Split type freezing and thawing testing machine

A testing machine, split technology, applied in the direction of analyzing materials, material thermal analysis, measuring devices, etc., can solve the problems of uneven temperature in the test box, increase test errors, and differences in the temperature of concrete specimens, so as to avoid the existence of temperature Difference, improve uniformity, and the effect of accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

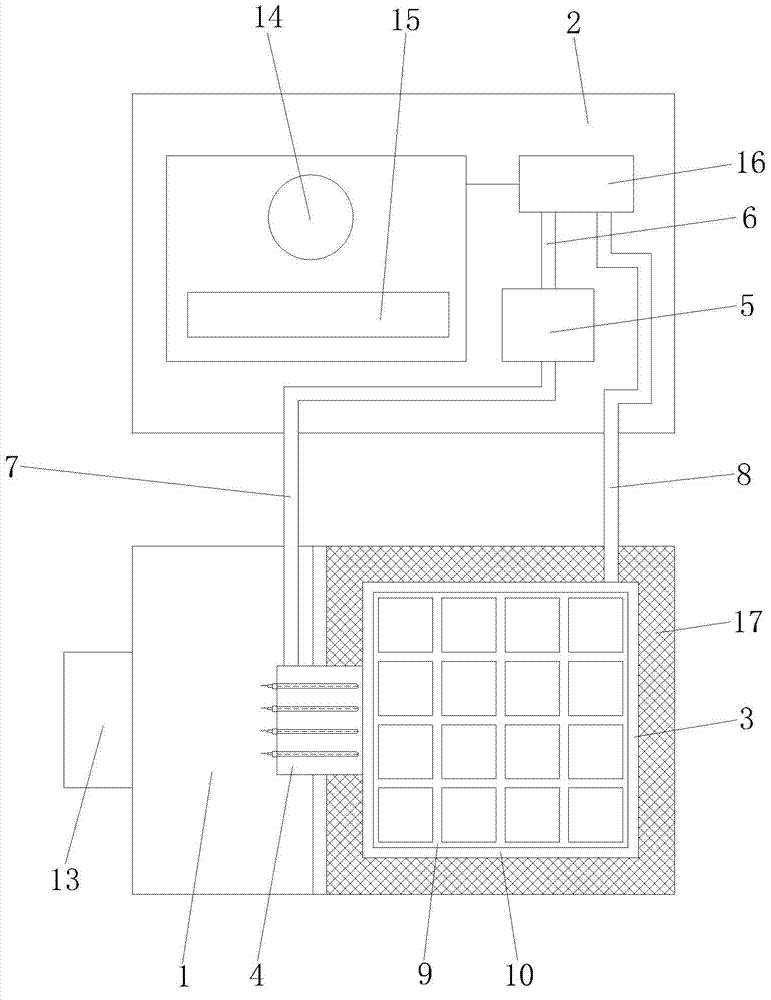

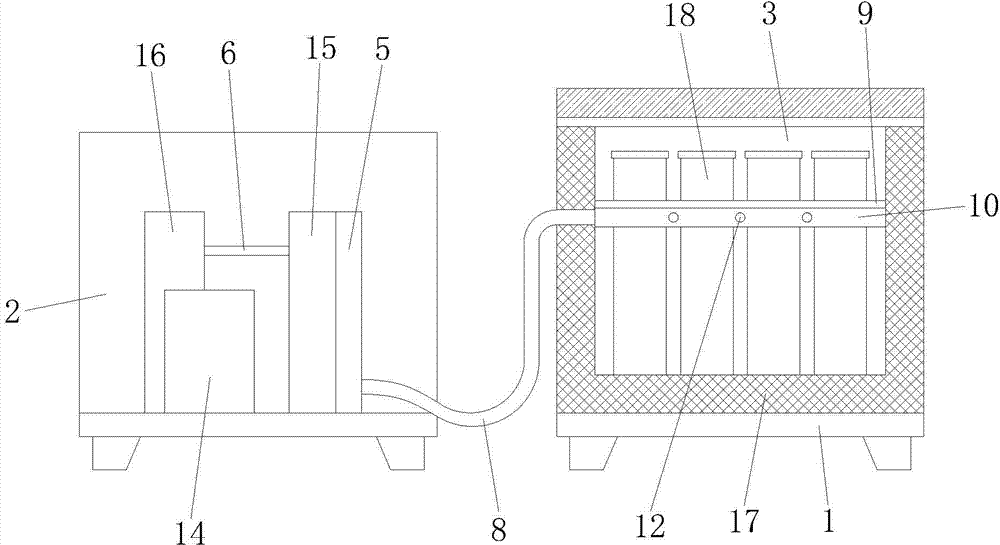

[0018] The present invention is described below in conjunction with accompanying drawing.

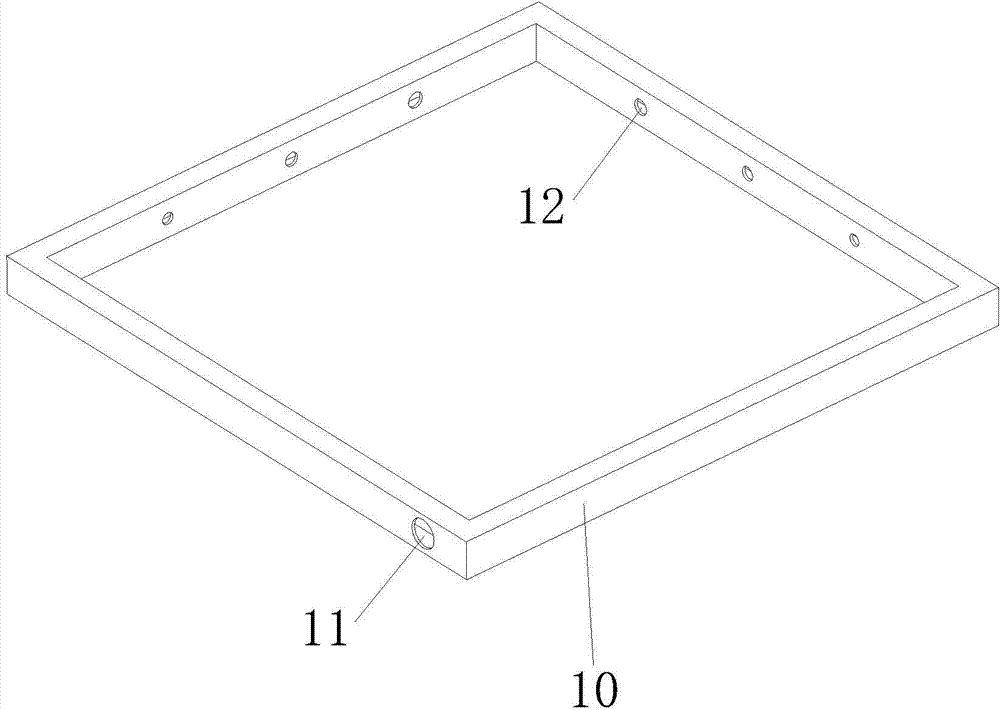

[0019] as attached figure 1 , 3 The shown a kind of split type freeze-thaw tester of the present invention comprises main box body 1 and outdoor unit 2; Described main box body 1 is provided with test piece box 3 and heating device 4; Said heating device 4 The side of the test piece box 3 is set, and communicates with the inside of the test piece box 3 through pipelines; the outdoor unit 2 is provided with a refrigeration unit and a water pump 5; the refrigeration unit and the water pump 5 are connected through a first pipeline 6; The heating device 4 is connected with the water pump 5 through the second pipeline 7; the test piece box 3 is connected with the refrigeration device through the third pipeline 8; the test piece box 3 is provided with a grid 9; Concrete test piece box 18 is provided; Described test piece box 3 is also provided with the diversion tube 10 that is connected en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com