Gas collection and storage device for biogas digester

A technology for gas storage devices and biogas digesters, which is applied to gas production bioreactors, biochemical instruments, and biological sludge treatment, etc., can solve problems such as safety accidents, gas leakage in biogas digesters, and steel plate damage, and achieve cost reduction, The effect of increasing the service life and facilitating storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

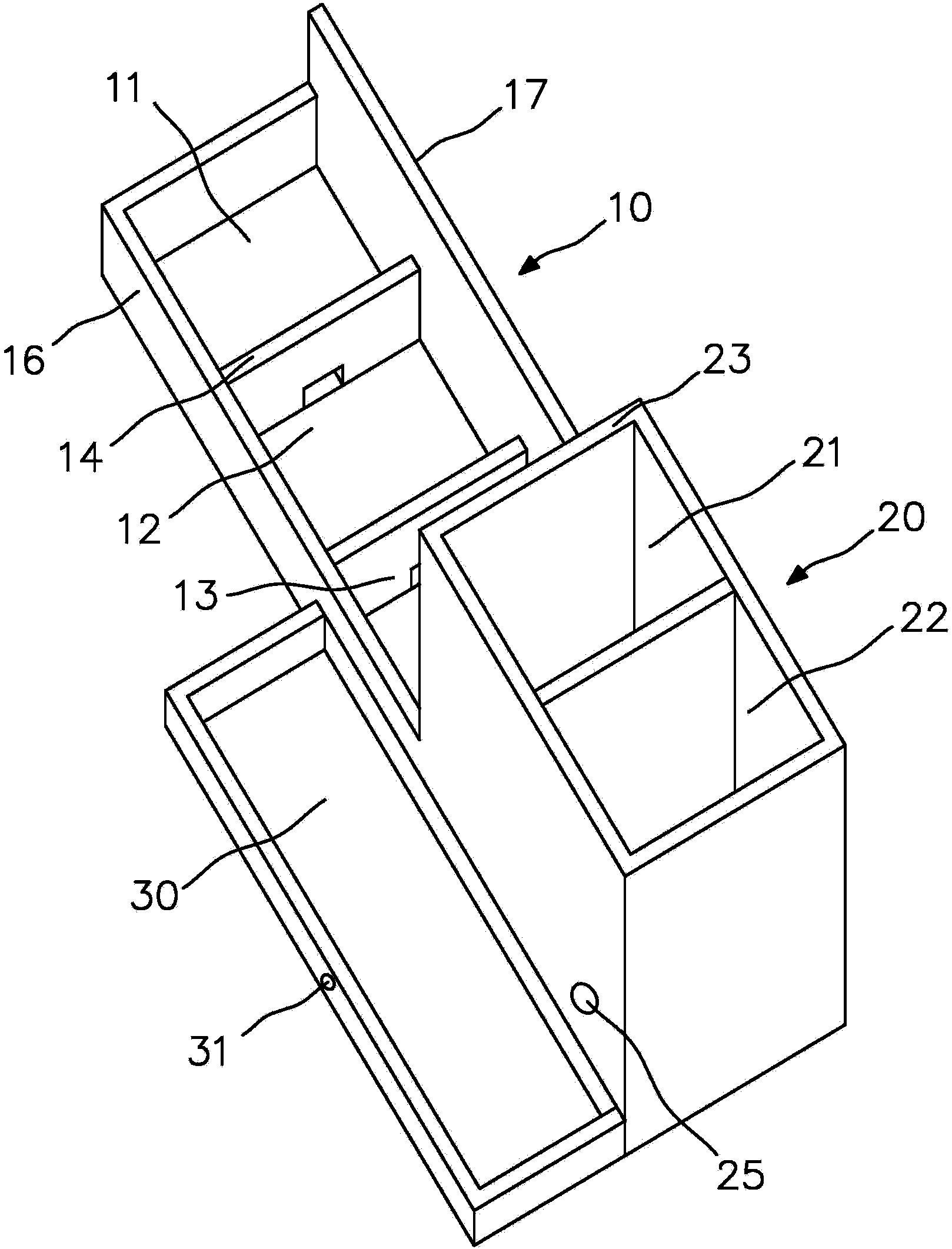

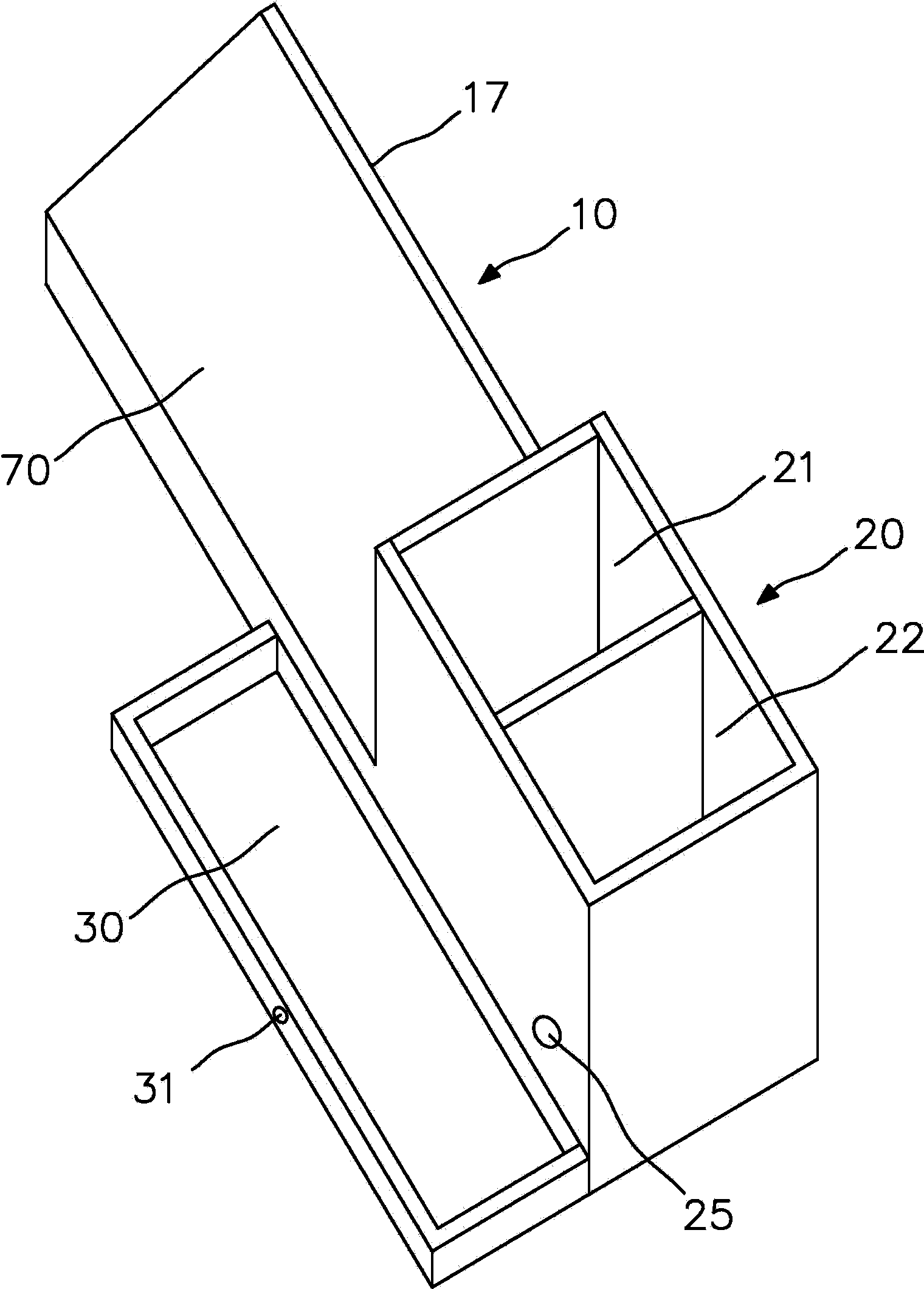

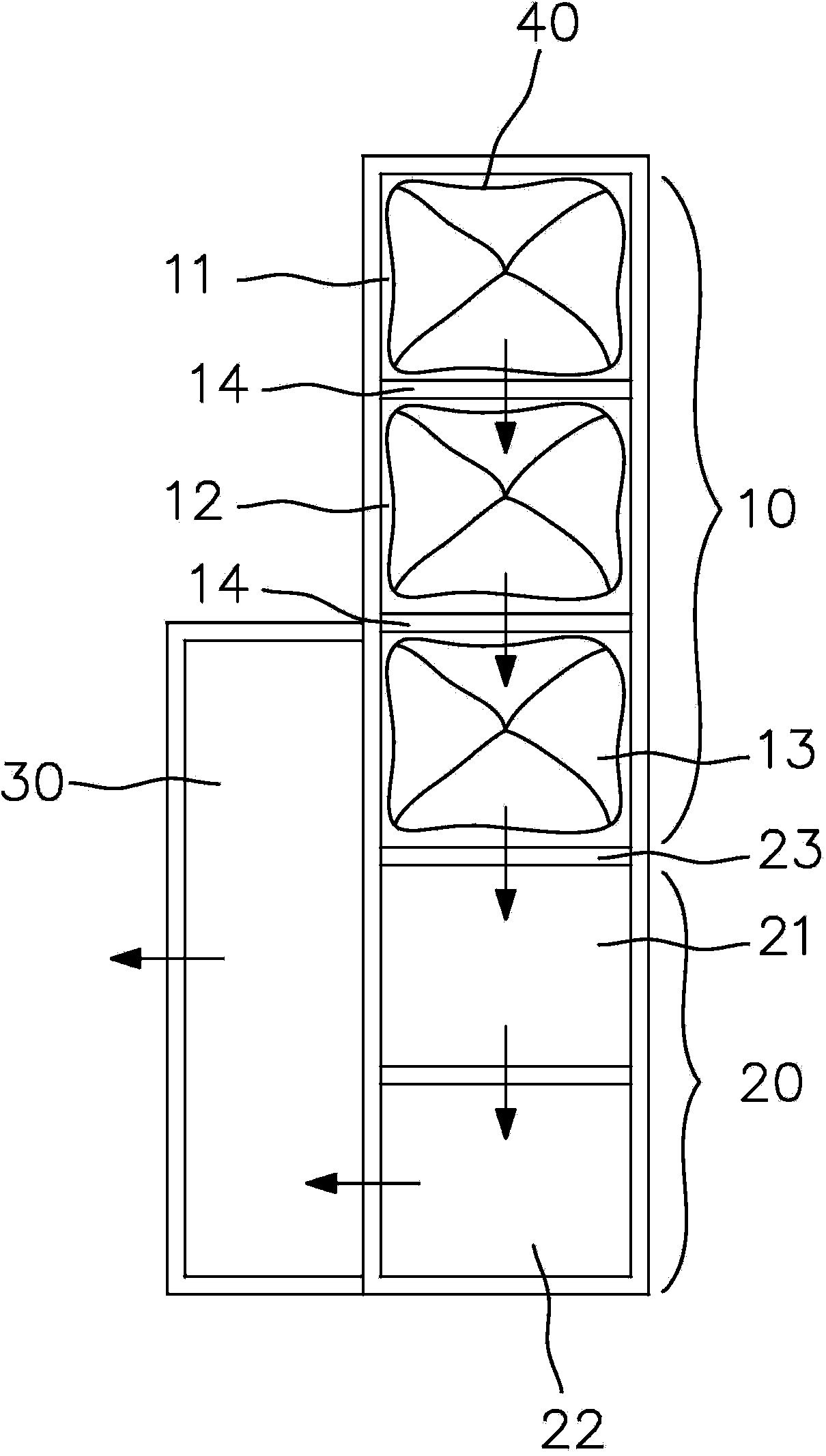

[0032] Such as figure 1 As shown, a resource comprehensive utilization system for processing poultry manure, which includes the following components:

[0033] The biogas generating unit 10 comprises a first biogas digester 11, a second biogas digester 12 and a third biogas digester 13 adjacent in sequence, between the first biogas digester 11 and the second biogas digester 12 and between the second biogas digester 12 and the second biogas digester 12. An inner partition wall 14 is arranged between the third biogas digesters 13, and the lower part of the inner partition wall 14 is provided with a communication port 15 communicating with adjacent biogas digesters; from the first biogas digester 11, the second biogas digester 12 to the third The bottom elevation of the biogas di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com