Method for increasing the silicon-aluminum ratio of y-type molecular sieve framework

A technology of molecular sieve and silicon-aluminum ratio, which is applied in the field of preparation and improvement of Y-type molecules, can solve problems such as incomplete structure, weak acid resistance, and increased energy consumption, and achieve the effects of no toxic side effects, low price, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

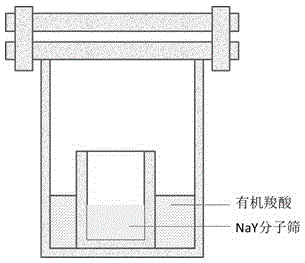

[0033] Put 5.0g NaY molecular sieve in a 25ml beaker, 5.0g formic acid in a 100ml autoclave lining, and place a small beaker in the autoclave lining to avoid contact between the molecular sieve and the organic carboxylic acid. After sealing, heat treatment at 150°C for 12 hours. The steam-treated Y-type molecular sieve was taken out and dried at 80°C. The resulting dried solid sample was designated S-1.

Embodiment 2

[0035] Put 5.0g HY molecular sieve in a 25ml beaker, 5.0g formic acid in a 100ml autoclave lining, and place a small beaker in the autoclave lining to avoid contact between the molecular sieve and the organic carboxylic acid. After sealing, heat treatment at 150°C for 12 hours. The steam-treated Y-type molecular sieve was taken out and dried at 80°C. The resulting dried solid sample was designated S-2.

Embodiment 3

[0037] Put 5.0g HY molecular sieve in a 25ml beaker, 5.0g acetic acid in a 100ml autoclave lining, and place a small beaker in the autoclave lining to avoid contact between the molecular sieve and the organic carboxylic acid. After sealing, heat treatment at 150°C for 12 hours. The steam-treated Y-type molecular sieve was taken out and dried at 80°C. The resulting dried solid sample was designated S-3.

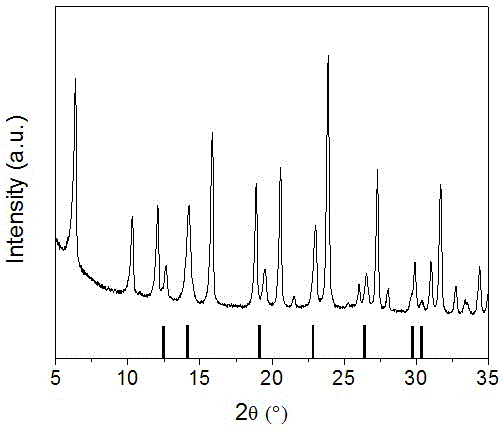

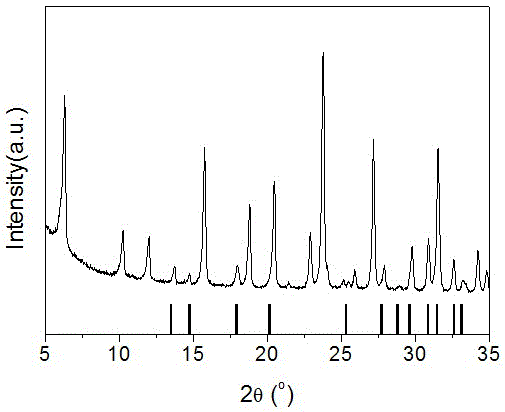

[0038] From the above results, it can be seen that it is feasible to dealuminate Y-type molecular sieves with organic carboxylic acids, but in conventional methods, the crystallinity of Y-type molecular sieves will be damaged to a greater extent when the framework is dealuminated. Scales 1, 3 are shown. Due to the strong acidity of formic acid in the solution, the framework of the molecular sieve is severely damaged during dealumination; lactic acid is a hydroxycarboxylic acid, which has a certain coordination effect on the aluminum in the framework of the molecular sieve, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com