High-sheet-resistance safe metallized film

A metallized thin film, high square resistance technology, applied in the direction of fixed capacitor electrodes, fixed capacitor parts, etc., can solve the problems of not ideal self-healing, large volume, insufficient energy storage density of capacitors, etc., to improve self-healing ability , Increase the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The content of the present invention will be described below in conjunction with specific embodiments.

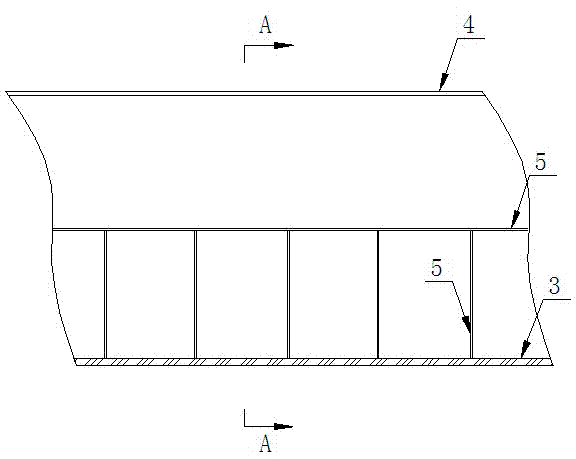

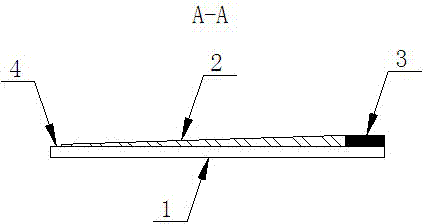

[0012] Such as figure 1 Shown is a schematic diagram of the structure of the high square resistance safety metallized film of the present invention, figure 2 for figure 1 Middle A-A sectional view. The metallized film of the present invention comprises: a base film 1 , a thickening area 3 , a gradient resistance area 2 , a margin 4 , and a metal fuse 5 . A layer of metallic zinc is plated on one side of the base film 1 , so that a relatively thick layer of zinc coating is formed on the edge of the base film 1 to form a thickened region 3 . The thickened region 3 greatly reduces the contact resistance between the gold-sprayed layer and the core of the film capacitor, and can withstand a relatively large current. Control the thickness of the vapor-deposited metal zinc in the thickened area 3 so that the sheet resistance presented is within (4.5±1) Ω / □.

[0013] O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com