Heating oil tank with interlayer

A technology of oil pool and interlayer, which is applied in the direction of protecting pipelines, heat exchange equipment, and heat preservation through heat insulation, which can solve the problems of easy burns of employees and serious heat loss, etc., and achieve shortened oiling time, reduced oil fume, and reduced energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

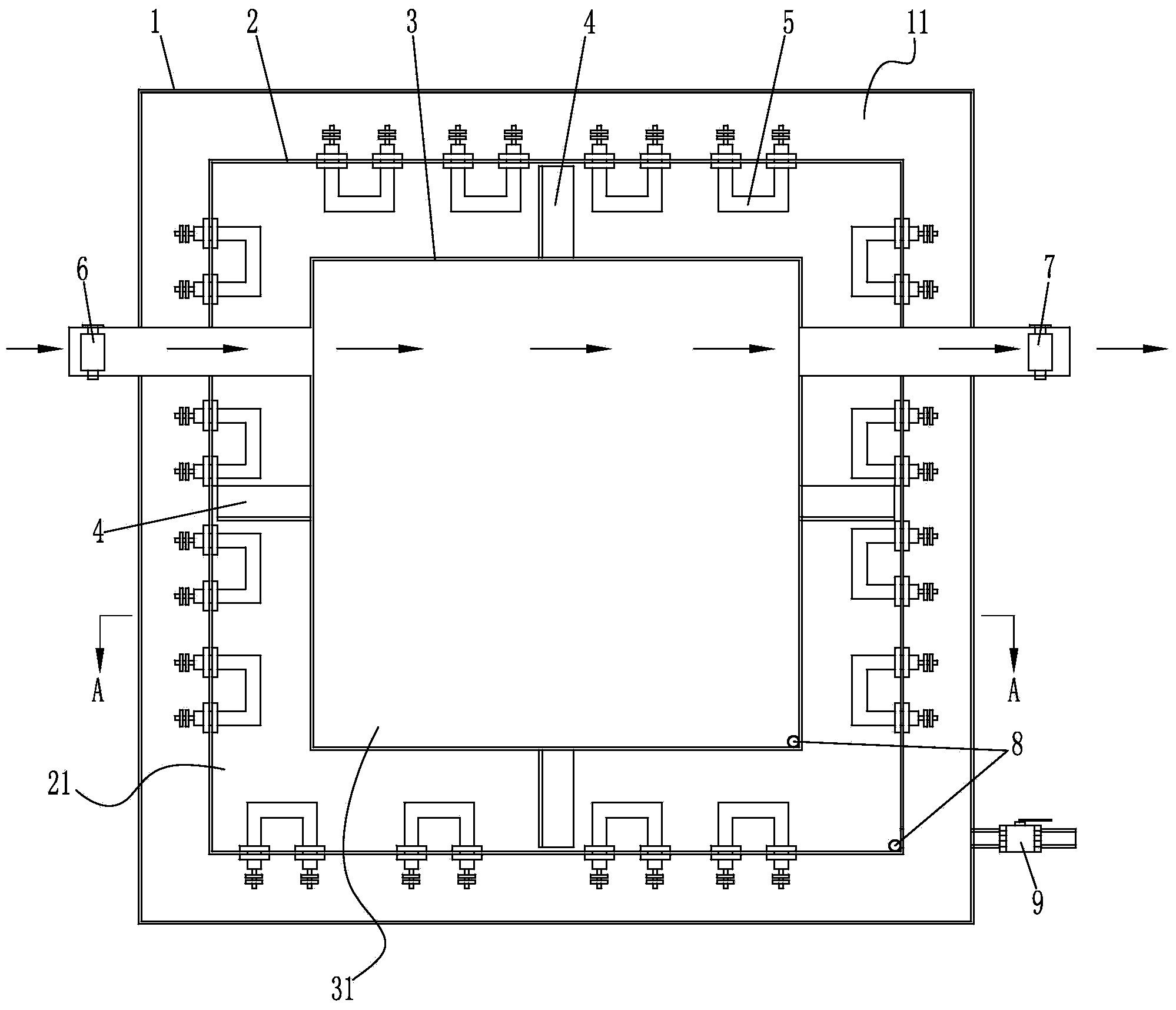

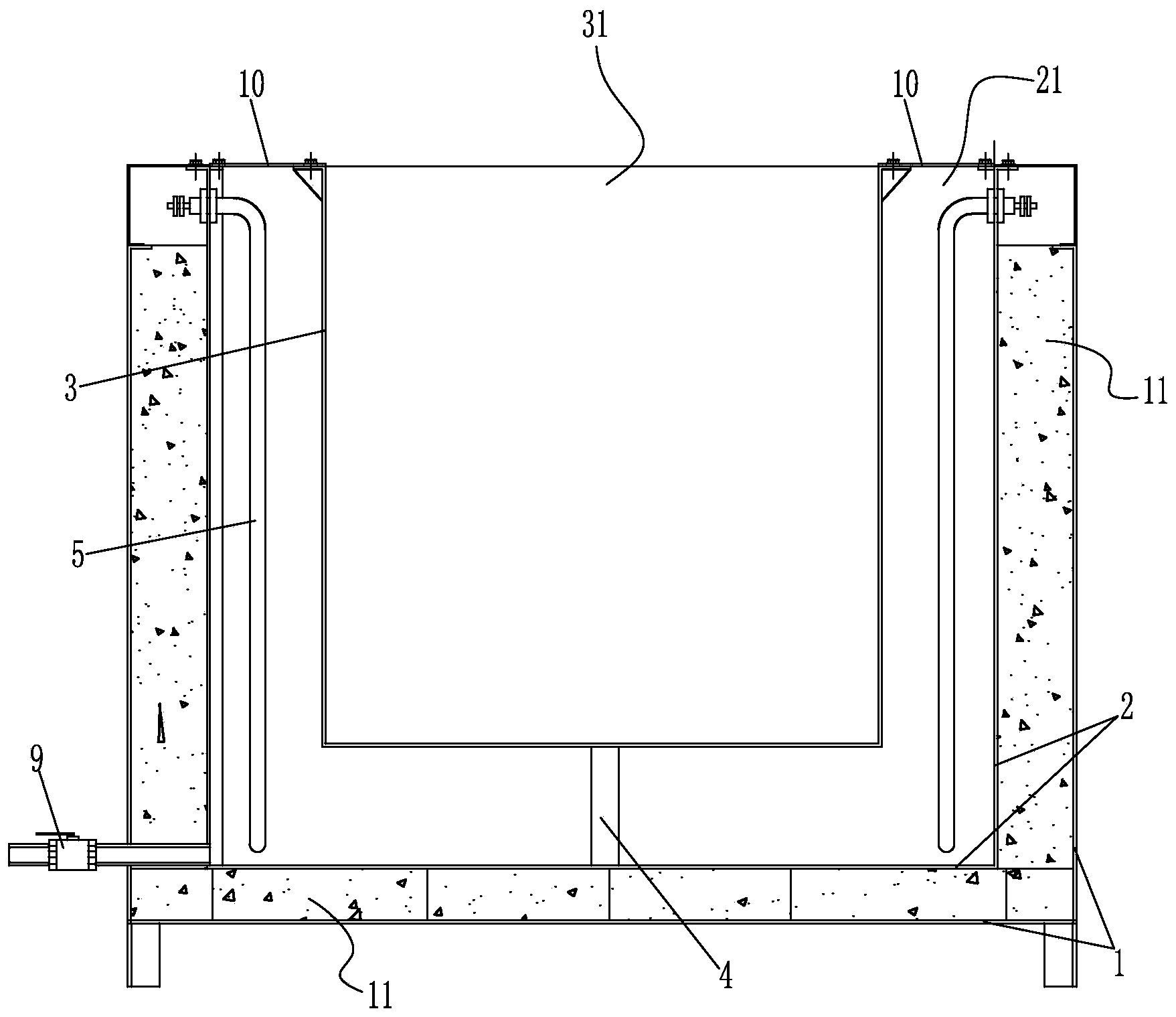

[0011] Such as figure 1 , figure 2 The shown heating oil pool with interlayer includes an outer pool body and an inner pool body 3, the outer pool body includes an outer pool outer wall 1 and an outer pool inner wall 2, and a thermal insulation material 11 is filled between the outer pool outer wall 1 and the outer pool inner wall 2 In the outer pool body, the inner pool body 3 is erected in the air through the bracket 4, and a heat transfer oil cavity 21 for pouring heating oil is formed between the outer pool body and the inner pool body 3, and the heat transfer oil cavity 21 surrounds the surrounding and bottom of the inner pool body 3, and the outer pool body A plurality of heating pipes 5 are installed around the inner wall 2, and the joints of the heating pipes 5 are installed on the upper part of the inner wall 2 of the outer pool. 10. The cover plate 10 is fixedly connected with the outer pool body and the inner pool body 3 to close the heat transfer oil chamber 21. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com