Laser beam parallelism adjustment system and laser beam parallelism adjustment method for road surface deflection measurement

A road surface deflection and adjustment system technology, applied in roads, roads, road repairs, etc., can solve problems such as complex operation, high cost, and poor practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

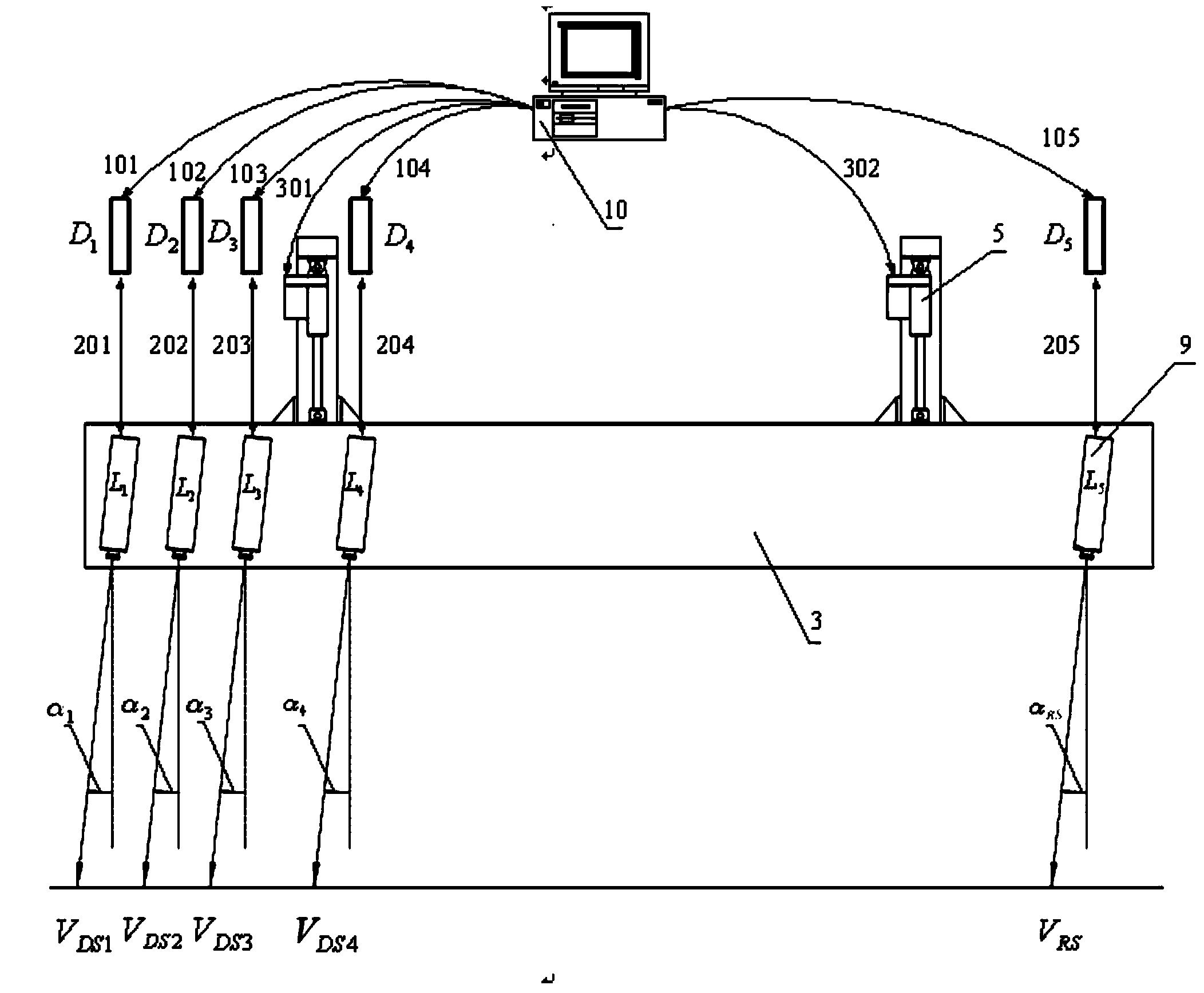

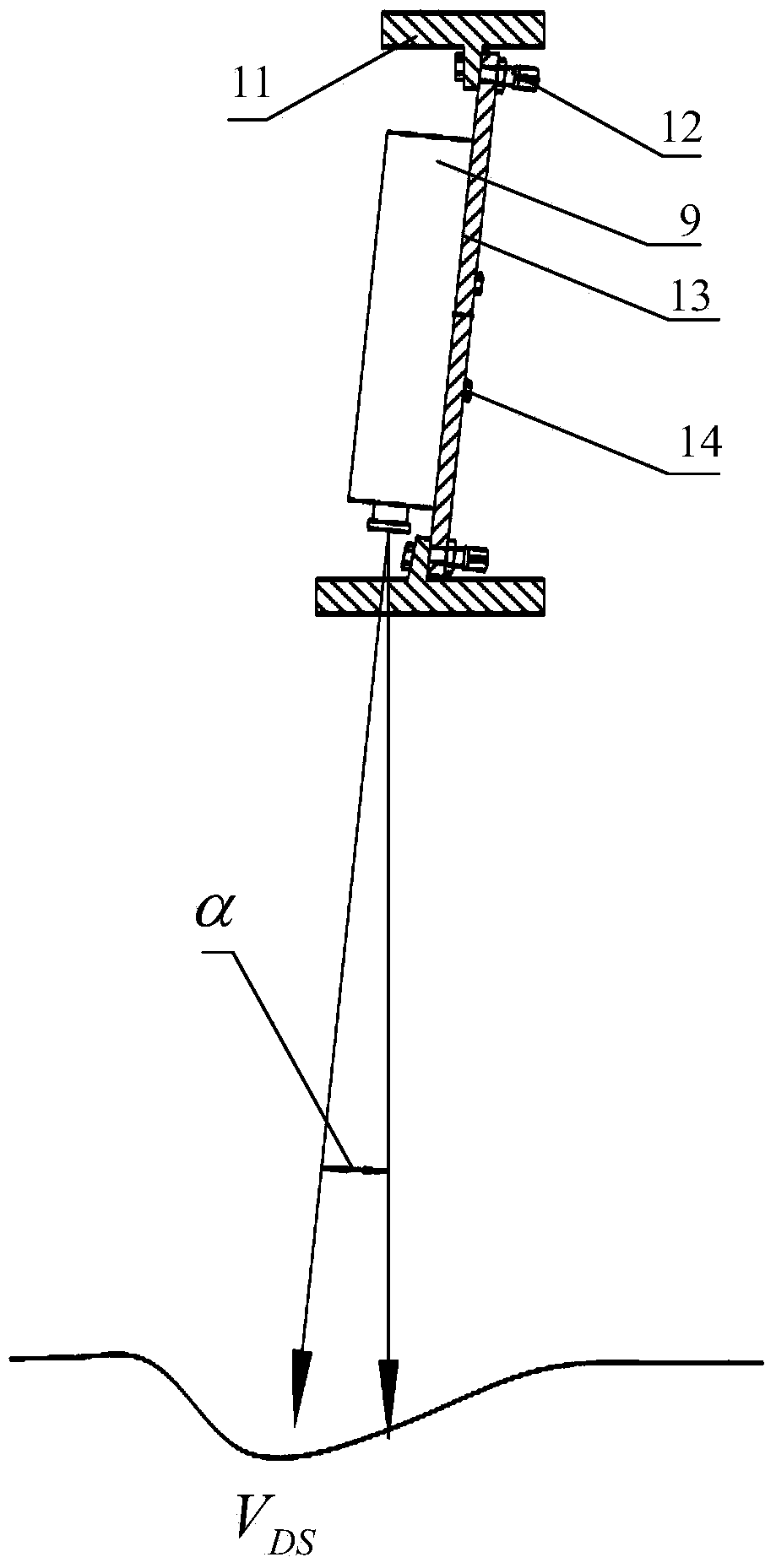

[0046] This scheme mainly uses a set of servo control device to drive the laser test common beam equipped with several laser velocimeters to move vertically. By comparing the vertical movement speed value of the laser test common beam with the speed value of each laser velocimeter, it can be determined Whether the laser beams of each laser velocimeter are parallel. And when the deflection test vehicle is running at normal speed, the actual installation angle value of the reference laser speedometer can be obtained quickly and accurately.

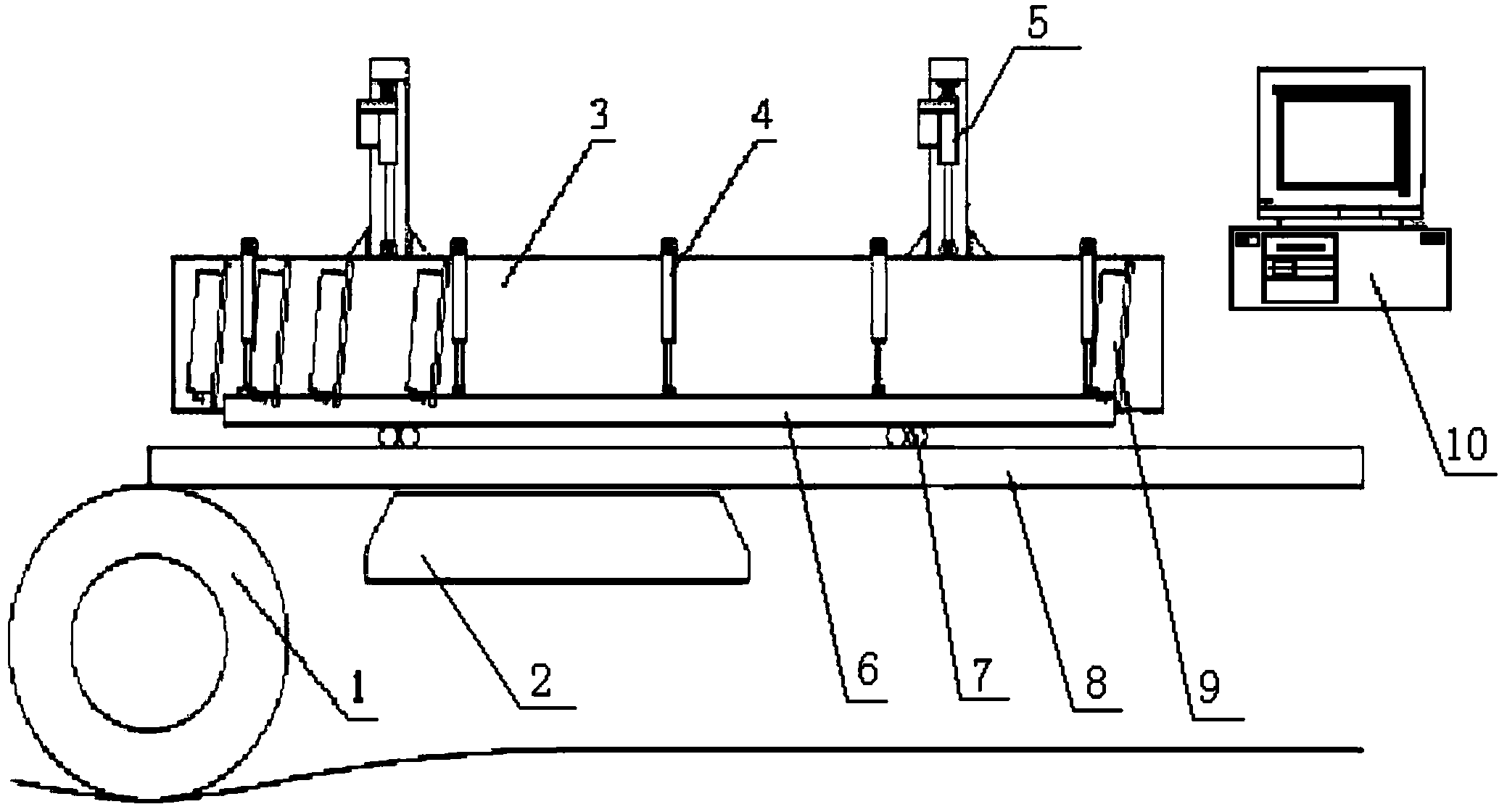

[0047] This system mainly includes laser testing common beam, mobile steel beam frame, guide rail platform, servo control device, signal acquisition system, shock absorption system, load wheel and counterweight, etc. By setting the running speed of the electric p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com