Wax-based binder for compacting process in powder metallurgy as well as preparation method and application thereof

A technology of powder metallurgy and binder, applied in the field of binder for powder molding or injection molding, to achieve high solvent degreasing rate, increase degreasing rate, increase solvent degreasing rate and degreasing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The binder formula is: calculated by mass percentage, 77% paraffin, 5% liquid paraffin, 3% naphthalene, 4% polyethylene vinyl acetate, 5% polypropylene, and 6% stearic acid.

[0040] Preparation method: first heat the kneader, add solid paraffin when the temperature rises to about 100°C, add polyethylene vinyl acetate and polypropylene after the solid paraffin melts, and then continue to heat up to about 165°C, through the continuous stirring of the kneader blades Mix to make polyethylene vinyl acetate and polypropylene melt; then adjust the temperature of the kneader to about 140°C, knead for 20-30 minutes to make it evenly mixed, and finally adjust the temperature of the kneader to about 110°C again, and add all the naphthalene and liquid For paraffin wax, it can be stirred and kneaded by the kneader for 10-15 minutes.

Embodiment 2

[0042] The binder formula is: calculated by mass percentage, 63wt% paraffin, 7wt% liquid paraffin, 8% naphthalene, 3.5wt% polyethylene vinyl acetate, 3.5% polypropylene, 10wt% low-density polyethylene, 5wt% hard Fatty acid. The preparation method is the same as in Example 1.

Embodiment 3

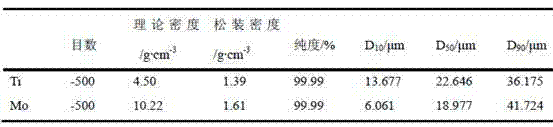

[0045] Example 3 Titanium hydride powder injection molding

[0046] Raw material titanium hydride powder characteristics: D50=10.13μm, bulk density 1.86 g / cm 3 , tap density 2.37g / cm 3 , purity>99.1%.

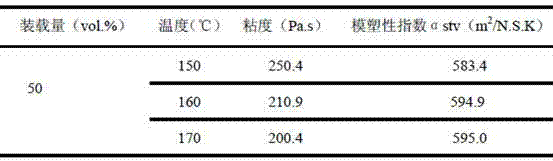

[0047] When using a conventional paraffin-based binder (mass percentage composition: 73% paraffin, 21% high-density polyethylene, 6% stearic acid, comparative example 1) as a binder, the loading of titanium hydride powder is 57vol .%.

[0048] When using binding agent of the present invention (77% paraffin, 5% liquid paraffin, 3% naphthalene, 4% polyethylene vinyl acetate, 5% polypropylene, 6% stearic acid, embodiment 1) as binding agent, The loading of titanium hydride powder reaches 70vol.%. The test results during the solvent degreasing process show that, compared with conventional paraffin-based binders, the degreasing rate of the binder is increased by 20% to 30% under the same process conditions.

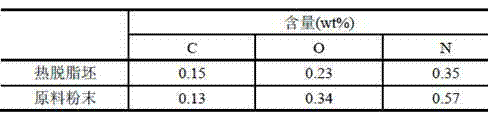

[0049] When using the binder of the present invention, the impurity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com