Control system and control method suitable for enabling inclined frame car of inclined ship lift to stably pass through hump

A technology of control system and slanted frame car, which is applied to the machinery, ship lifting device, building and other directions of lifting the ship along the inclined plane. The effect of convenience and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

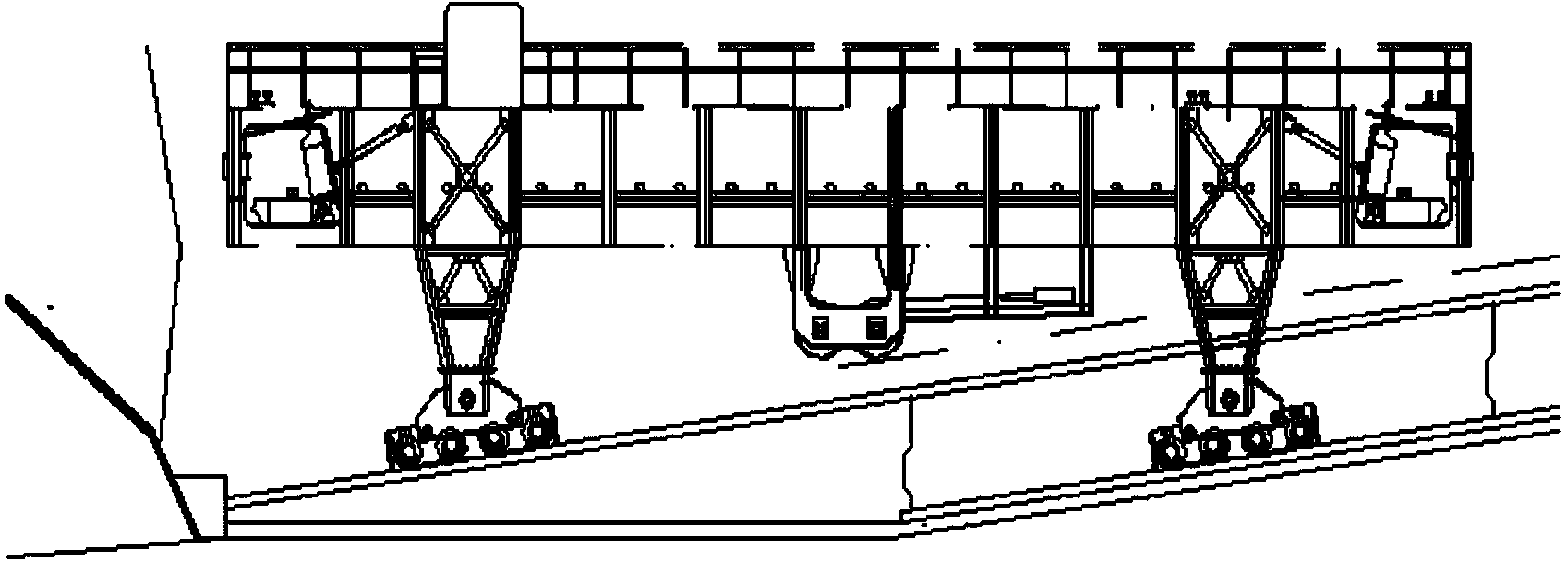

