Towing devices for unpowered vehicles in the production process

A traction device and production process technology, applied in tractors, motor vehicles, transportation and packaging, etc., to achieve reliable vehicle traction and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

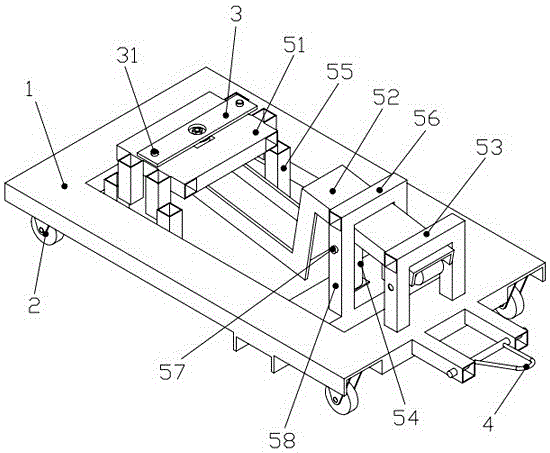

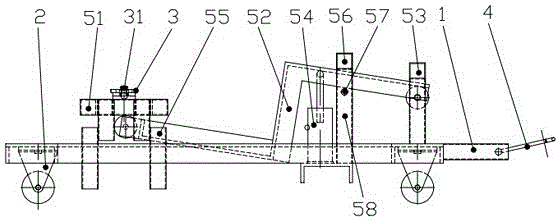

[0017] see figure 1 and figure 2 , a traction device for unpowered vehicles in the production process, including a chassis 1, four universal wheel assemblies 2 arranged under the chassis 1, a lifting device arranged on the chassis 1, and a rear connection pivotally connected to the lifting device Mechanism and the front connection mechanism 4 that is arranged on the chassis 1 front end.

[0018] This lifting device comprises four vertical position-limiting guide rails 55 fixed on the upper rear end of the chassis 1, and a lifting platform 51 that slides up and down along the position-limiting guide rails 55 is provided in the position-limiting guide rails 55, and a front end on the top of the chassis 1 is fixed Bracket 53 is pivotally connected with a push rod 52 on the support 53. Under the push rod 52, one end is fixed on the chassis 1 and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com