Method for jointly producing glycol ether and ethylene glycol diethyl ether by adopting ethylene glycol as raw material

A technology of ethylene glycol diethyl ether and ethylene glycol ethyl ether, which is used in ether preparation, dehydration of hydroxyl-containing compounds to prepare ether, organic chemistry, etc., can solve problems such as transportation difficulties and production site restrictions, and achieve high activity and good stability , high conversion rate and selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

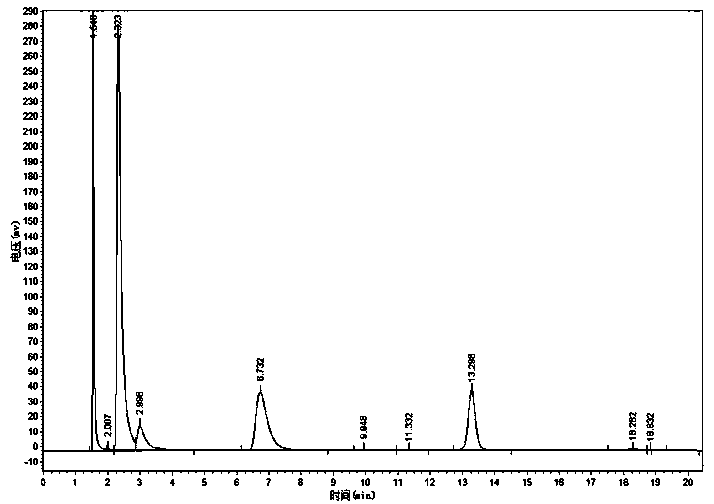

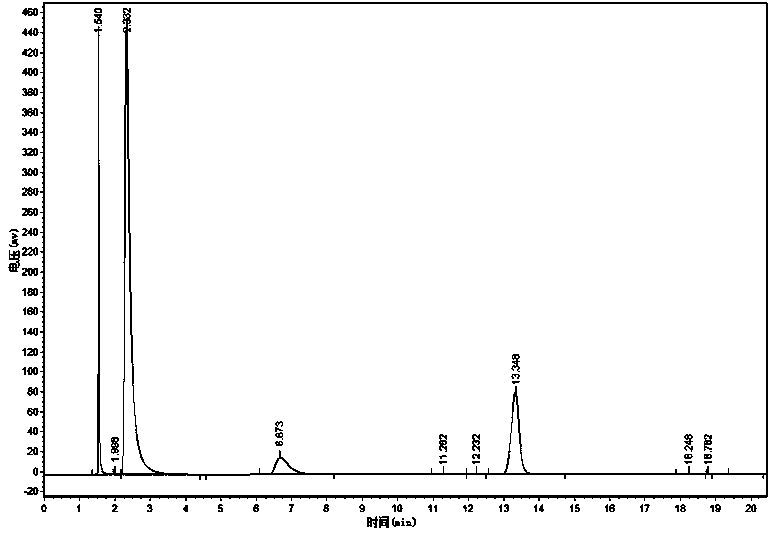

Image

Examples

Embodiment 1

[0060] 1 part of SiO 2 / Al 2 o 3 (mass ratio 80:1), add 0.1-10.0mol / L H + ,Al 3+ and SO 4 2- , Cl - In the modified agent solution composed, it was impregnated in excess for 10 hours, dried at 120°C for 2 hours, and calcined in vacuum at 700°C for 6 hours to obtain powdery catalyst A.

Embodiment 2

[0062] Add 20ml and 4ml of tetrabutyl titanate into 50ml of absolute ethanol, stir for 30 minutes to obtain a mixture, add 1ml of nitric acid and 20ml of absolute ethanol mixture into a, stir for 1 hour, age at 70°C for 3 hours, 120°C After the drying is complete, the solid is obtained, and after being ground into a powder, it is placed in 0.1-10.0mol / L H + ,Al 3+ and SO 4 2- , Cl - After immersing in the modified agent of the composition for 24 hours, drying at 120°C for 6 hours, and calcining in a carbon dioxide atmosphere at 500°C for 4 hours, the powder catalyst B was obtained.

Embodiment 3

[0064] 10 g SiO 2 / Al 2 o 3 (Mass ratio is 25:1) Add 20ml of 0.5-2.0mol / L H + ,Al 3+ and SO 4 2- , NO 3 - Immerse in the modifier solution formed for 12 hours, filter under reduced pressure, dry the filter cake at 120°C, and bake the solid at 800°C for 10 hours in an air atmosphere, then naturally cool to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com