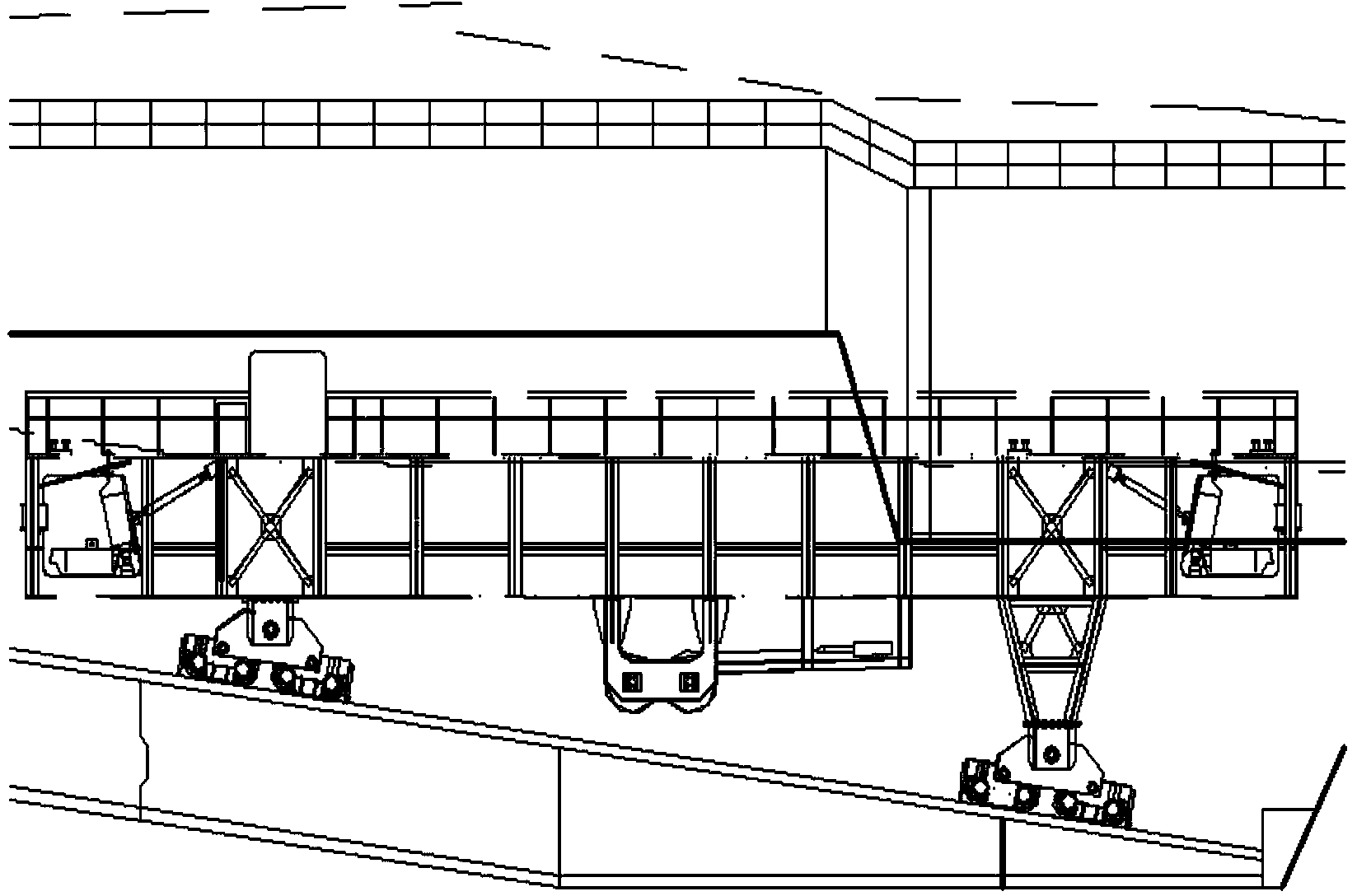

[0025] There are six sets of trolleys under the inclined frame trolley 1, which are supported by four sets of high-leg trolleys when running on the upstream ramp, such as Picture 1-1 As shown, when the downstream ramp is running, it is supported by two sets of high-leg trolleys and two sets of low-leg trolleys among the four sets of high-leg trolleys, such as Figure 1-3 shown.

