Optimum design method of drawing processing technology locus of servo press

A servo press, optimized design technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of reduced stamping production cycle and poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Example 1: figure 1 It is the CAD model of the side wall outer panel of a certain car model, and its drawing forming process parameters are as follows: the drawing height is 200mm, the slider speed is required to be lower than 300mm / s at the beginning of drawing, the draft height is 5mm, and when the drawing ends The speed of the slider is lower than 50mm / s, the height of the safe space for manipulator transmission is not lower than 700mm, the transmission time is not lower than 2s, the maximum speed of the slider is lower than 1800mm / s, and the maximum acceleration is lower than 4500mm / s 2 .

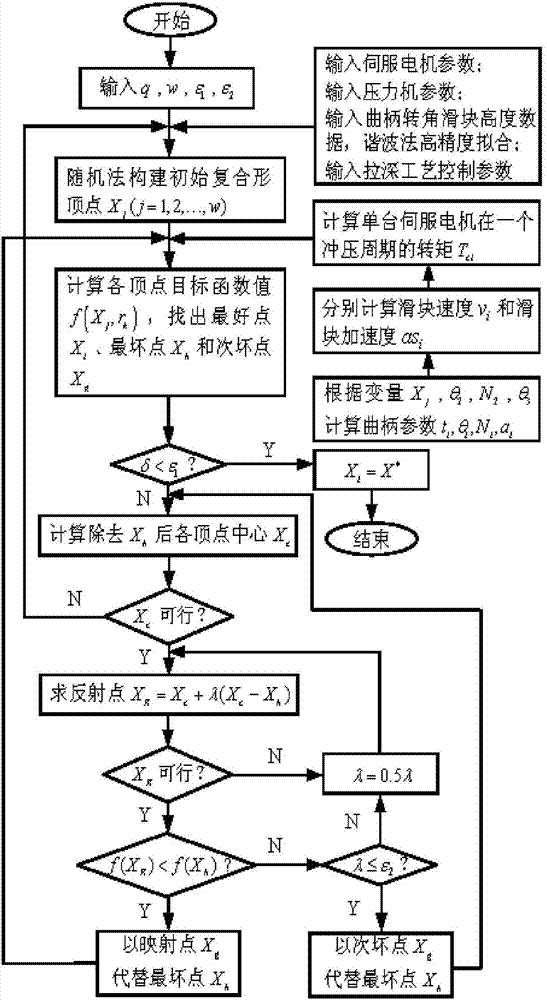

[0087] figure 2 It shows a flow chart of an optimal design method of a servo press drawing processing trajectory of the present invention. The optimal design method of the servo press deep drawing process trajectory of the present invention comprises the following steps:

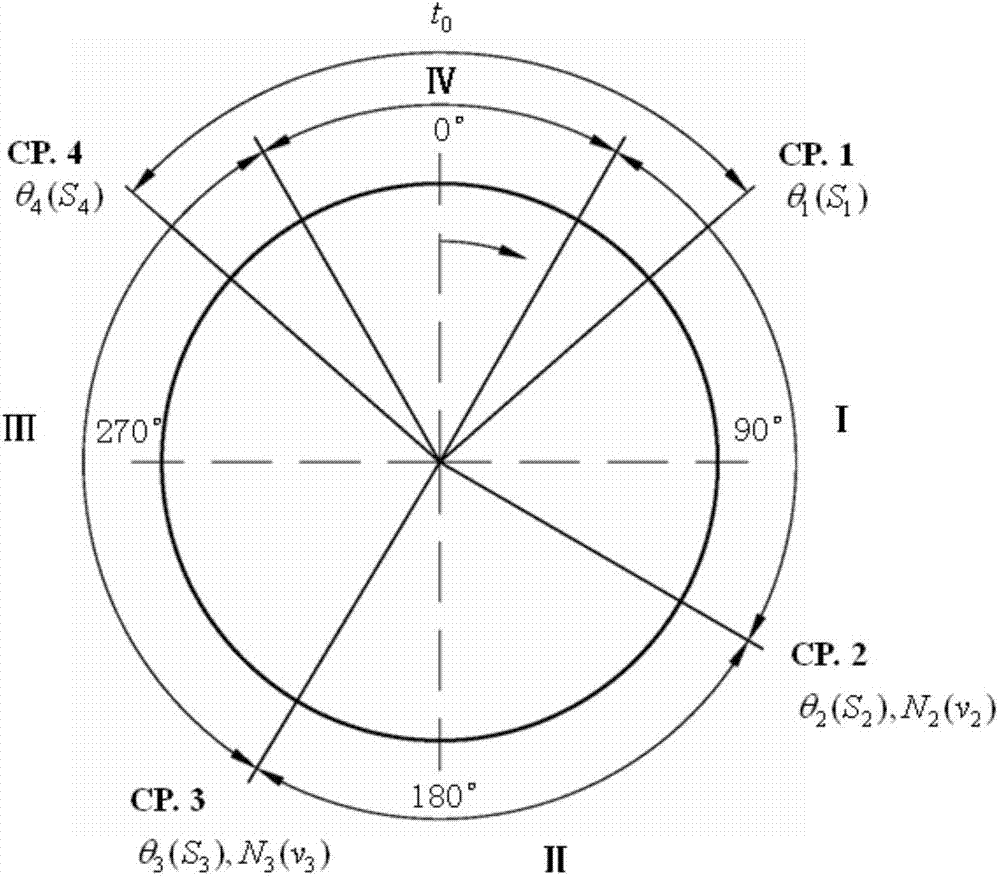

[0088] (1) Establish the kinematics model of the servo press transmission mechanism by using MSC's mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com