Flat coil inductor, flat coil and manufacturing method of flat coil

A technology of flat coils and inductors, applied in the field of inductors, can solve the problems of small magnetic core space, flat coil width cannot be made too wide, low DC resistance, high saturation current electrical characteristics, etc., to achieve convenient folding The effect of processing and overall smooth lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

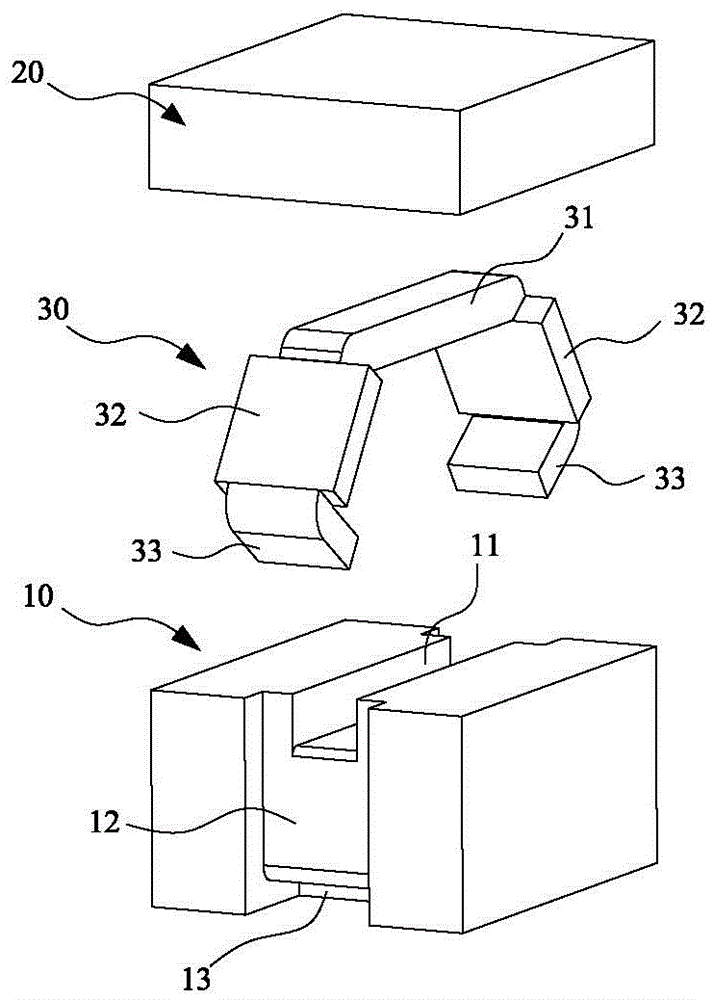

[0045] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the first embodiment of the present invention. The flat coil inductor includes a magnetic core 10 , a magnetic cover 20 and a flat coil 30 .

[0046] Wherein, the magnetic core 10 is provided with a first groove 11 at the top, a second groove 12 at both sides, and a third groove 13 at the bottom. The magnetic cover 20 covers the top of the magnetic core 10 .

[0047] The flat coil 30 is made of pure copper material, which is wound on the magnetic core 10. The flat coil 30 includes a top base 31, two sides flattened parts 32 and a bottom bottom flattened part 33. The portion 33 is formed by turning and extending the lower edge of the flattened portion 32 on both sides inwardly or by flattening for a second time to become thinner. The base 31 is embedded in the first groove 11 between the magnetic core 10 and the magnetic cover 20, and the flattened parts 32 on both sides are embedded in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com