Composite bracket insulator for metros

An insulator and wrist arm technology, applied in the field of composite electrical materials, can solve the problems of difficult to control the processing process, low mechanical strength, easy to break, etc., and achieve the effects of good mechanical strength, increased creepage distance, and good pollution resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Now in conjunction with accompanying drawing, the present invention is further described.

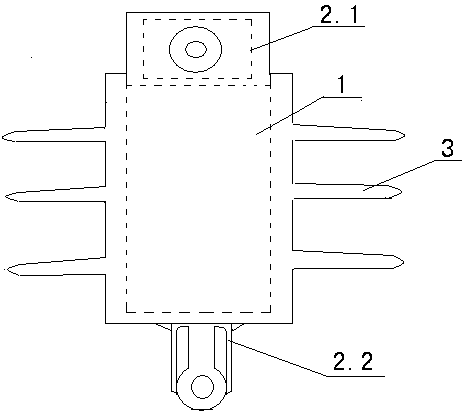

[0011] Such as figure 1 As shown, a composite arm insulator for subway, the insulator is a whole, it includes a solid rod 1 in the middle, connecting steel caps at both ends, and a large umbrella skirt 3, wherein the solid rod 1 is crimped with the steel cap, and the solid rod 1 is crimped with the steel cap. The outside of the rod 1 is wrapped with silicon rubber to form three large umbrella skirts 3 . The total height of the insulator is 343mm, the diameter of the solid rod 1 is 80mm, the outer diameter of the steel caps at both ends is 92mm, the inner diameter of the steel cap is 80mm, and the diameter of the large umbrella group 3 is 200mm.

[0012] The steel cap is divided into the upper end connection steel cap 2.1 and the lower end connection steel cap 2.2, wherein the upper end connection steel cap 2.1 is divided into two sections of structure, and the cylindrical hollow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com