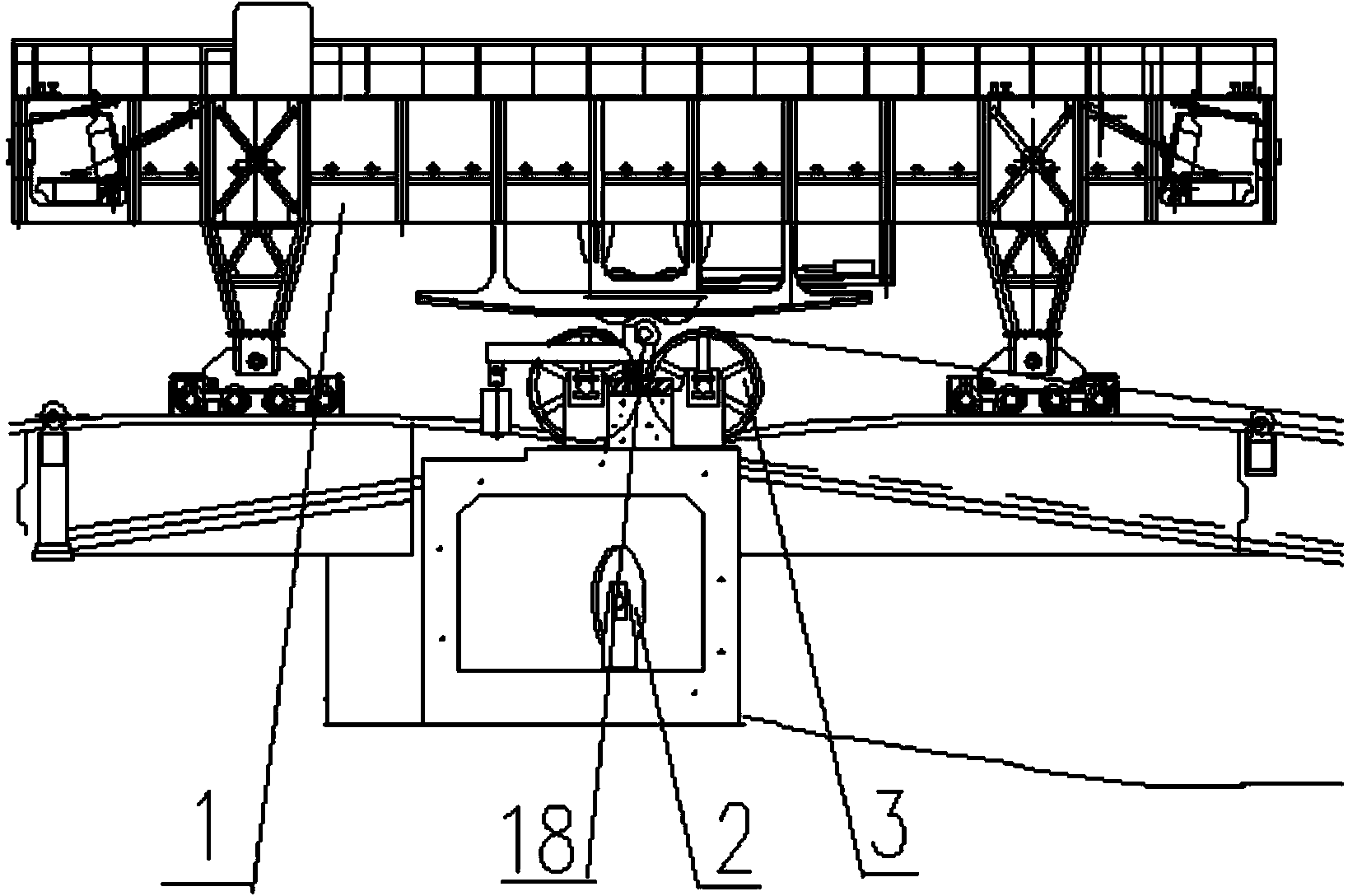

[0026] like Figure 1-2 and figure 2 Shown: the inclined frame car 1 is drawn by four steel wire ropes 12, and a hydraulic equalization oil cylinder is set at the junction of the steel wire ropes 12 and the inclined frame car 1 to balance the tension of each steel wire rope. Wire rope 12 is wound on two reels 9 of hoisting motor 11 after the sky pulley 3 at the top of the hump and the ground pulley 2 at the bottom, and the ropes of the two reels 9 are in opposite directions. Each cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com