A closed-loop evaluation method and system for pipe body defects of long-distance oil and gas pipelines

A technology for oil and gas transportation and pipelines, which is applied in the field of closed-loop assessment of pipe body defects in long-distance oil and gas pipelines, and can solve problems such as failure to provide reliable data support for business management, unfavorable closed-loop assessment, and occupation of system resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

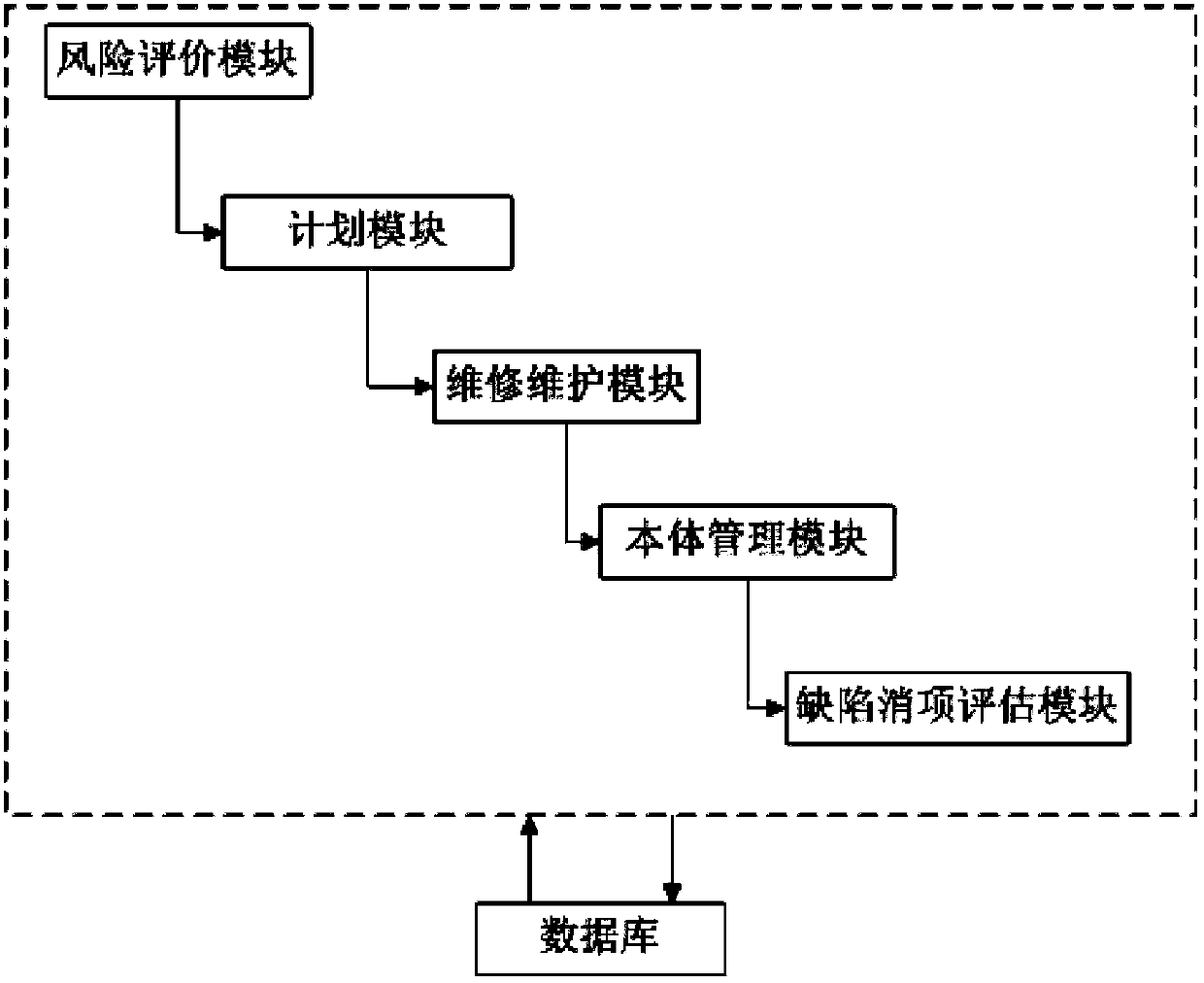

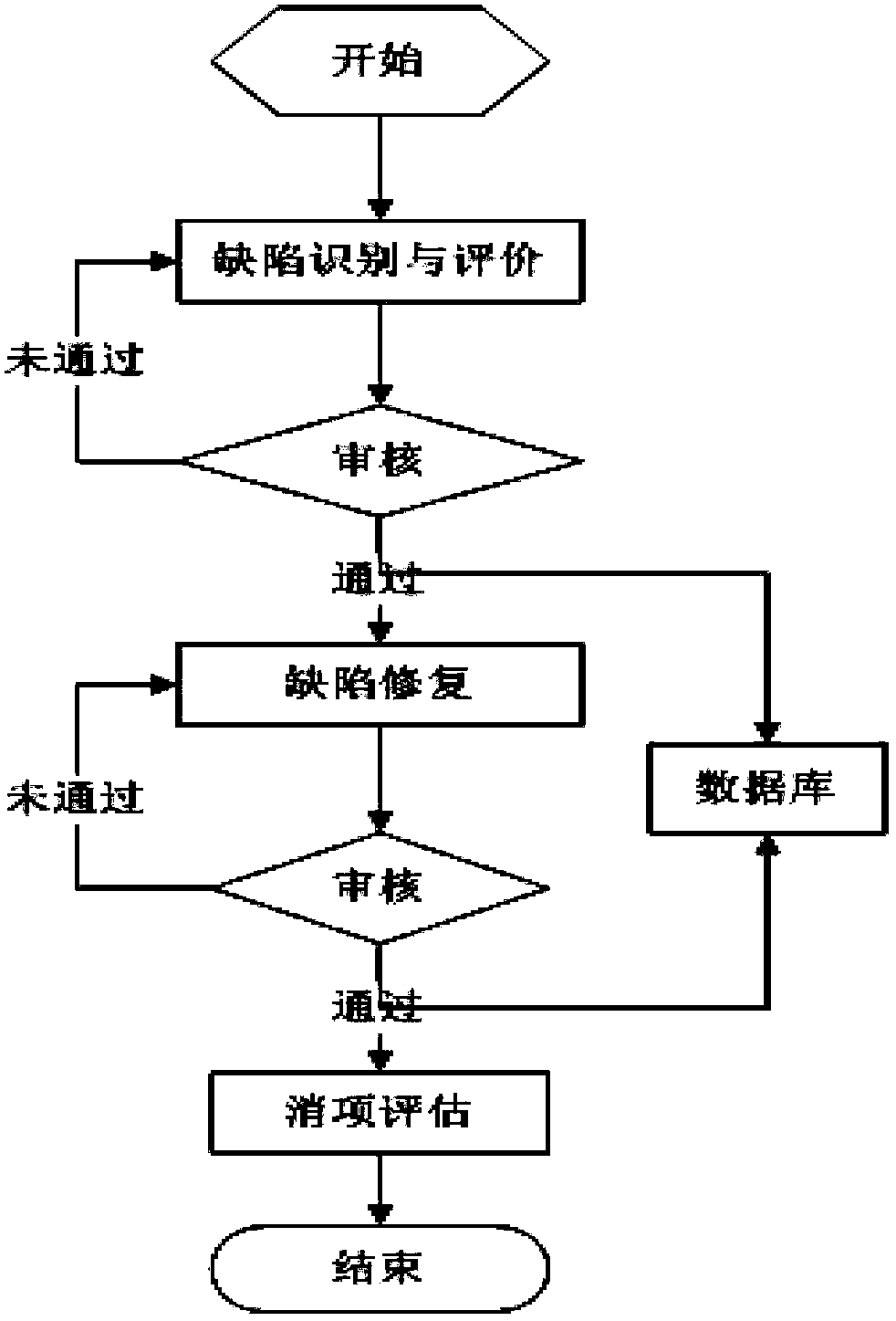

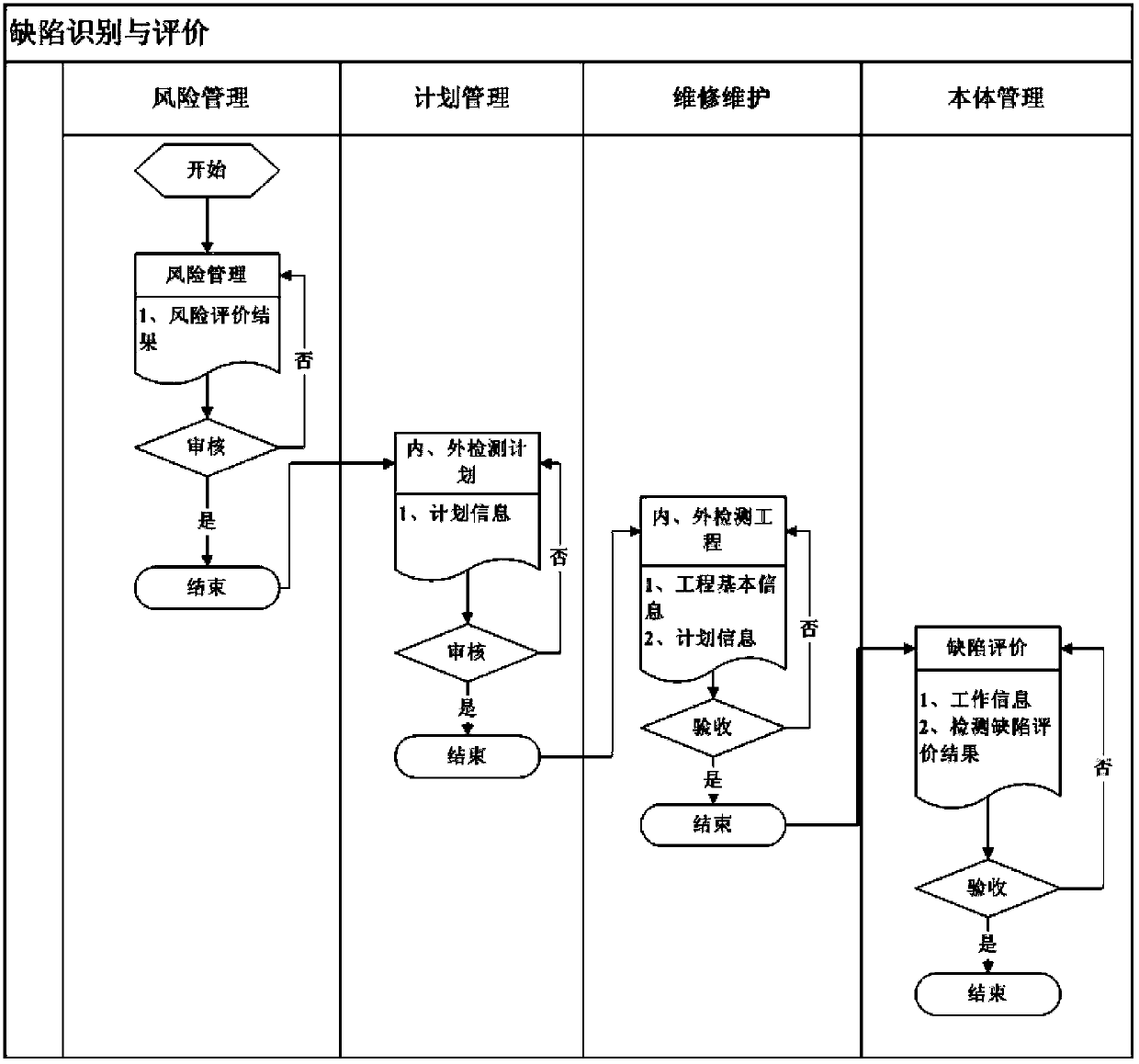

[0101] Examples. This example provides a closed-loop assessment method for long-distance oil and gas pipeline body defects. The main design idea is: to link defect identification and evaluation, defect repair and elimination evaluation according to business relationships, to achieve full life cycle monitoring of defects, and achieve Closed loop evaluation.

[0102] Among them, the typical business association portfolio is: the association between risk and investment plan, the association between investment plan and engineering, and the association between business activities and defect elimination assessment. The method of the present invention will be described in detail below with this typical related business as an example.

[0103] The business of the present invention mainly includes: risk assessment, planned investment management, repair and maintenance, ontology management, and defect elimination evaluation. By executing these business requests, business associations can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com