Leather detergent

A cleaning agent and leather technology, applied in the field of cleaning agents, can solve the problems of poor comfort, leather hardening, volatilization and loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

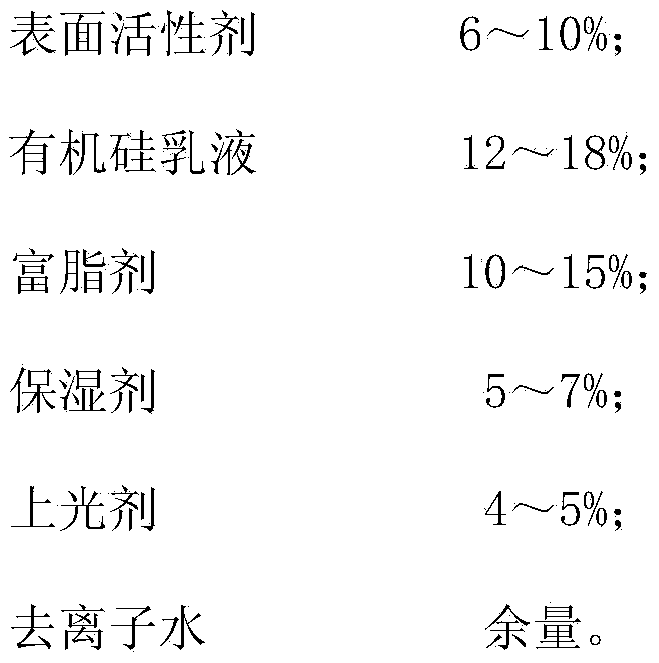

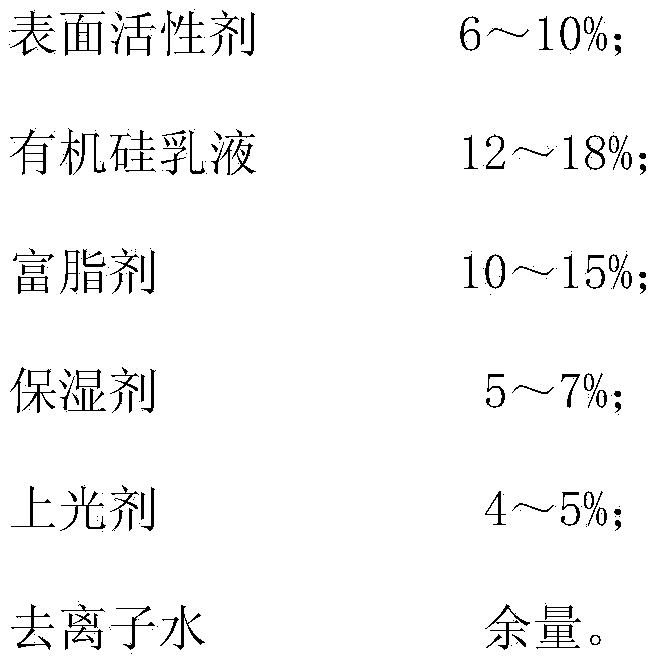

Image

Examples

Embodiment 1

[0014] Under heating, 100g of emulsifier, 150g of anionic silicone emulsion; 120g of water-soluble jojoba oil and coconut glyceride (the mass ratio of water-soluble jojoba oil and coconut glyceride is 40:60), 50g of humectant, 50g of polish containing 10% (weight) of silicon dioxide, and 450g of deionized water are mixed and stirred uniformly at 80°C, and discharged after cooling to about 45°C.

Embodiment 2

[0016] Under heating, mix 60g of emulsifier, 180g of composite ionic silicone emulsion, 110g of water-soluble jojoba oil and coconut glyceride mixture (the mass ratio of water-soluble jojoba oil to coconut glyceride is 45:55 ), 70g of humectant, 45g of glazing agent containing 10-15% (weight) of silicon dioxide, and 550g of deionized water are mixed and stirred uniformly at 80°C, cooled to about 45°C and then discharged.

Embodiment 3

[0018] Under heating, mix 80g of emulsifier, 160g of composite ionic silicone emulsion, 150g of water-soluble jojoba oil and coconut glyceride (the mass ratio of water-soluble jojoba oil to coconut glyceride is 35:65 ), 50g of humectant, 45g of glazing agent containing 10-15% (weight) of silicon dioxide, and 500g of deionized water are mixed and stirred evenly at 80°C, cooled to about 45°C and then discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com