Coal spontaneous combustion high-temperature program heating device and testing method using same

A temperature-programmed, coal spontaneous combustion technology, applied in measuring devices, furnace control devices, material separation, etc., can solve the problems of inability to test high-temperature stage testing, and achieve the effect of simple operation and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

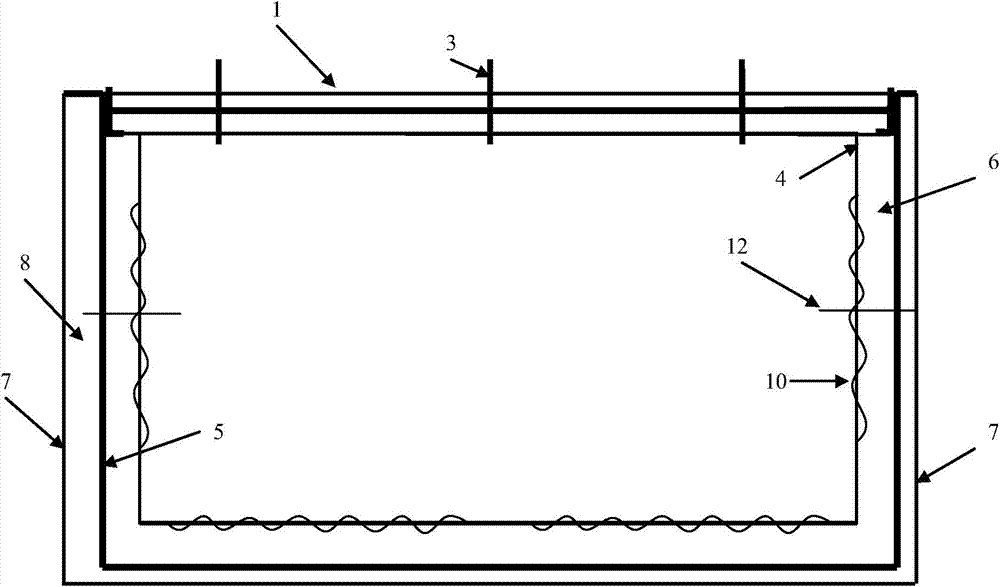

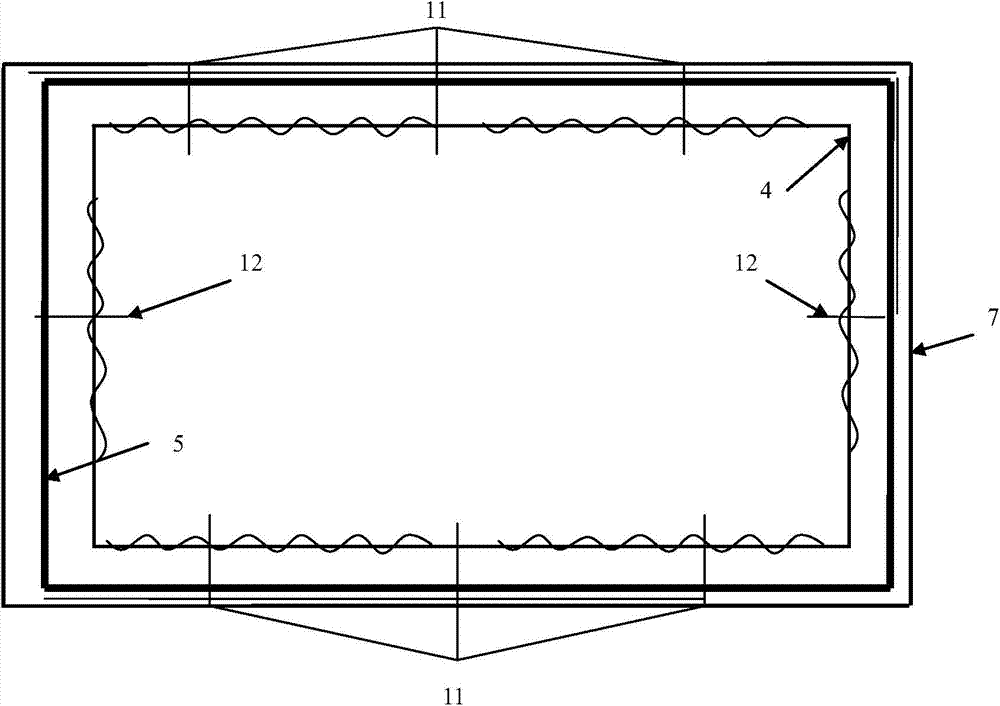

[0044]Set 6 first through holes with a diameter of 30mm in the furnace cover, and adopt a threaded structure. The lower end of the outlet pipe is a smooth straight cylinder, and the furnace is a ceramic fiber furnace. The size of the furnace is 650mm long × 450mm wide × 400mm high. The appearance size is: length 950mm×width 750mm×height 800mm, and the height of the bracket is 200mm.

