Method for preparing low-specific surface area magnesium hydroxide flame retardant by using microchannel reactor

A technology of microchannel reactor and low specific surface area, applied in the direction of magnesium hydroxide, etc., can solve the problems of amplification effect, magnesium hydroxide cannot meet the requirements of high-grade magnesium hydroxide flame retardant, long reaction time, etc., and reach the particle size The effect of narrow distribution, controllable average particle size and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

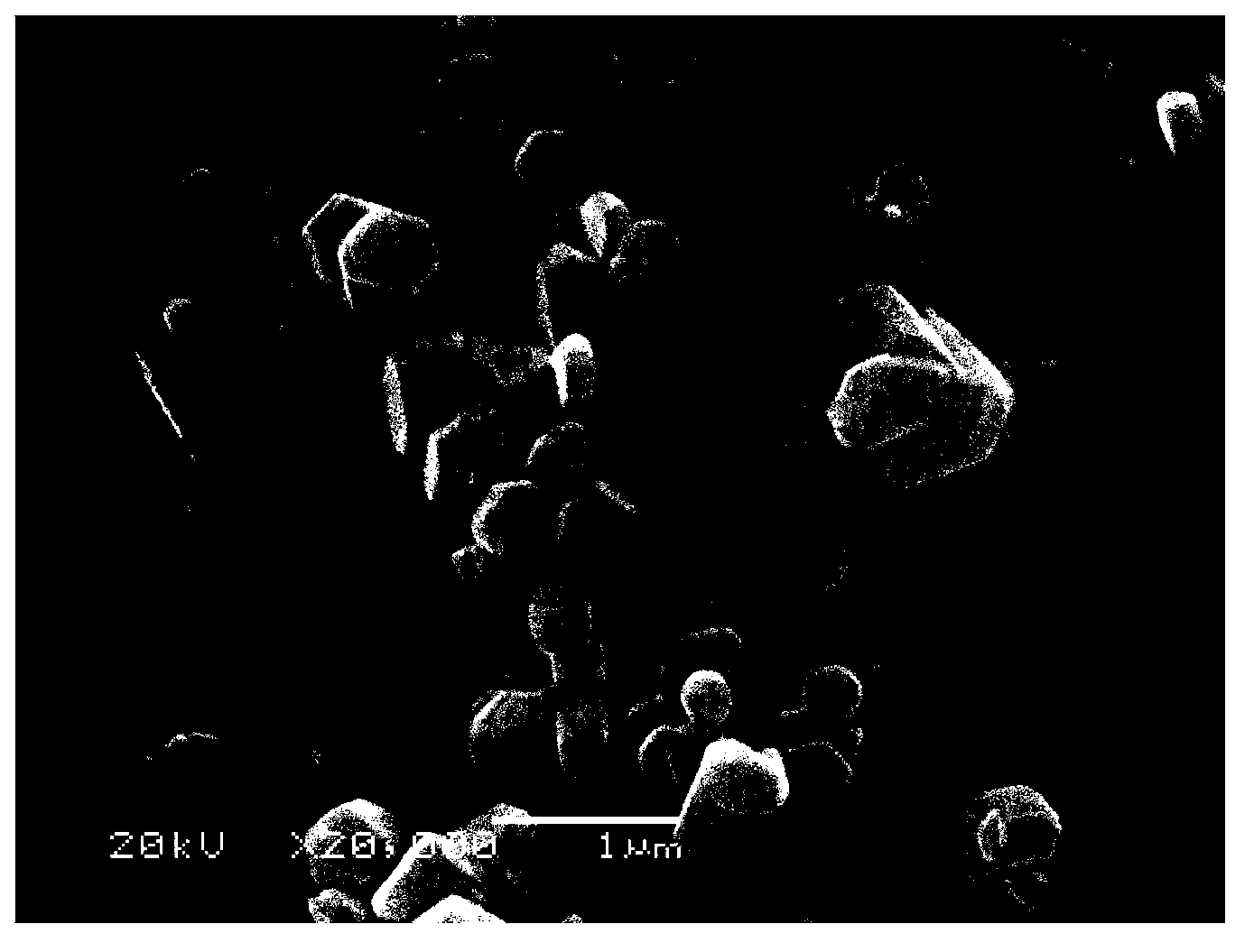

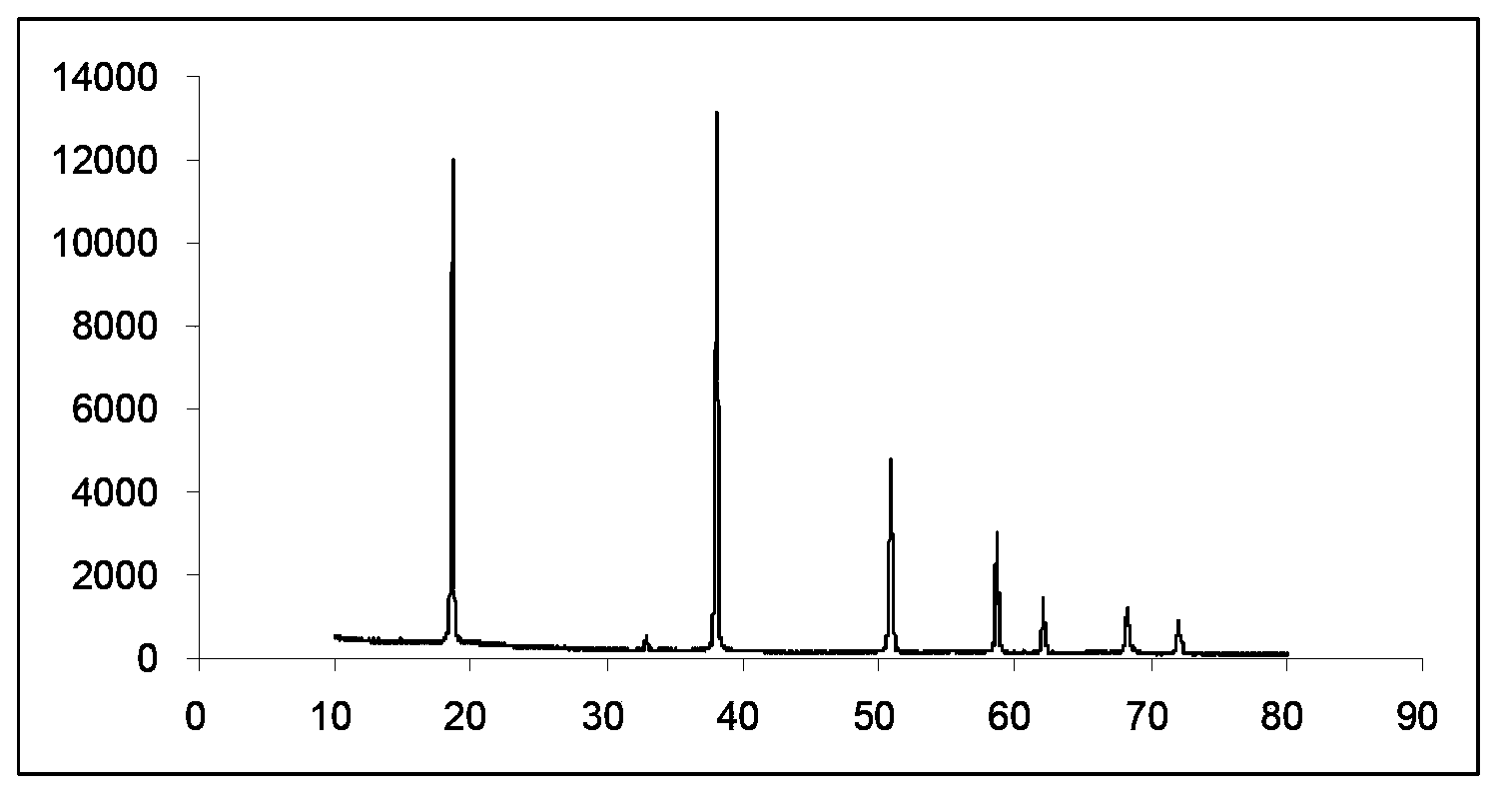

[0030] Prepare 0.5mol / L magnesium chloride solution and 1.0mol / L sodium hydroxide solution, two kinds of raw material liquids are passed into microchannel reactor continuously with advection pump respectively, carry out precipitation reaction in microchannel reactor at room temperature. Wherein the pump speed of magnesium chloride solution and sodium hydroxide solution is controlled at 200ml / min and 200ml / min respectively. The slurry at the outlet of the microchannel reactor is filtered to obtain a filter cake, and then the 2.0mol / L sodium hydroxide solution and the filter cake are mixed at a volume ratio of 2:1 to make a slurry, and the slurry is passed into a hydrothermal synthesis kettle for hydrothermal synthesis. Thermal reaction, the hydrothermal reaction temperature is 150°C, and the hydrothermal time is 6h. After the hydrothermal reaction, the product is filtered, the filtrate is recovered and recycled, and the filter cake is washed, dried and crushed to obtain an aver...

Embodiment 2

[0032] Prepare 0.5 mol / L magnesium chloride solution and 0.5 mol / L sodium hydroxide solution, respectively pass the two kinds of raw material solutions into the microchannel reactor continuously by advection pump, and carry out precipitation reaction in the microchannel reactor at room temperature. Wherein the pump speed of magnesium chloride solution and sodium hydroxide solution is controlled at 100ml / min and 200ml / min respectively. The slurry at the outlet of the microchannel reactor is filtered to obtain a filter cake, and then the 4.0mol / L sodium hydroxide solution and the filter cake are mixed at a volume ratio of 3:1 to make a slurry, and the slurry is passed into a hydrothermal synthesis kettle for hydrothermal synthesis. Thermal reaction, the hydrothermal reaction temperature is 160°C, and the hydrothermal time is 4h. After the hydrothermal reaction, the product is filtered, the filtrate is recovered and recycled, and the filter cake is washed, dried and crushed to ob...

