Preparation method of cassava-starch-based grading-pore carbon microsphere material

A technology of cassava starch and hierarchical pore carbon, which is applied in the direction of carbon preparation/purification to achieve the effect of low price and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

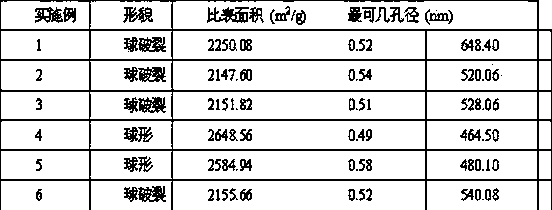

Examples

Embodiment 1

[0025] Enzymatic hydrolysis of tapioca starch to prepare porous starch: Weigh 30 grams of tapioca starch, add it to a sandwich bottle filled with 45 ml of buffer solution (HAc-NaAc) with a pH of 4.7, preheat it in a water bath at 42 degrees for 10 minutes, and then Add 0.60 g of glucose and 0.15 g of amylase into the system, keep stirring in a 42-degree water bath for 24 hours for enzymolysis reaction, wash with deionized water to neutral after reaction, and freeze-dry to obtain porous starch.

[0026] Then the porous tapioca starch is pretreated: take 25 grams of porous starch and put it into a 180 degree oven for pretreatment for 4 hours.

[0027] Then the porous tapioca starch after pretreatment is put into tube furnace, under nitrogen atmosphere, gas flow rate is 30 milliliters / minute, rises to 500 degrees from room temperature by 2 degrees / minute heating rate and is incubated 1 hour;

[0028] Mechanically mix the carbonized porous tapioca starch with potassium hydroxid...

Embodiment 2

[0032] According to the enzymatic hydrolysis method described in Example 1, porous starch was obtained as a raw material for pretreatment: 25 grams of porous starch was weighed, and pretreated in an oven at 200 degrees for 4 hours.

[0033] Put the pretreated porous tapioca starch into a tube furnace, under a nitrogen atmosphere, the gas flow rate is 70 ml / min, and the temperature rises from room temperature to 600 degrees at a rate of 2 degrees per minute and is kept for 1 hour.

[0034] Mechanically mix the carbonized porous tapioca starch with potassium hydroxide, wherein the carbon-to-alkaline ratio (mass ratio) is 1:8, put it into a tube furnace, and in a nitrogen atmosphere, the gas flow rate is 100 ml / min, press 5 Degrees per minute The heating rate is raised from room temperature to 950 degrees and kept for 3 hours. After the product is cooled, it is washed with dilute hydrochloric acid, then washed with distilled water until the pH value of the washing solution is 6, a...

Embodiment 3

[0036] According to the enzymatic hydrolysis method described in Example 1, porous starch was obtained as a raw material for pretreatment: 25 grams of porous starch was weighed, and pretreated in an oven at 200 degrees for 16 hours.

[0037] Put the pretreated porous tapioca starch into a tube furnace, under a nitrogen atmosphere, the gas flow rate is 30 ml / min, and the temperature rise rate is 1 degree / min from room temperature to 700 degrees and kept for 1 hour.

[0038] Mechanically mix the carbonized porous tapioca starch with potassium hydroxide, wherein the carbon-to-alkaline ratio (mass ratio) is 1:5, put it into a tube furnace, and in a nitrogen atmosphere, the gas flow rate is 100 ml / min, press 4 Degrees per minute The heating rate is raised from room temperature to 950 degrees and kept for 3 hours. After the product is cooled, it is washed with dilute hydrochloric acid, then washed with distilled water until the pH value of the washing solution is 7, and then dried at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com