A fleece filling machine with a cutting, sealing, splitting and clamping device

A technology of sealing splitting and sealing device, applied in the field of fleece filling machine, can solve the problems that affect the sealing quality, the pieces to be sealed are easy to bulge, wrinkle, etc., achieve good leveling effect, ensure quality, and increase pressing force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

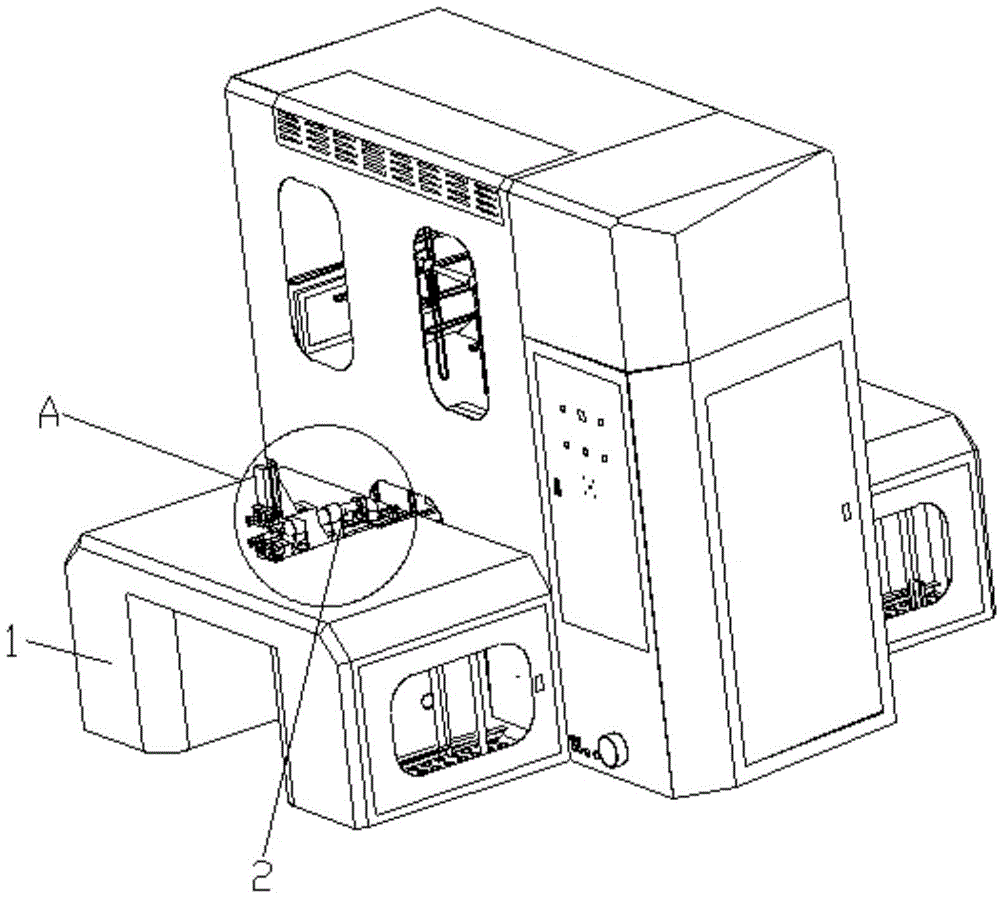

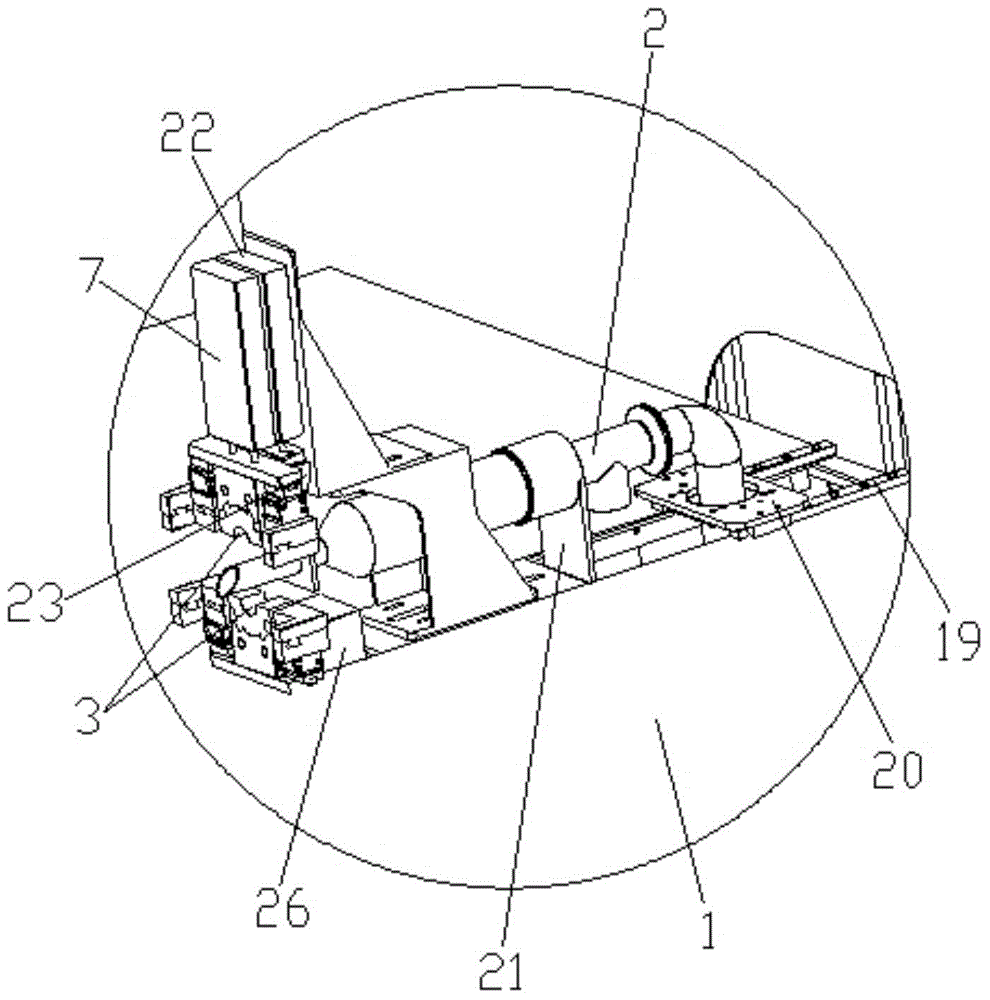

[0024] as attached Figure 1-5 As shown, the sealing device is located on the inside of the piece sealing splitting and clamping device.

[0025]A new type of full-automatic down filling machine according to the present invention, in the initial state, the telescopic rods of the first cylinder, the second cylinder, the third cylinder and the fourth cylinder shrink, and the upper pressing block and the ultrasonic sealer, the upper pressing The device is separated from the lower pressing device, and the first pressing block, the clamping block and the second pressing block in the upper pressing device are spliced together sequentially, and the lower pressing device is in the same structural state as the upper pressing device. When starting to use, the operator first puts the cut