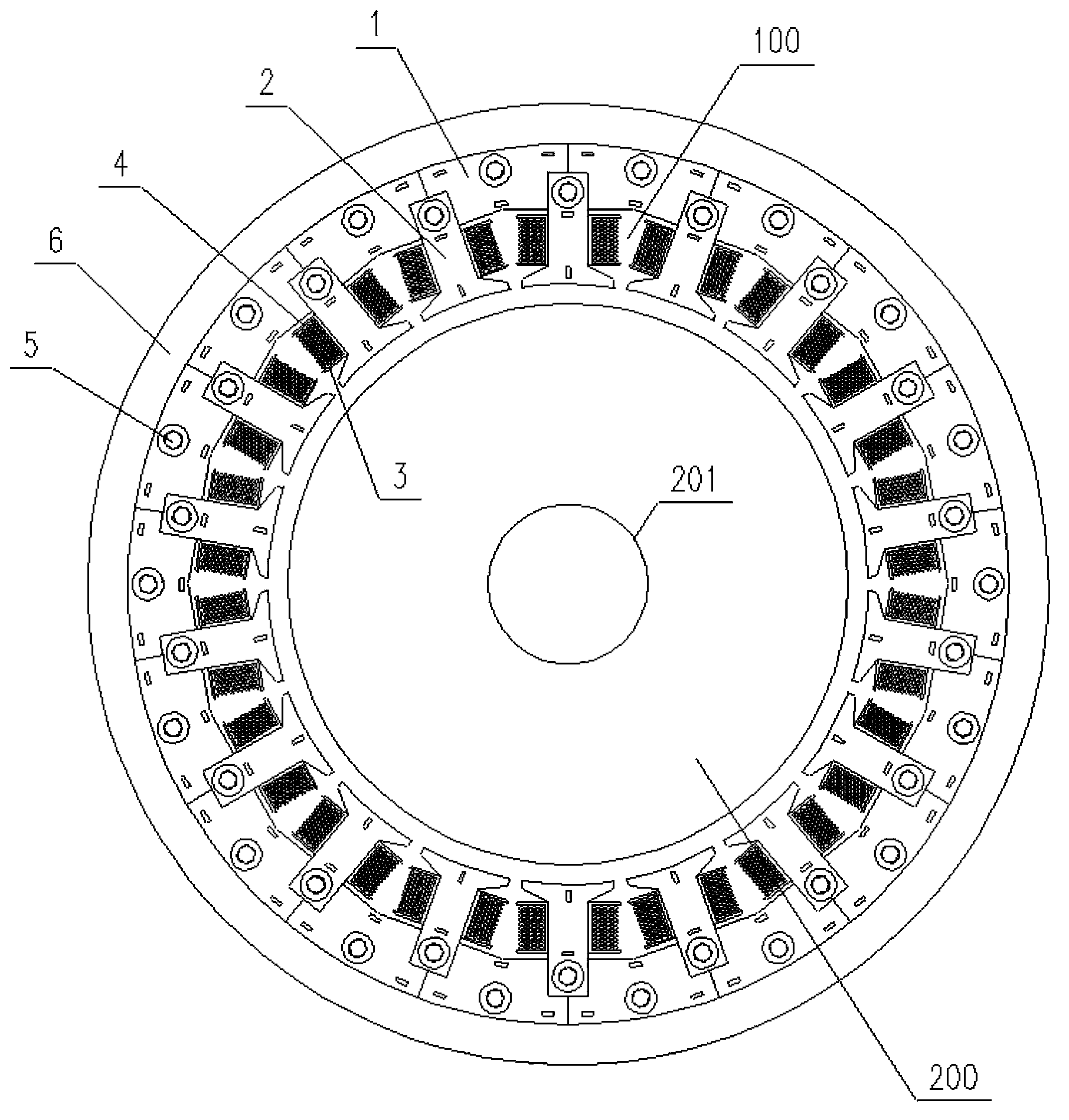

[0046] Such as image 3 Shown is the first embodiment of the stator of the rotating electrical machine of the present invention, the rotating electrical machine includes a stator 100, a rotor 200 mounted on a rotating shaft 201, the stator 100 and the rotor 200 are arranged opposite to each other through a prescribed gap.

[0047] Such as image 3 , Figure 4 As shown, the stator 100 of the rotating electrical machine includes a stator yoke 1, a stator tooth 2, a coil 3, an insulator 4, a mounting plate 6 and a plurality of fasteners 5, and in this embodiment, both the stator yoke 1 and the stator teeth 2 are 18 indivual.

[0048] The stator tooth 2 is formed by stacking steel plates of the shape shown in the figure according to the required number, and is integrally formed by punching and riveting interface 2b. The convex top 2c of the stator tooth has a mounting hole 2d along the axial direction, such as Figure 6 shown.

[0049] Same as the stator teeth 2, the stator y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com