Novel roller

A roll, a new type of technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of waste, poor strength, easy to break, etc., and achieve the effect of saving production cost and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

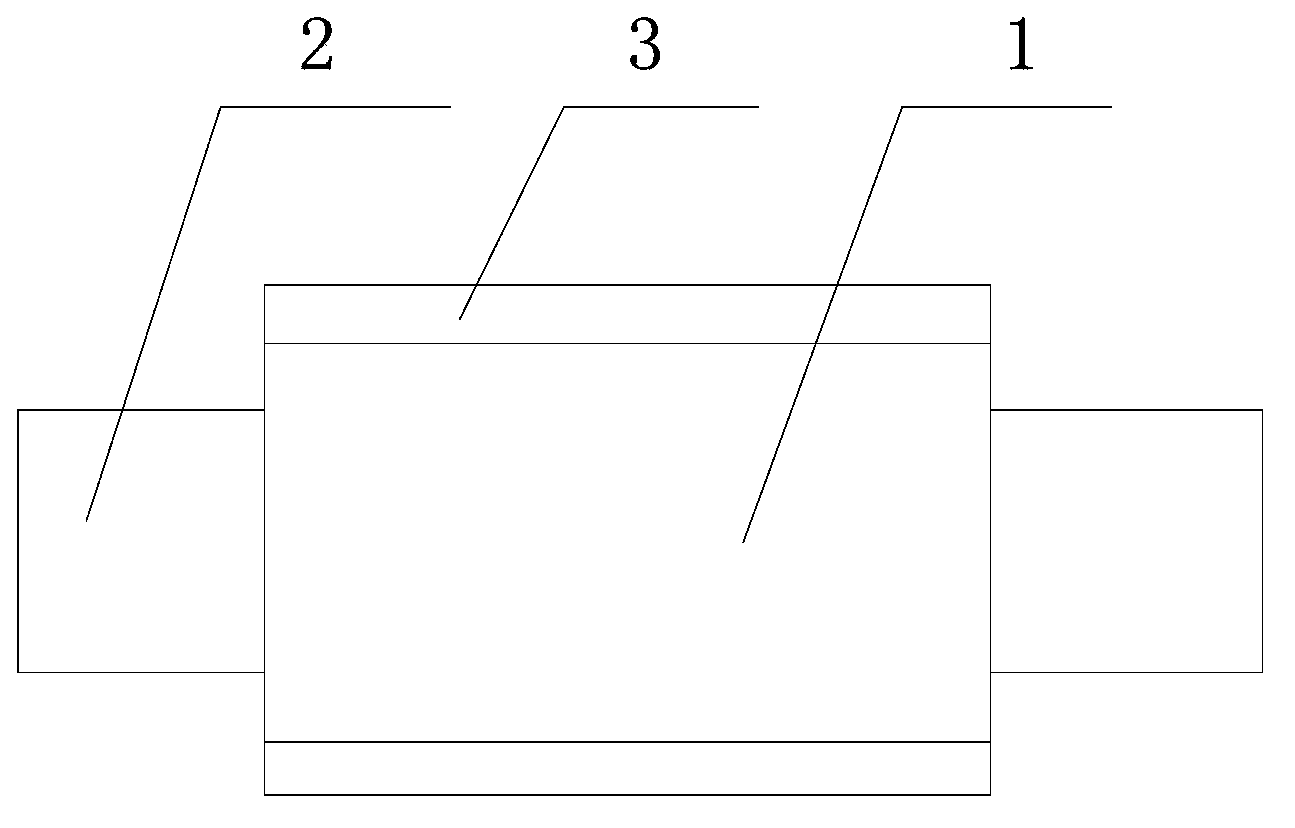

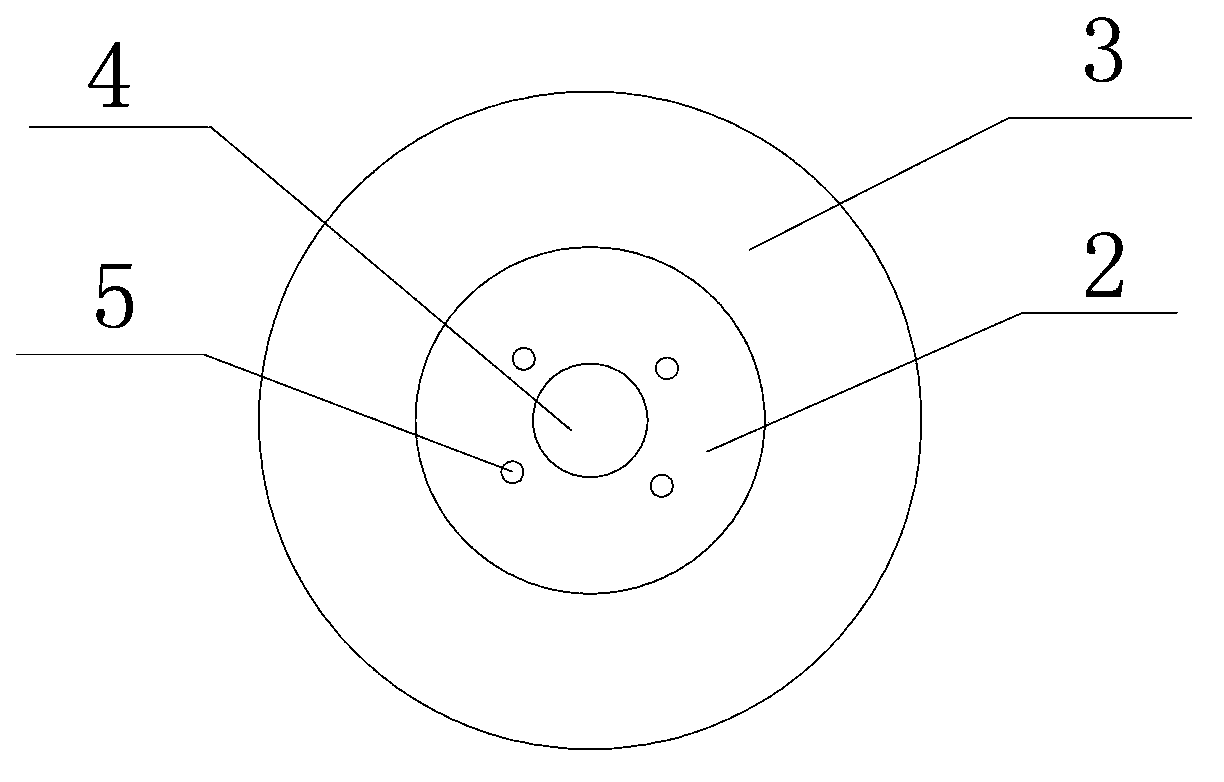

[0011] See figure 1 and figure 2 As shown, a new type of roll has a roll core 1 and a roll neck 2 connected to the roll core 1. The roll body 3 is sleeved on the surface of the roll core 1, and the center of the roll neck 2 is provided with a thread center Holes 4, at least two pin holes 5 are provided around the threaded center hole 4 on the roll neck 2. See figure 2 As shown, there are four pin holes 5 .

[0012] The specific embodiments described above have further described the purpose, technical solutions and beneficial effects of the present invention in detail. It should be understood that the above descriptions are only specific embodiments of the present invention and are not intended to limit the present invention. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com