Special equipment used for automatically welding flat-top chain accessory for conveying

A technology of automatic welding and special equipment, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as affecting the firmness of welding points, affecting the stability of chain conveying, and difficult to ensure the position accuracy of guide plates and chains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below according to the drawings and embodiments.

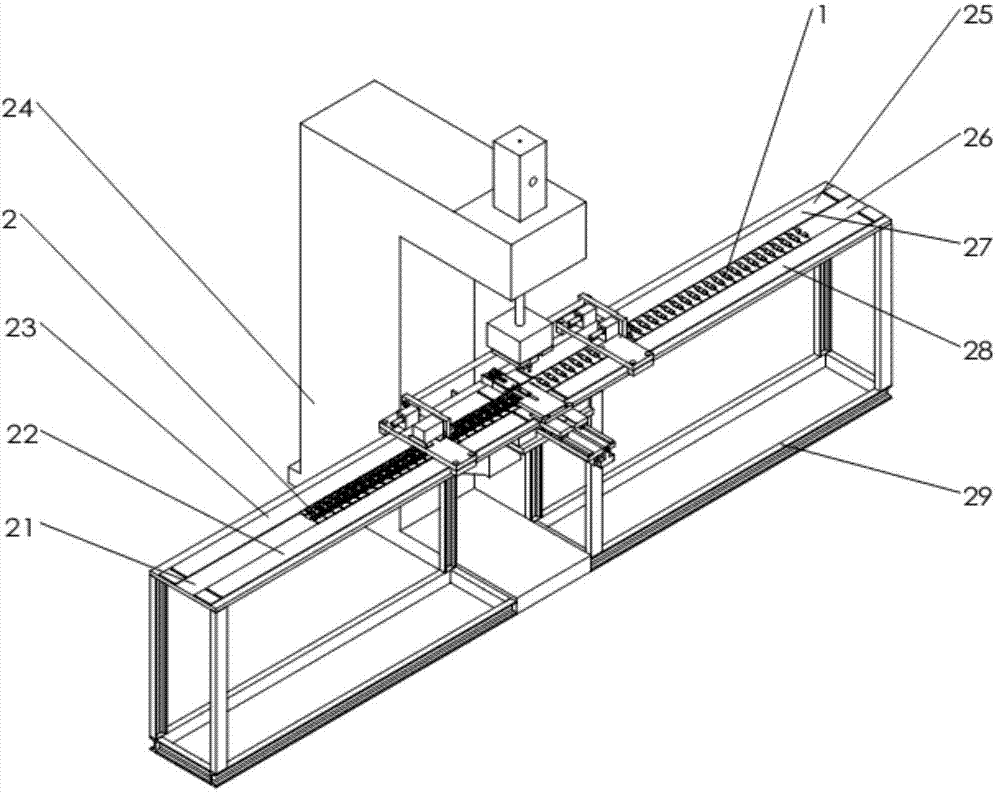

[0025] refer to Figure 2-Figure 5 , The present invention, the special equipment for the automatic welding of flat-top chain accessories for conveying, includes a frame, a projection welding machine, a chain plate moving device, a feeding device, and a welding device.

[0026] Such as figure 2 Shown: the projection welding machine 24 is set in the center, the left and right sides of the projection welding machine 24 are frame 29, the frame 29 adopts channel steel welding, and the bottom surface is flush with the projection welding machine 24 base. The plane on frame 29 adopts screw to fix left plate 21 and right plate 26, adopts screw to fix left front guide plate 22, right front guide plate 28 and left rear guide plate 23, right rear guide plate 25 on left plate 21, right plate 26, The width of the chain moving notch formed between the front and rear guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com