Buncher of drawing frame

The technology of a bundler and a drawing frame is applied in the directions of spinning machines, textiles and papermaking, drafting equipment, etc., and can solve the problems of increased resistance between the bundler and the fiber, re-flowering of the bundler, and easy to bring in the sliver, etc. Achieves improved yarn defect levels, reduced resistance, reduced pattern build-up and re-patterning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

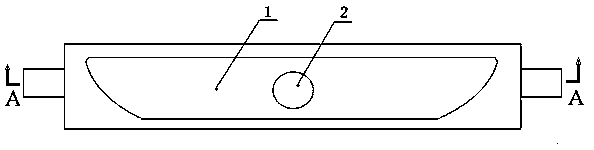

[0016] Figure 3 is a schematic front view of the structure of the present invention.

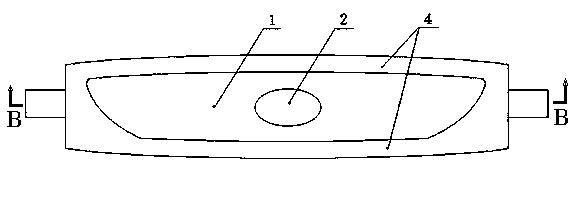

[0017] Figure 4 is a schematic top view of the structure of the present invention.

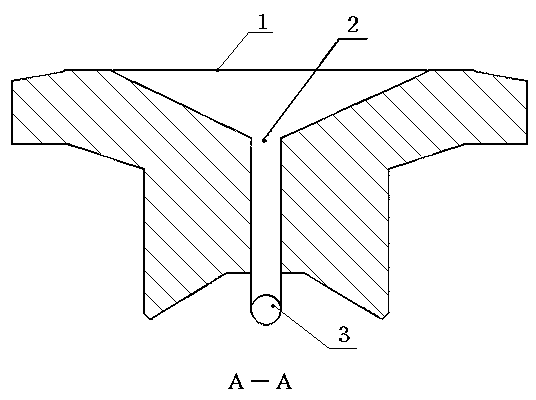

[0018] The present invention includes a cluster body, and the cluster body is provided with a cluster inlet 1, a cluster outlet 2 and a cluster gathering port 3.

[0019] The inner diameter of the inlet 1 of the cluster is 25mm at the narrow part and 28mm at the wide part.

[0020] The outlet 2 of the cluster is elliptical, and its inner diameter is 15mm-13mm.

[0021] The three openings of the bundler are arc-shaped, with an inner diameter of 15mm-20mm. The arc shape increases the angle, so that the cotton web is more relaxed than before when the bundler is gathered, and the resistance of the bundler to the cotton mesh is greatly reduced. Small, the fiber can pass through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com