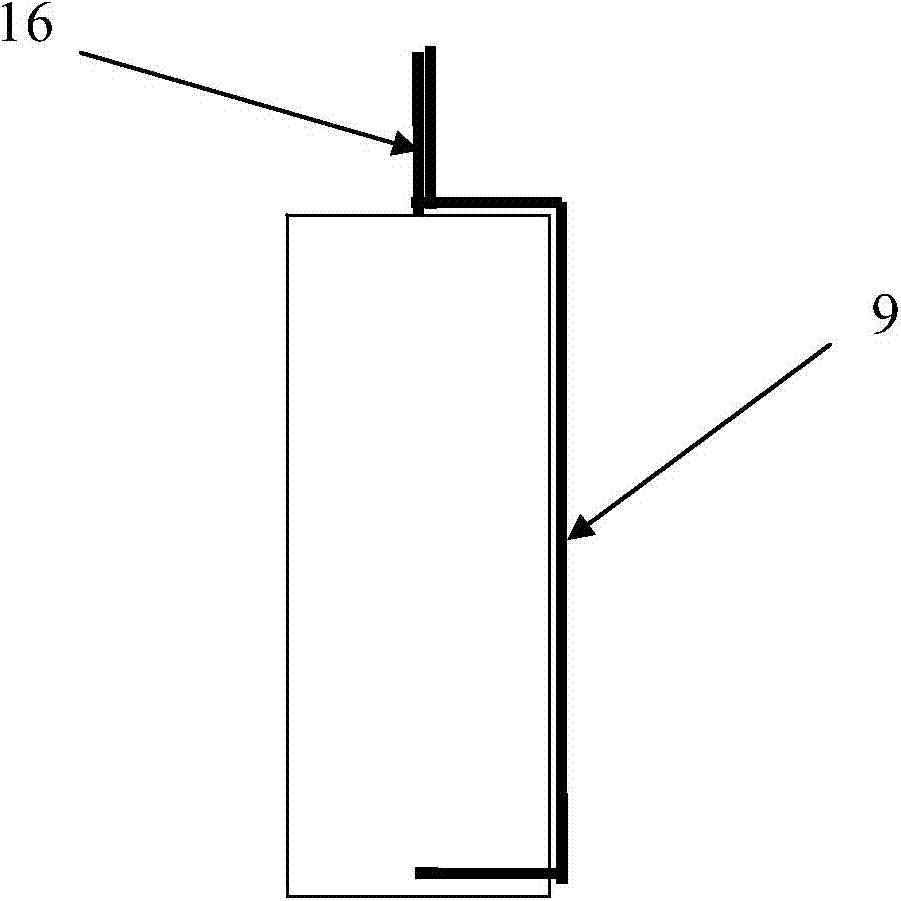

[0045] There are 6 tank bodies, which are cylindrical in shape and made of high temperature resistant carbon silicon material. There is a tank cover on the upper part of the tank body, and the tank cover and the tank body can be fixed into a closed space with nuts. The air inlet pipe is installed on the bottom of the side of the tank, and the air outlet pipe is installed on the sealing cover. The air inlet pipe and the air outlet pipe of each tank can extend to the outside of the furnace through the first through hole on the furnace cover, so as to prepare for gas collection and flow into the tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com