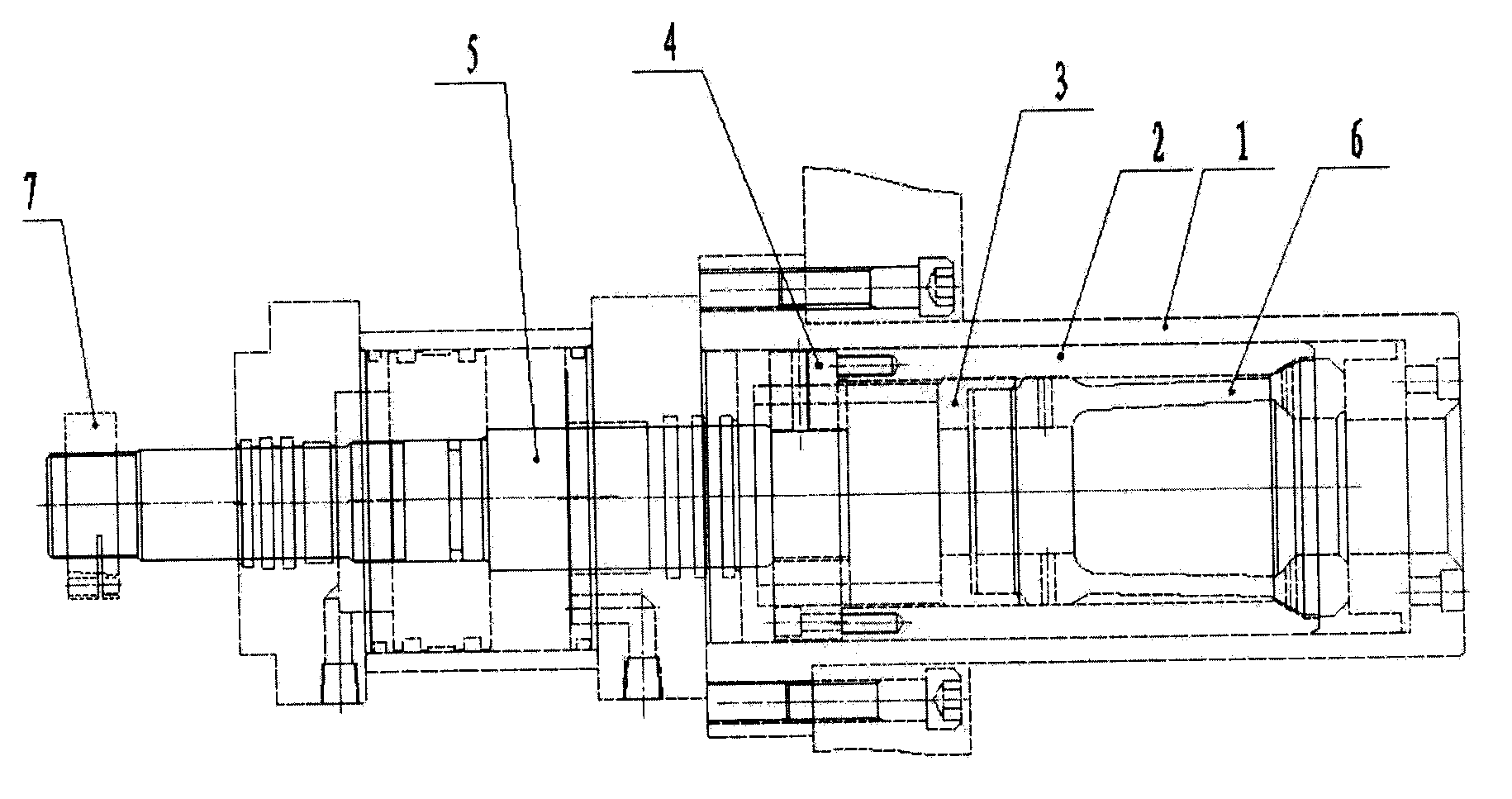

Die-assembling mechanism in hollow plastic molding machine

A mold clamping mechanism and molding machine technology, which is applied in the field of blow molding machines, can solve the problems of increasing the workload of technical staff and different stroke positions of multiple piston rods, and achieve the effects of simple structure, long service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] As shown in the accompanying drawings, the piston rod in the clamping cylinder is made into a double-headed piston rod 10, one end is connected with the lock buckle 11, and the other end is equipped with an adjusting nut 12 and a lock nut 13 that can adjust the stroke position of the piston rod, and at the same time Add locking screws; according to the thickness of the mold 21 and mold 22 in the mold opening and closing mechanism diagram, the position of the adjusting nut 12 can be adjusted arbitrarily to ensure the correct position of the lock. At the same time, the stroke of the piston rod of the mold locking cylinder can be added or subtracted arbitrarily. , and install a detection device to shorten the travel time of the clamping cylinder; this design can reduce the workload and operating experience of technical staff, the pressure and flow of hydraulic oil entering the clamping cylinder can be adjusted arbitrarily, and the temperature of the hydraulic oil will Chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com