A belt conveyor

A technology for belt conveyors and storage belts, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high energy consumption and safety of belt conveyors, achieve reduced maintenance requirements, changeable structures, and improve The effect of system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

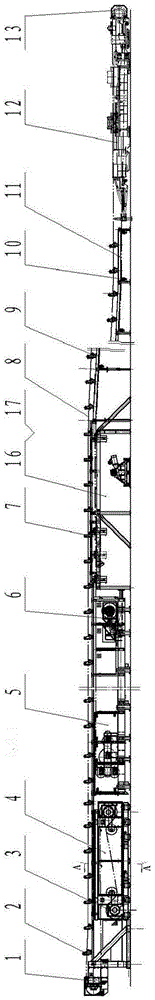

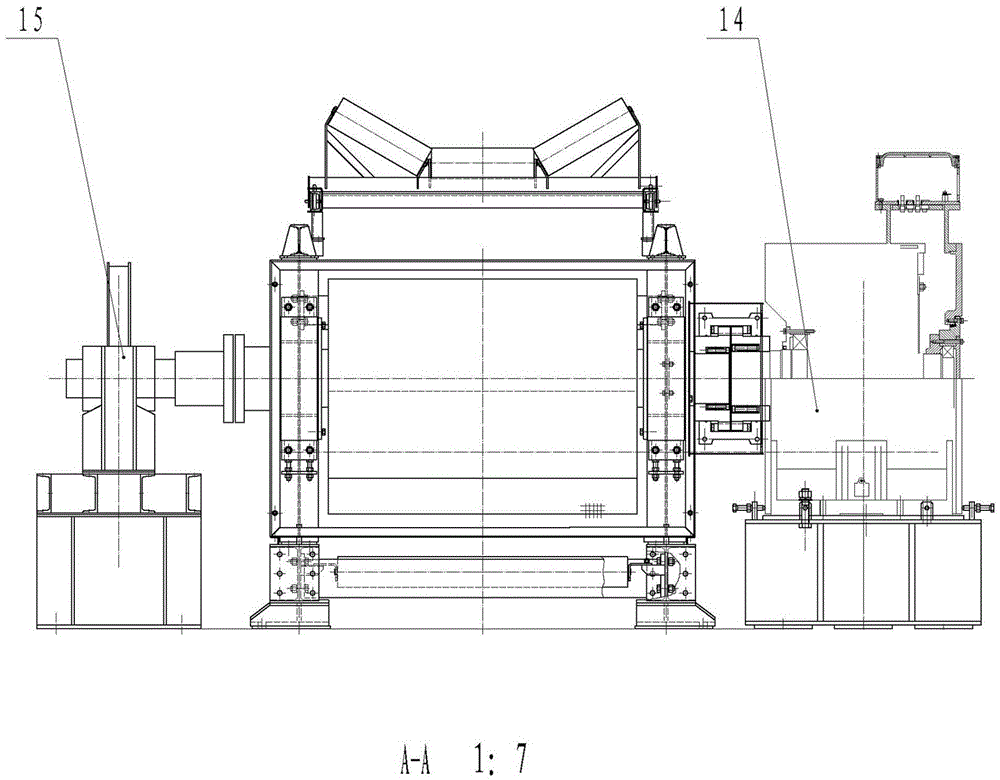

[0021] The present invention is described in detail below in conjunction with accompanying drawing: as figure 1 , 2 Shown is a structural schematic diagram of the present invention, a belt conveyor, including a fuselage portion 11, an unloading portion 1, a head portion 4, a storage belt tensioning portion 5, a retractable tape device 7, a driving device, and a transitional anti-running mechanism. Offset front idler group 2, tape 8, self-moving machine tail 12, belt protection and belt conveyor control system 16, video monitoring system 17; unloading part 1 is connected with machine head 4; machine head includes transition anti-running Offset front idler group 2, driving drum 3, permanent magnet motor driving device 14, disc brake 15;

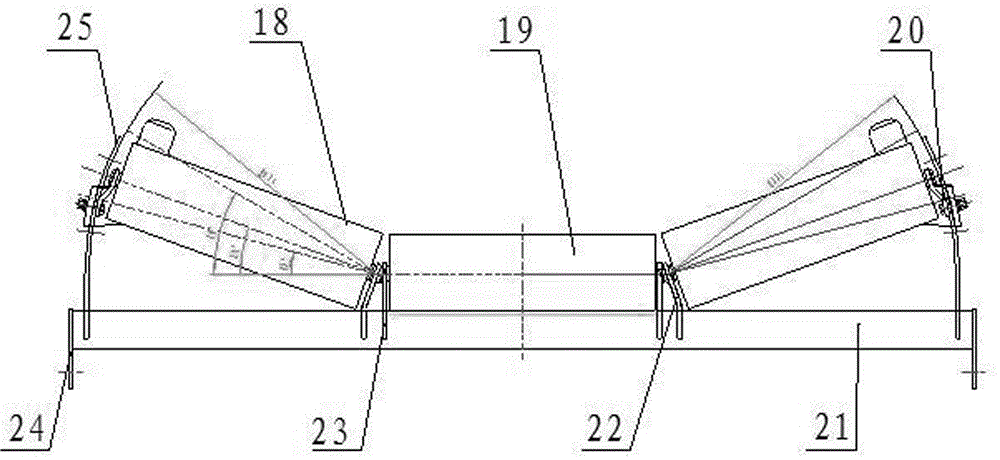

[0022] The storage belt tensioning part 5 includes a permanent magnet frequency conversion tensioning device 6; the retractable tape device 7 is connected behind the storage belt tensioning part 5; the fuselage part 11 includes a trough-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com