Lift roller based hull block turning equipment during ship construction

A construction process and rolling wheel technology, applied in ship construction, ship parts, ships, etc., can solve the problems of high construction and maintenance costs of large cranes, achieve the effects of perfect and beautiful shipbuilding, reduce secondary transshipment, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention realizes the turnover function of the ship section without lifting lugs and without a crane, and provides a turnover system and implementation method of the ship section. The present invention will be further described below in conjunction with the accompanying drawings.

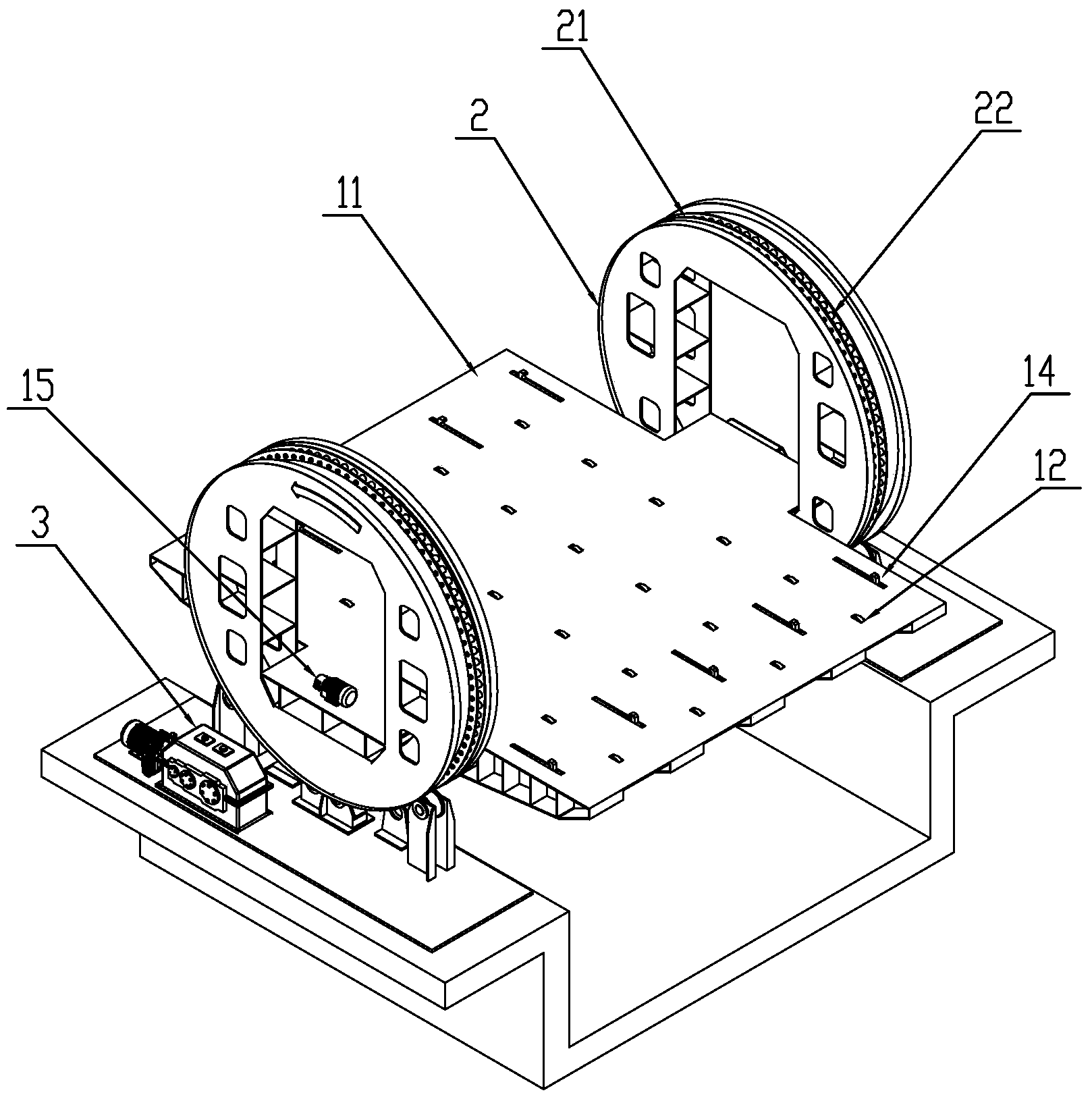

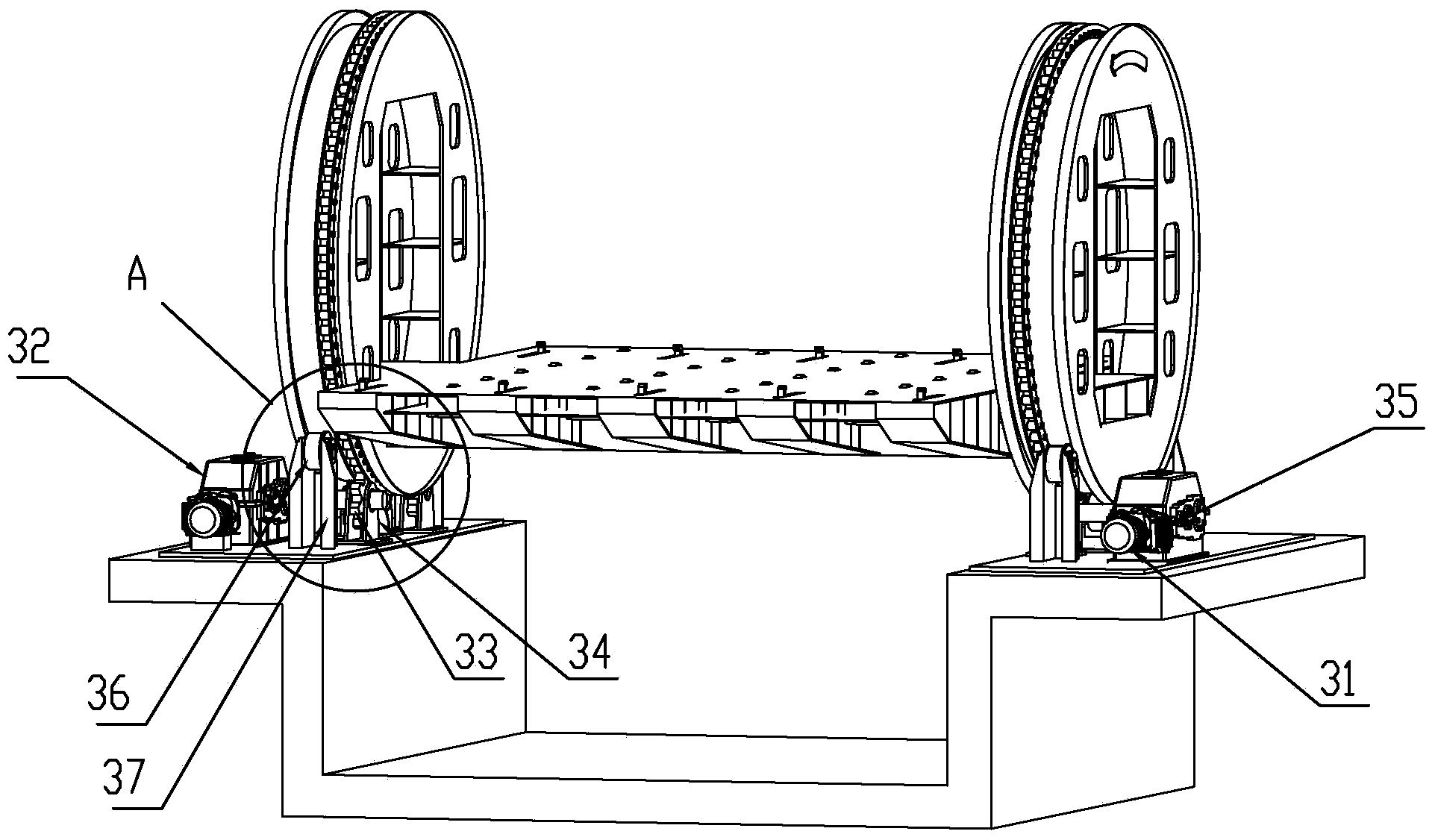

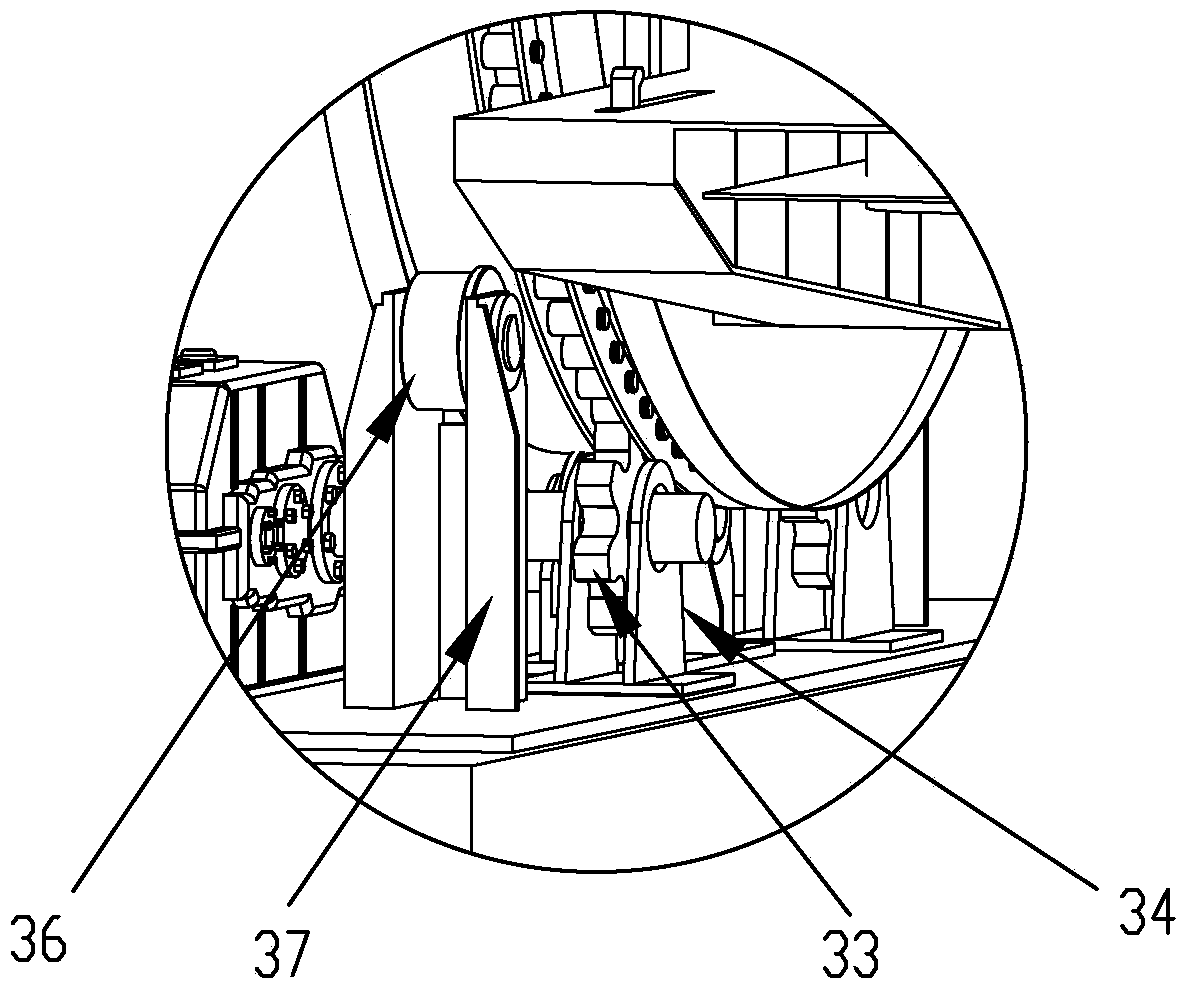

[0043] Such as figure 1 and 2 , combined with Figure 6 and 7 The turnover system of hull segments in the ship building process of the present invention is shown, including turnover equipment and mobile lift car equipment. Among them, such as figure 1 and 2 As shown, the turning device includes a turntable 11 whose two sides are respectively fixed on the turning circle 21 for turning over; the turntable 11 includes an electromagnet adsorption component and a plane that is attached to the hull section. Such as image 3 As shown, driven round pins 22 are arranged at intervals on the outer circumference of each said turning circle 21, and cooperate with the outer drive gear 33 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com