Wire winding glue-injection machine for thread coils

A technology of glue injection machine and winding mechanism, which is applied in the direction of coil manufacturing, coating, and surface coating liquid device, etc. It can solve the problems of increasing the workload of grinding and polishing, affecting the quality of coils, and high labor intensity, so as to achieve high efficiency. Winding and glue injection operations, improving labor efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings; the examples given are only for explaining the present invention, and are not intended to limit the scope of the present invention.

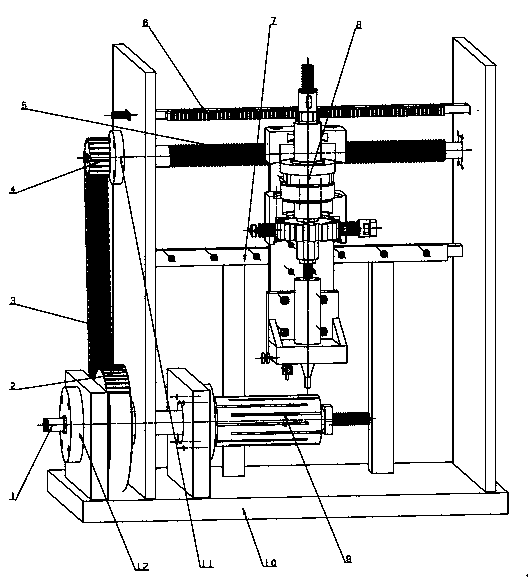

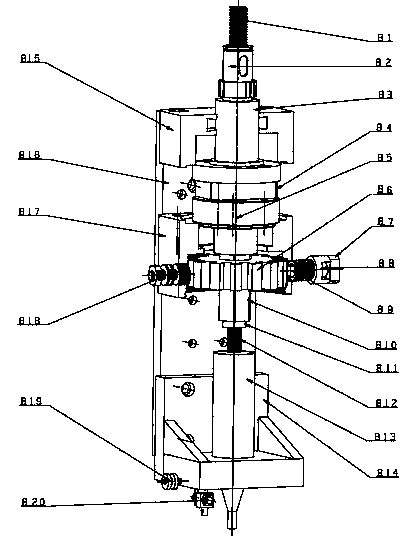

[0018] Embodiment 1, see 1, 2, 3, select components with appropriate specifications according to design requirements, and process them into frame 10;

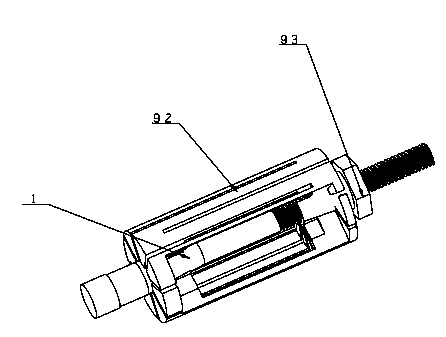

[0019] The main transmission shaft 1 is connected to the frame 10 through bolts through the second bearing and bearing seat 12, the large synchronous pulley 2 is fixedly connected to the main transmission shaft 1 through a flat key, and a fixed timing belt 3 and a small synchronous pulley 4 are formed. Compared with the transmission pair, the small synchronous pulley 4 is fixedly connected with the first ball screw 5 through the flat key; the first ball screw 5 is connected with the frame 10 through the first bearing and the bearing seat 11, and then the first ball screw The nut of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com