Stabilizer bar heating device with three-direction stepping conveying function

A heating device and step-by-step conveying technology, applied in operating devices, forging/pressing/hammer devices, metal processing equipment, etc., to achieve uniform circumferential temperature and axial temperature distribution, easy control of heating quality, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

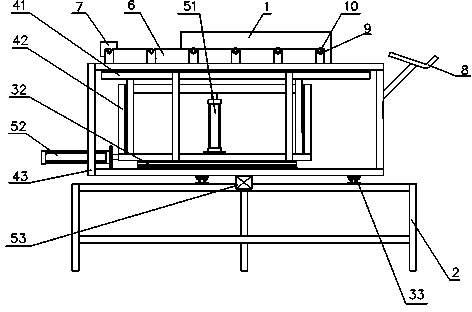

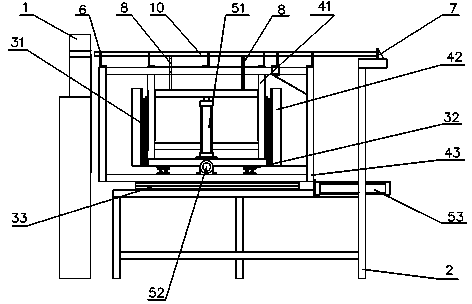

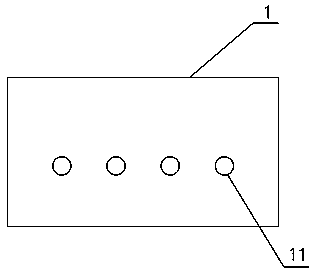

[0026] figure 1 and figure 2 Shown is a three-direction step-by-step conveying heating device for stabilizer rods of the present invention, which includes a fixed support 2 and three supports, which are respectively a first support 41, a second support 42 and a third support 43, wherein The first support 41 and the second support 42 are connected by the upper and lower axis guide rails 31, the second support 42 and the third support 43 are connected by the left and right axis guide rails 32, the third support 43 is connected with the fixed support 2 by the front and rear axis guide rails 33, the first The bracket 41 is arranged on the innermost layer, the third bracket 43 is arranged on the outermost layer, the second bracket 42 is arranged in the middle of the first bracket 41 and the third bracket 43, the upper and lower axis guide rails 31 are arranged along the Z-axis direction, and the left and right axis guide rails 32 are arranged along the The Y-axis direction is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com