Positive pressure ventilation system for diesel locomotive power room

A technology of positive pressure ventilation and internal combustion locomotives, applied to locomotives and other directions, can solve the problems of large fan volume, affecting the cleanliness of the power room, and occupying a large space, and achieve the effect of clear cooling goals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

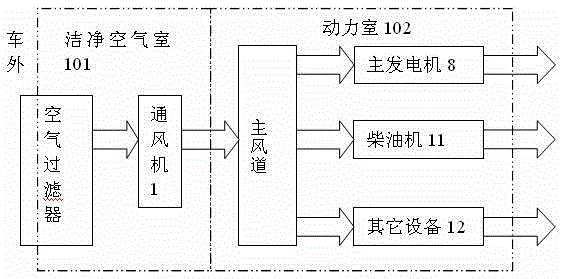

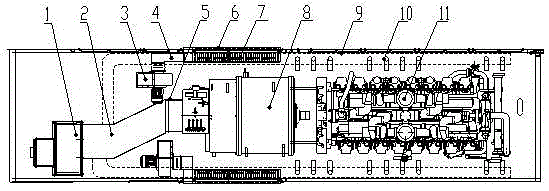

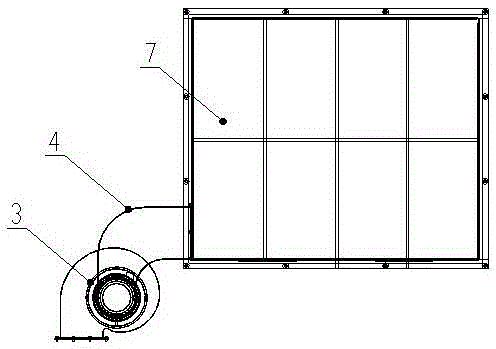

[0028] Such as figure 1 , figure 2 As shown, a positive pressure ventilation system for a diesel locomotive power room includes a sealed clean air room 101 and a power room 102. The clean air room 101 is provided with a ventilator 1, and the power room 102 is provided with a main generator 8, a diesel engine 11 and The inherent equipment 12, the outlet end of the air filter is connected with the ventilator 1, and the ventilator 1 is connected with the main generator 8, the diesel engine 11 and the inherent equipment 12 respectively through the main air duct 2; The air outlet pipe 10 of the power chamber 102 is connected to the air duct 9 that communicates with it.

[0029] The ventilator is placed in a closed clean air room, and the outside air can only enter the clean air room through the air filter. When the fan is working, the outside air enters the clean air room after passing through the air filter. After being pressurized by the fan, the air with a certain pressure an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com