Coix seed wine and making method thereof

A production method and technology of coix seed wine, which is applied in the field of coix seed wine and its production, can solve the problems of heavy nutritional loss, easy spicy taste, and topping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

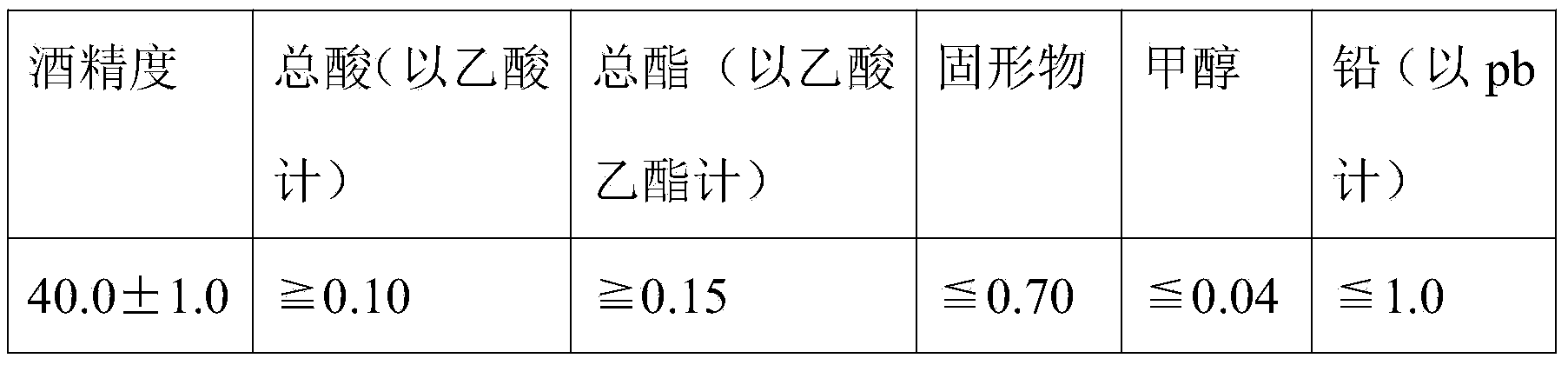

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

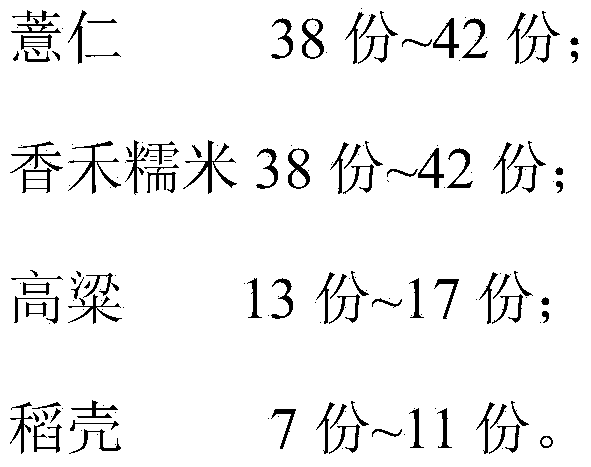

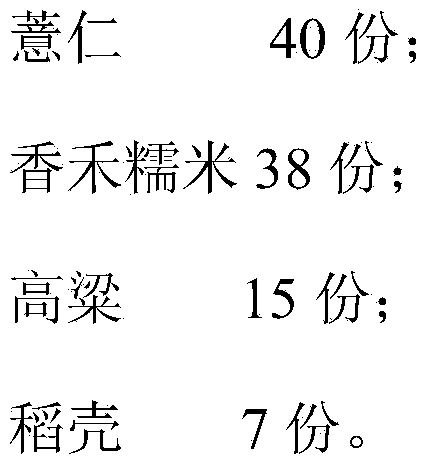

[0039] Raw material proportioning by weight:

[0040] 40 parts of barley; 38 parts of Xianghe glutinous rice; 15 parts of sorghum; 7 parts of rice husk.

[0041] Production Method:

[0042] (1) Mixing, stirring and soaking of raw materials, and draining:

[0043]Take barley, fragrant grass glutinous rice, sorghum, and rice husk in proportion by weight, mix them well, soak them in warm water at 40°C for 120 minutes, then remove them and filter them dry for 60 minutes;

[0044] (2) After steaming, take it out and let it dry:

[0045] Steam the dried raw material mixture in step (1) at 150°C for 60 minutes, then take it out and let it dry for 180 minutes;

[0046] (3) Add shochu koji and stir evenly, saccharify and ferment:

[0047] Add Xiaoxian brand shochu koji, which accounts for 0.5% of the mass of the air-drying material, to the air-drying material obtained in step (2), stir evenly, and send it to the saccharification tank for accumulation and saccharification. After the...

Embodiment 2

[0053] Raw material proportioning by weight:

[0054] 38 parts of barley; 42 parts of Xianghe glutinous rice; 16 parts of sorghum; 8 parts of rice husk.

[0055] Production Method:

[0056] (1) Mixing, stirring and soaking of raw materials, and draining:

[0057] Take barley, fragrant grain glutinous rice, sorghum, and rice husk in proportion by weight, mix them well, soak them in warm water at 39°C for 115 minutes, then take them out and filter them dry for 50 minutes;

[0058] (2) After steaming, take it out and let it dry:

[0059] Steam the dried raw material mixture in step (1) at 1445°C for 55 minutes, then take it out and let it dry for 175 minutes;

[0060] (3) Add shochu koji and stir evenly, saccharify and ferment:

[0061] Add shochu koji, which accounts for 0.4% of the mass of the air-drying material, to the air-drying material obtained in step (2), stir evenly, and send it to the saccharification tank for accumulation and saccharification. After the saccharifi...

Embodiment 3

[0067] Raw material proportioning by weight:

[0068] 39 parts of Job's tears; 41 parts of Xianghe glutinous rice; 17 parts of sorghum; 9 parts of rice husk.

[0069] Production Method:

[0070] (1) Mixing, stirring and soaking of raw materials, and draining:

[0071] Take barley, fragrant grass glutinous rice, sorghum, and rice husk in proportion by weight, mix them well, soak them in warm water at 38°C for 110 minutes, then take them out and filter them dry for 55 minutes;

[0072] (2) After steaming, take it out and let it dry:

[0073] Steam the dried raw material mixture in step (1) at 155°C for 65 minutes, then take it out and let it dry for 185 minutes;

[0074] (3) Add shochu koji and stir evenly, saccharify and ferment:

[0075] Add Xiaoxian brand shochu koji, which accounts for 0.6% of the mass of the air-drying material, to the air-drying material obtained in step (2), stir evenly, and then send it to the saccharification tank for accumulation and saccharificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com