Cement preheater internal cylinder hanging sheet

A cement preheater and inner cylinder technology, which is applied in the directions of preheating cost, lighting and heating equipment, furnaces, etc., can solve the problems of weakening wind speed and affecting the service life of coupons, so as to increase the service life, increase the cement output, and increase the wind speed. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

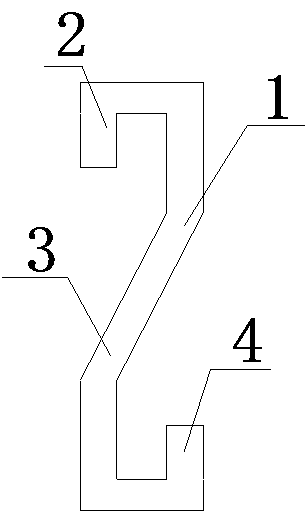

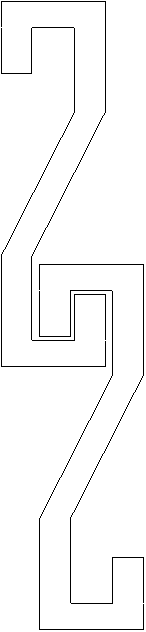

[0012] The cement preheater inner tube hanging piece of the present embodiment, such as figure 1 As shown, the hanger is S-shaped with a center symmetry, and its upper half includes the upper arm 1 and the upper hook 2 extending from the top of the upper arm 1 to one side of the hanger; the lower half of the hanger includes the lower arm 3 and the lower arm 3. 3. The lower hook 4 extending from the bottom end to the other side of the hanging piece.

[0013] The coupon in this embodiment is made of a heat-resistant steel, and its composition is as follows: Ni: 10%; Cr: 26%; Si: 1.4%; C: 0.35%; Mo: 0.4%; W: 0.4%; Mn: 1%; N: 0.14%; Re: 0.005%; the balance is iron. The heat-resistant steel used in this embodiment uses carbon, nitrogen and a small amount of nickel as austenite elements to form an austenite matrix. In this embodiment, higher carbon elements are added to expand and stabilize the austenite and reduce the nickel content. At the same time, due to the carbide dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com