Hexogen production wastewater treatment system and method

A technology for producing waste water and waste water, which is applied in the directions of water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high one-time investment and operation cost, general solid waste treatment, Increase processing costs and other issues to achieve the effect of promoting sustainable development, highlighting economic and social benefits, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

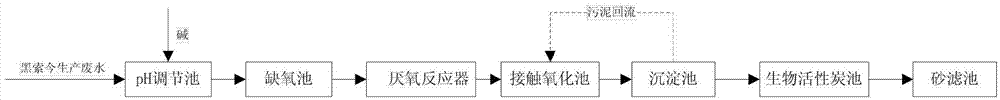

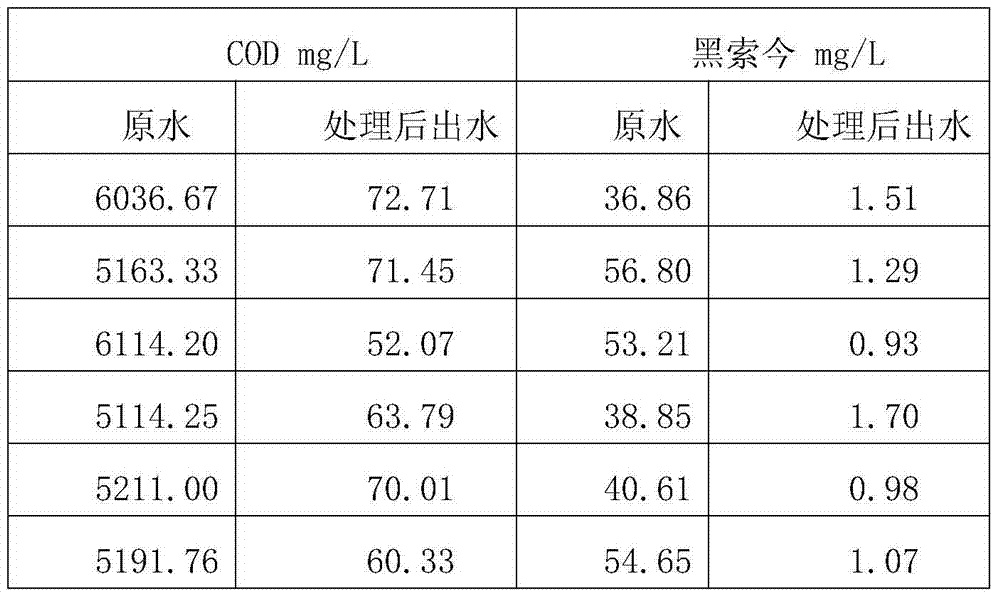

[0032] Taking the RDX production wastewater discharged from a certain factory as the treatment object, its parameters are: COD=6000±700mg / L, RDG=30~60mg / L, BOD 5 =2800~3200mg / L, pH=2.2~3.1.

[0033] Adopt device and method of the present invention to carry out compound treatment to above-mentioned Hexogen production wastewater, concrete treatment steps are as follows:

[0034] A kind of processing method of RDX production waste water of the present invention, concrete processing steps are as follows:

[0035] 1) Discharge the waste water produced by Heisuojin into the pH adjustment pool, set the pH adjustment range of the pH real-time monitoring device in the pool to 4-5, control the alkali dosing device to add lye, and adjust the pH of the waste water to 4-5 , stir while adding lye;

[0036] 2) Pump the waste water after the pH value adjustment in the first step into the anoxic pool, and carry out anoxic reaction and electrochemical reaction in the anoxic pool, and control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com