Switch assembly of urban rail vehicle sliding door

A technology of urban rail and switch components, which is applied to door/window accessories, wing leaf parts, contact operating parts, etc. It can solve problems such as time-consuming and labor-intensive, micro-switches cannot be reset, and springs are prone to fatigue and fracture, so as to eliminate sticking Phenomenon, good application prospects, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

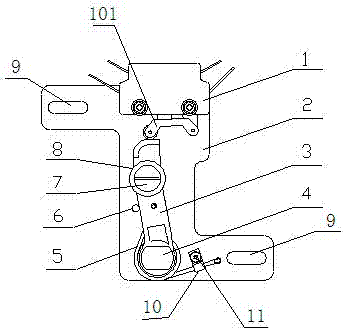

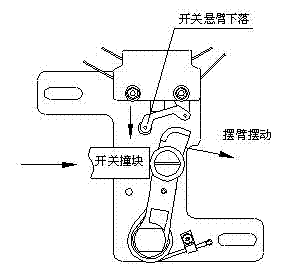

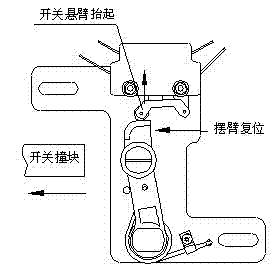

[0015] Such as figure 1 As shown, the switch assembly of the urban rail vehicle sliding door of the present invention includes a micro switch 1, a mounting base plate 2, a swing arm 3, a rotating shaft 4, a torsion spring 5, a limit pin 6 and a roller 8, and the mounting base plate 2 is a Z-shaped shape, the bend is a right-angle transition, and the front and rear ends of the installation base plate 2 are provided with waist-shaped fixing holes 9 for easy fixing. The micro switch 1 is fixed above the installation base plate 2, and the micro switch 1 is directly below the The rotating shaft 4 is fixed on the installation base plate 2, and the torsion spring 5 is sleeved on the rotating shaft 4, and one end of the torsion spring 5 is fixed on the installation base plate 2 on the side of the rotating shaft 4, and one end of the torsion spring 5 is sleeved with a fixed rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com