Large triaxial shear testing instrument for rockfill material degradation

A technology of triaxial shearing and rockfill material, which is applied in the field of large-scale triaxial shearing tester for rockfill deterioration, can solve problems such as excessive scaling effect, inability to measure volume deformation, inability to carry out complex stress path test research, etc. Achieve accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical means, innovations and main functions of this invention will be further elaborated below in conjunction with specific illustrations.

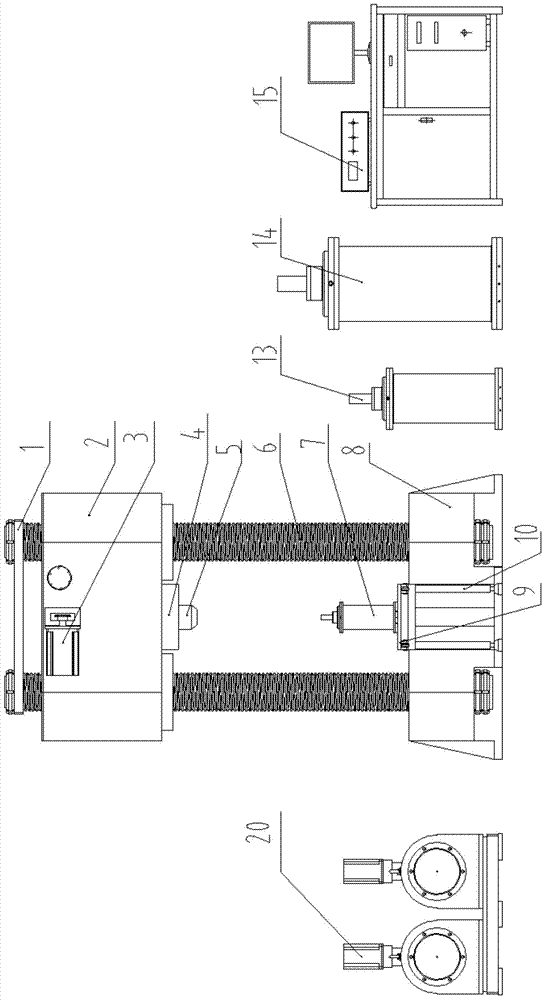

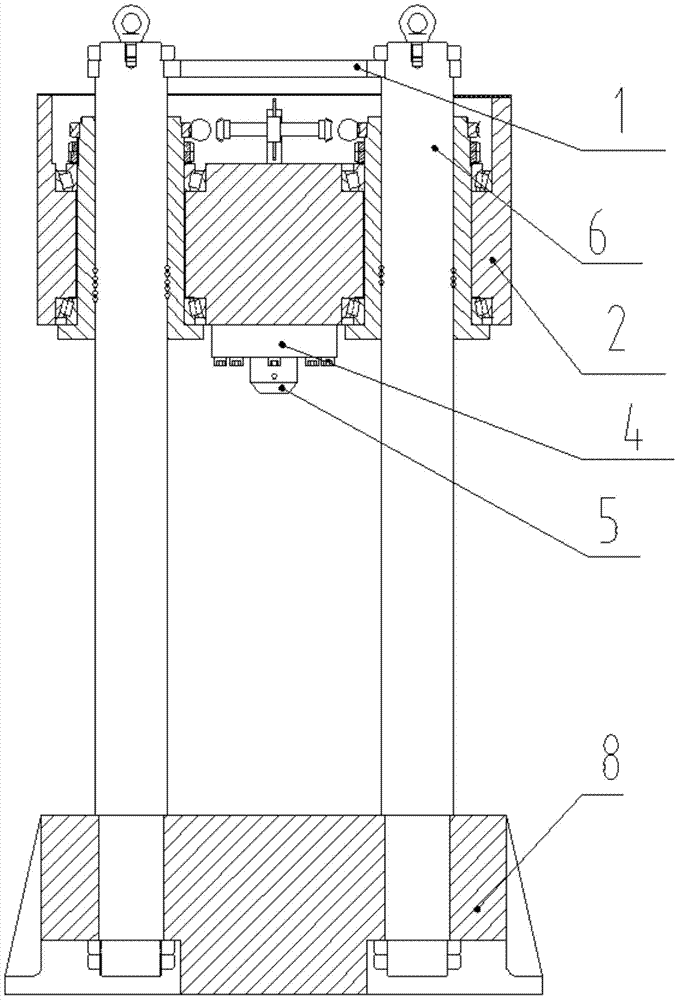

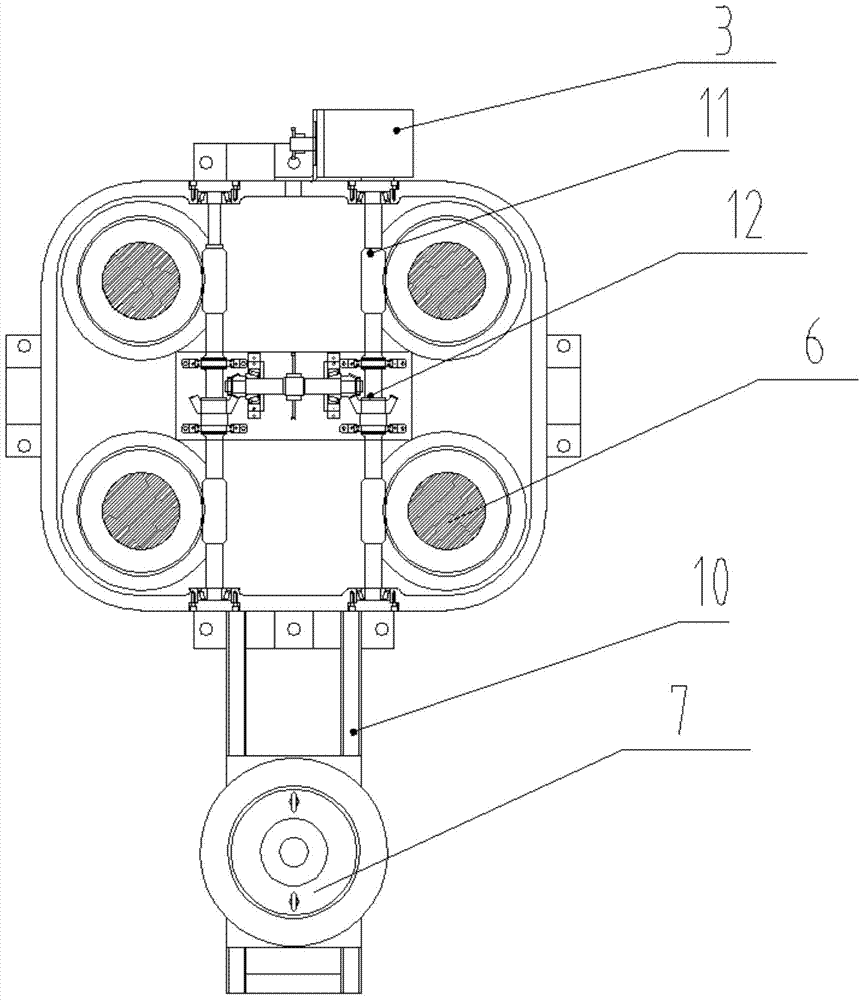

[0032] Such as Figure 1~3 As shown, a large-scale triaxial shear tester for rockfill material deterioration includes a test host, a servo loading system for confining pressure and pore pressure, a temperature control system, a closed-loop measurement and control system, and a computer control and data acquisition system 15; the confining pressure and pore pressure The pore pressure servo loading system pressurizes the loading medium to the specified pressure, and then connects the pressure chamber of the test host through the confining pressure booster hole and the water seepage hole to apply confining pressure to the sample; the temperature control system heats or cools the loading medium to a certain temperature; the closed-loop measurement and control system includes a multi-channel closed-loop measurement and control i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com