Pneumatic rotary feeding device

A feeding device and pneumatic technology, applied in the field of pneumatic rotary feeding device, can solve problems such as damage to the motor and difficulty of swinging the pendulum rod quickly and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

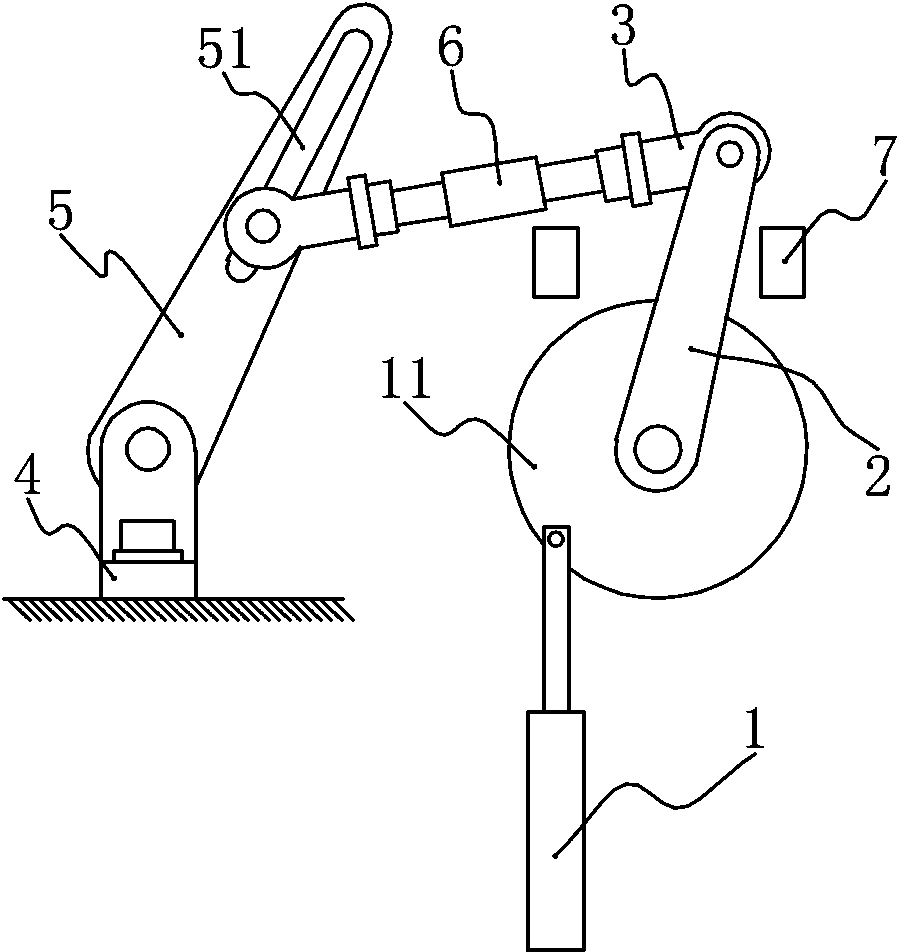

[0012] Such as figure 1 As shown, the pneumatic rotary feeding device of the present invention includes a vertical support, on which a cylinder 1 is fixed, and the piston rod of the cylinder 1 is eccentrically hinged on the rotary disk 11, and the rotating shaft of the rotary disk 11 is the same as Axle fixed a rotating rod 2. The free end of the rotating rod 2 is fixedly connected with a connecting rod 3, and the connecting rod 3 is divided into a hinged end and a sliding end. Also be provided with a fixed seat 4 on the support, on the fixed seat is hinged with a fork 5, the middle section of the fork 5 is provided with a chute 51, and the sliding end of the connecting rod 3 is fixed in the chute 51. In addition, the middle section of the connecting rod 3 is provided with a loose bolt 6, which is a through threaded pipe, and the threads at both ends of the threaded pipe are in the opposite direction; the connecting rod 3 includes two threaded rods, and the two threaded rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com