piece on the front end of the down filling tube, opens the first cylinder and the second cylinder, and the telescopic rods of the first cylinder and the second cylinder drive the upper pressing device ...

Embodiment 2

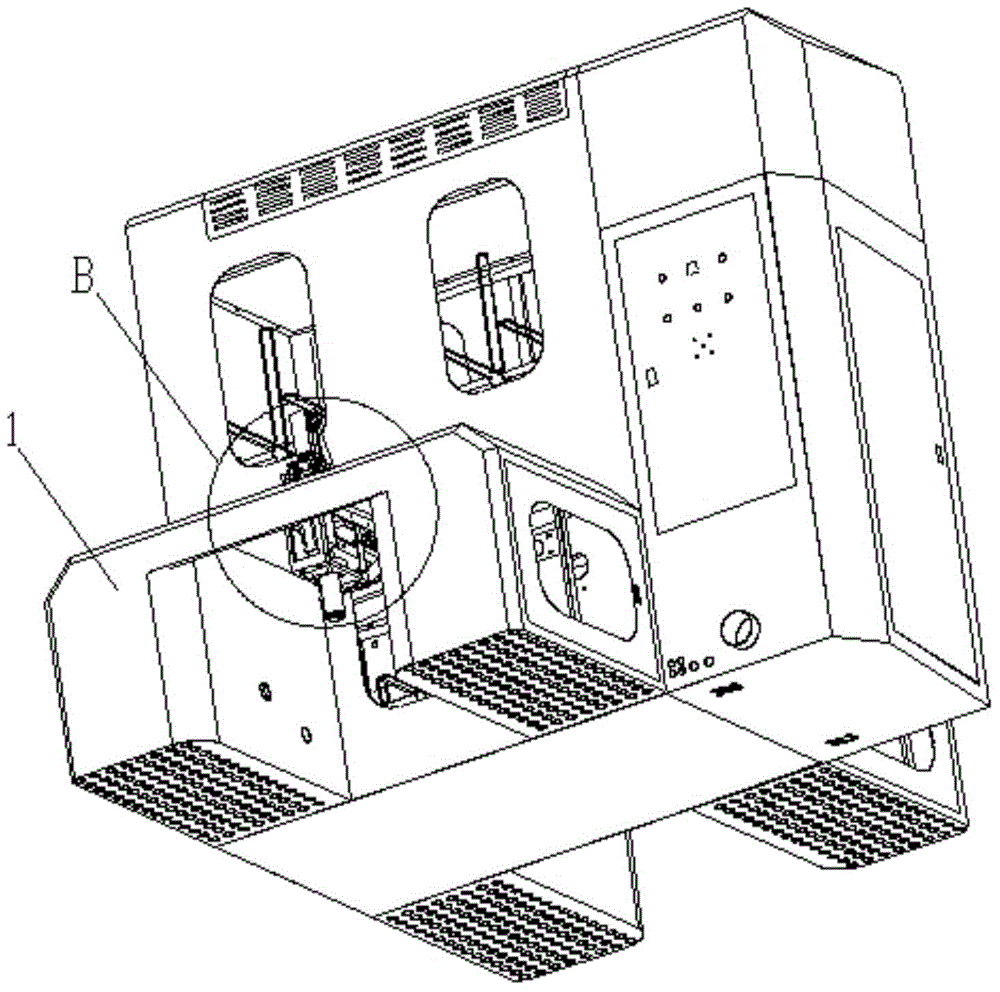

[0027] The sealing device is located on the outside of the piece sealing, separating, closing and clamping device, and the telescopic device controls the outward movement of the sealing device. The other principles are the same as those in Embodiment 1.

[0028] The above-mentioned down filling machine provided with the piece sealing, separating and clamping device, since rubber pads are provided under the first pressing block and the second pressing block and under the clamping block in the upper pressing device, this increases the The friction force of the lower surface of the first pressing block, the second pressing block and the clamping block makes the flattening effect of the cut piece to be sealed better; the lower pressing device has the same structure as the upper pressing device, and no longer stated.

[0029] In the above-mentioned cashmere filling machine equipped with a piece sealing, separating, closing and clamping device, the first pressing block and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com