Embodiment 3

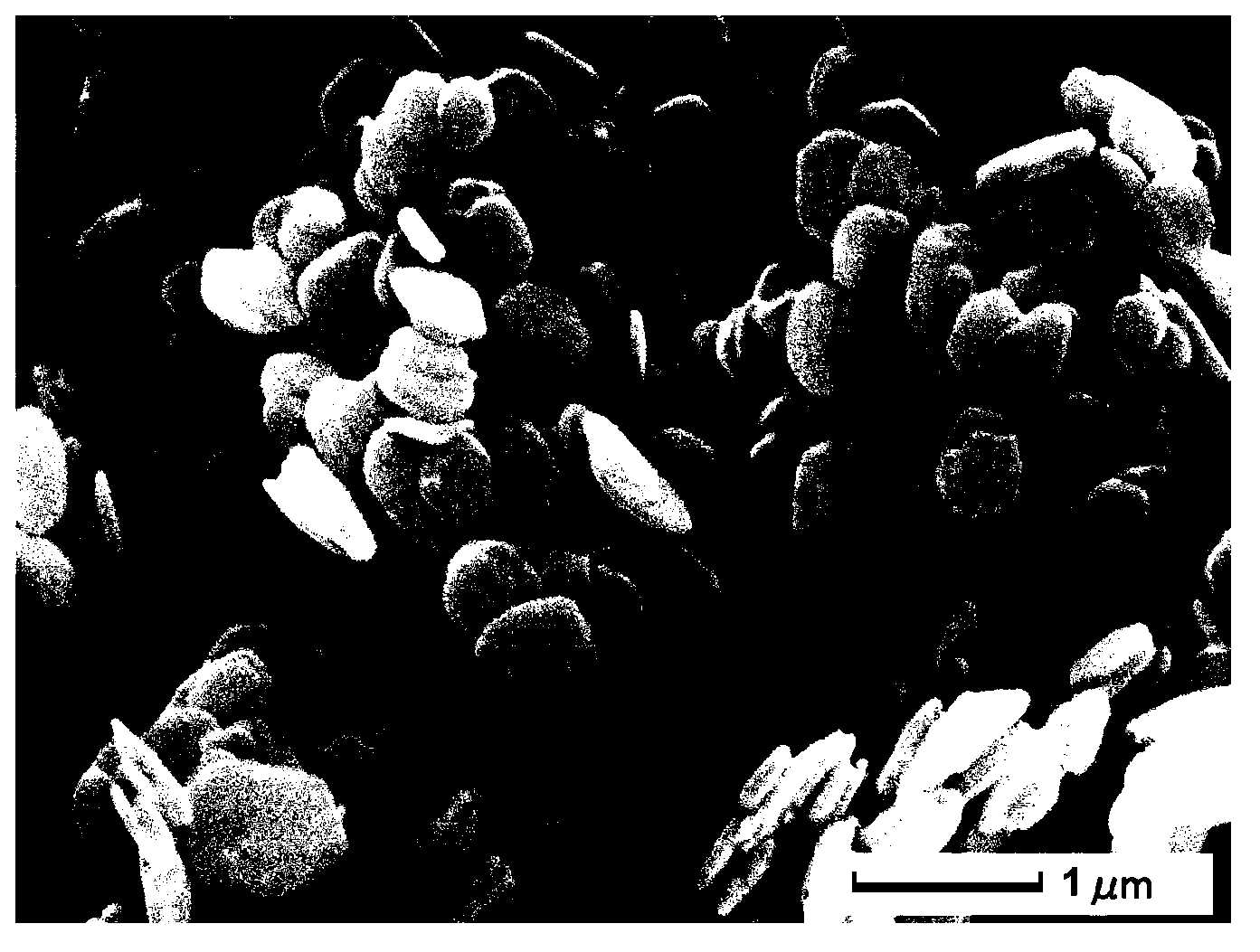

[0034] Prepare 2.0 mol / L magnesium chloride solution and 4.0 mol / L sodium hydroxide solution, respectively pass the two kinds of raw material solutions into the microchannel reactor continuously with advection pump, and carry out precipitation reaction in the microchannel reactor at room temperature. Wherein the pump speed of magnesium chloride solution and sodium hydroxide solution is controlled at 20ml / min and 20ml / min respectively. The slurry at the outlet of the microchannel reactor is filtered to obtain a filter cake, and then the 1.0mol / L sodium hydroxide solution and the filter cake are mixed at a volume ratio of 1:1 to make a slurry, and the slurry is passed into a hydrothermal synthesis kettle for hydrothermal synthesis. Thermal reaction, the hydrothermal reaction temperature is 200°C, and the hydrothermal time is 2h. After the hydrothermal reaction, the product is filtered, the filtrate is recovered and recycled, and the filter cake is washed, dried and crushed to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com