Method for manufacturing novel, energy-saving and environmental-friendly bicycle pipe support components through bamboo skin coiled materials

A kind of bamboo skin coil, energy saving and environmental protection technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

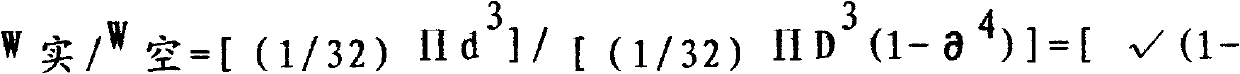

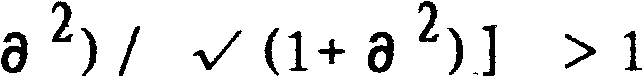

[0057] According to the shape and specification of the lower tube 6 and the upper tube 12 of the bicycle, the bamboo skin coil is used; The shape and specifications of the head tube 8, the vertical rod 9, the grip 10, the stem 11, and the vertical tube 13 are made of bamboo skin coils (according to the actual application needs, a bamboo sheet can also be used), of which the rear fork 3 With the rear seat fork 2, the joint of the rear lower fork 4 utilizes a tenon-and-mortise structure, the connection of the rear seat fork 2 and the riser 13 also utilizes a tenon-and-mortise structure, and the rear lower fork 4 and the bottom bracket 5 also utilize a tenon-and-mortise structure to connect, The other end of the stand pipe 13, the lower pipe 6 and the five-way 5 are also connected with a tenon-and-mortise structure, and the joint of the stand pipe 13 and the upper pipe 12 also has tenon-and-mortise; the upper pipe 12 and the lower pipe 6 are combined with the head pipe 8 respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com