A kind of preparation method of diesterification composite starch

A compound type, double-esterification technology, applied in the field of starch processing, can solve the problems of low degree of long-chain esterification reaction, difficulty in meeting environmental protection emulsification performance, low starch utilization rate, etc., achieve good application effect, improve chemical reaction, The effect of lowering the gelatinization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

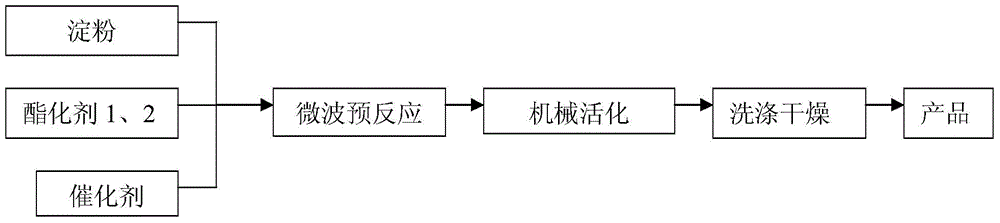

Method used

Image

Examples

Embodiment 1

[0023] The short-chain acid (anhydride) esterification agent 1 used in this example is a composition composed of acetic acid and succinic anhydride in a weight ratio of 3:1; the long-chain acid (anhydride) esterification agent 2 is octenyl succinic anhydride ; Catalyst is K 2 CO 3 and Na 2 CO 3 According to the weight ratio of 0.2g:0.3g mixed composition.

[0024]According to the ratio of starch: short-chain acid (anhydride) esterification agent 1: long-chain acid (anhydride) esterification agent 2: catalyst=100g: 4g: 3g: 0.5g, the reaction material is weighed, after the reaction material is mixed evenly, add to In microwave equipment, microwave treatment for 10 minutes under the condition of 750W. Step 2) mechanical activation: put the reaction material after microwave treatment into a ball mill, and add a short-chain acid (anhydride) esterification agent 1 equivalent to 2.5% of the weight of the reaction material to control the reaction material and ball (pile volume) R...

Embodiment 2

[0027] The short-chain acid (anhydride) esterification agent 1 used in this example is acetic anhydride; the long-chain acid (anhydride) esterification agent 2 is lauric acid, palmitic acid, stearic acid according to the weight ratio 1g: 1g: 2g mixed The composition; the catalyst is NaOH.

[0028] According to the ratio of starch: short-chain acid (anhydride) esterification agent 1: long-chain acid (anhydride) esterification agent 2: catalyst=100g: 1g: 4g: 0.7g, the reaction material is weighed, after the reaction material is mixed evenly, add to In microwave equipment, microwave treatment under the condition of 500W for 8min. Step 2) mechanical activation: put the reaction material after microwave treatment into a ball mill, and add a short-chain acid (anhydride) esterification agent 1 equivalent to 4% of the weight of the reaction material to control the reaction material and ball (pile volume) Ratio = 100g: 200ml, stirring at a low speed at 40°C for 70 minutes for esterifi...

Embodiment 3

[0031] The short-chain acid (anhydride) esterifying agent 1 used in the present embodiment is the composition that adipic acid and succinic acid mix according to weight ratio 1g:2g; The long-chain acid (anhydride) esterifying agent 2 is stearic acid ; Catalyst is H 2 SO 4 (50% aqueous sulfuric acid).

[0032] According to the ratio of starch: short-chain acid (anhydride) esterification agent 1: long-chain acid (anhydride) esterification agent 2: catalyst=100g: 3g: 3.5g: 0.1g, the reaction material is weighed, after the reaction material is mixed uniformly, add In the microwave equipment, microwave treatment under the condition of 650W for 2min. Step 2) Mechanical activation: put the microwave-treated reaction material into a ball mill, and add short-chain acid (anhydride) esterification agent 1 equivalent to 1.5% by weight of the reaction material: long-chain acid (anhydride) esterification agent 2 : Catalyst=3g: 3.5g: 0.1g ratio mixed composition, control the ratio of reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap