Liquid pouring opening leakage-proof matching highlight bottle

A leak-proof and liquid-pouring technology, which is applied to bottles, bottle/can parts, containers, etc., can solve the problems of high production cost, complex structure, liquid leakage, etc. bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

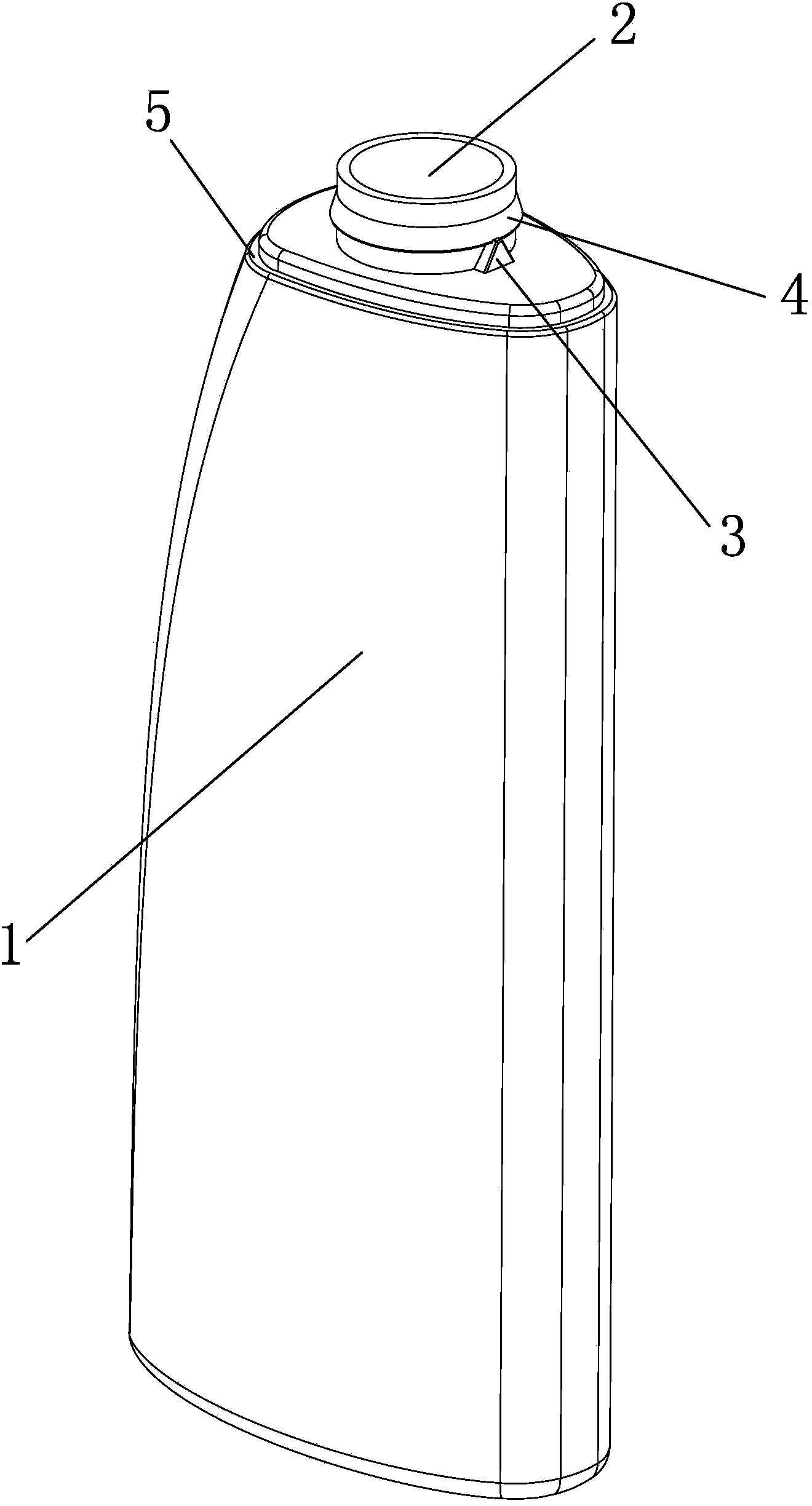

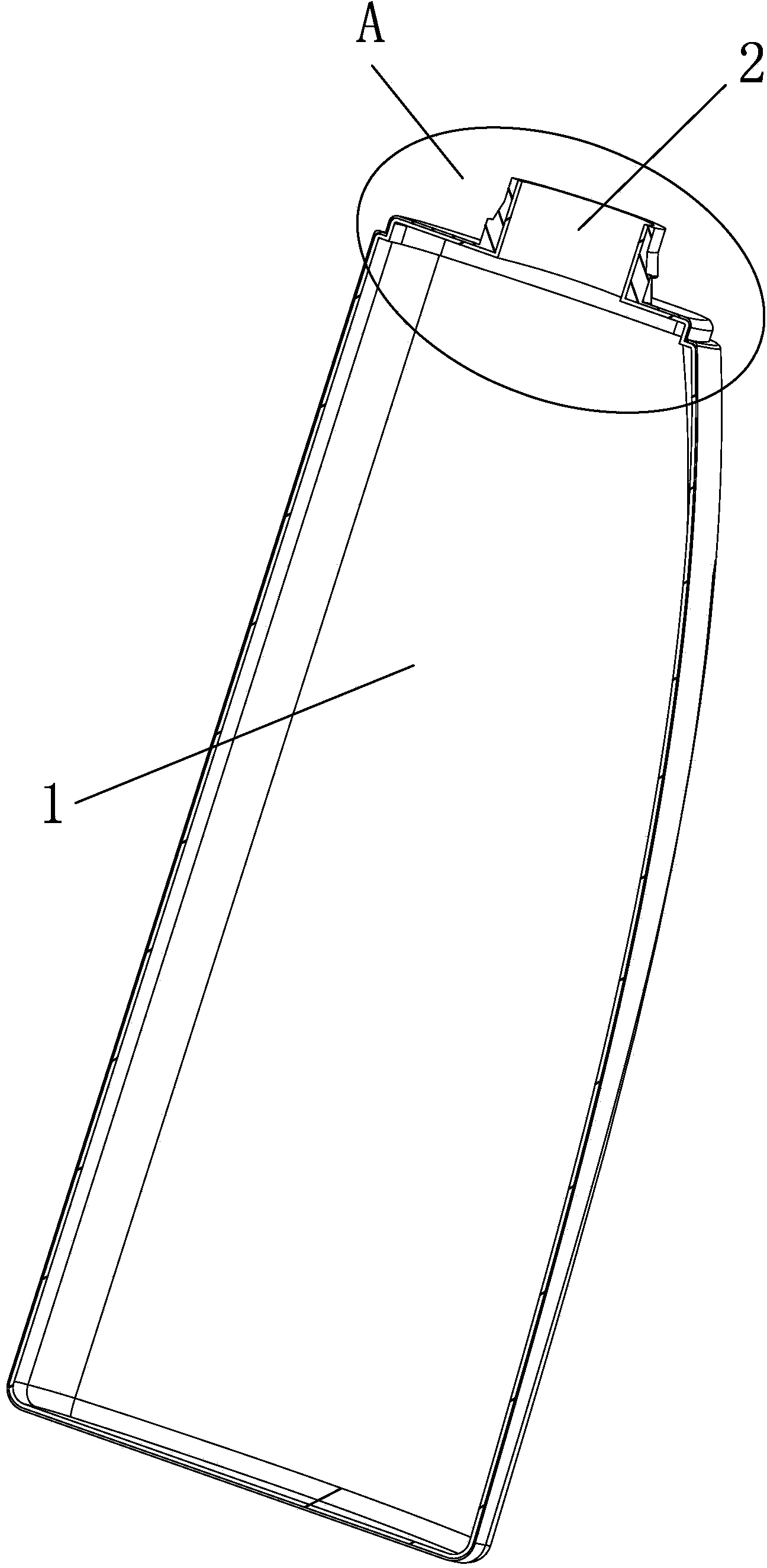

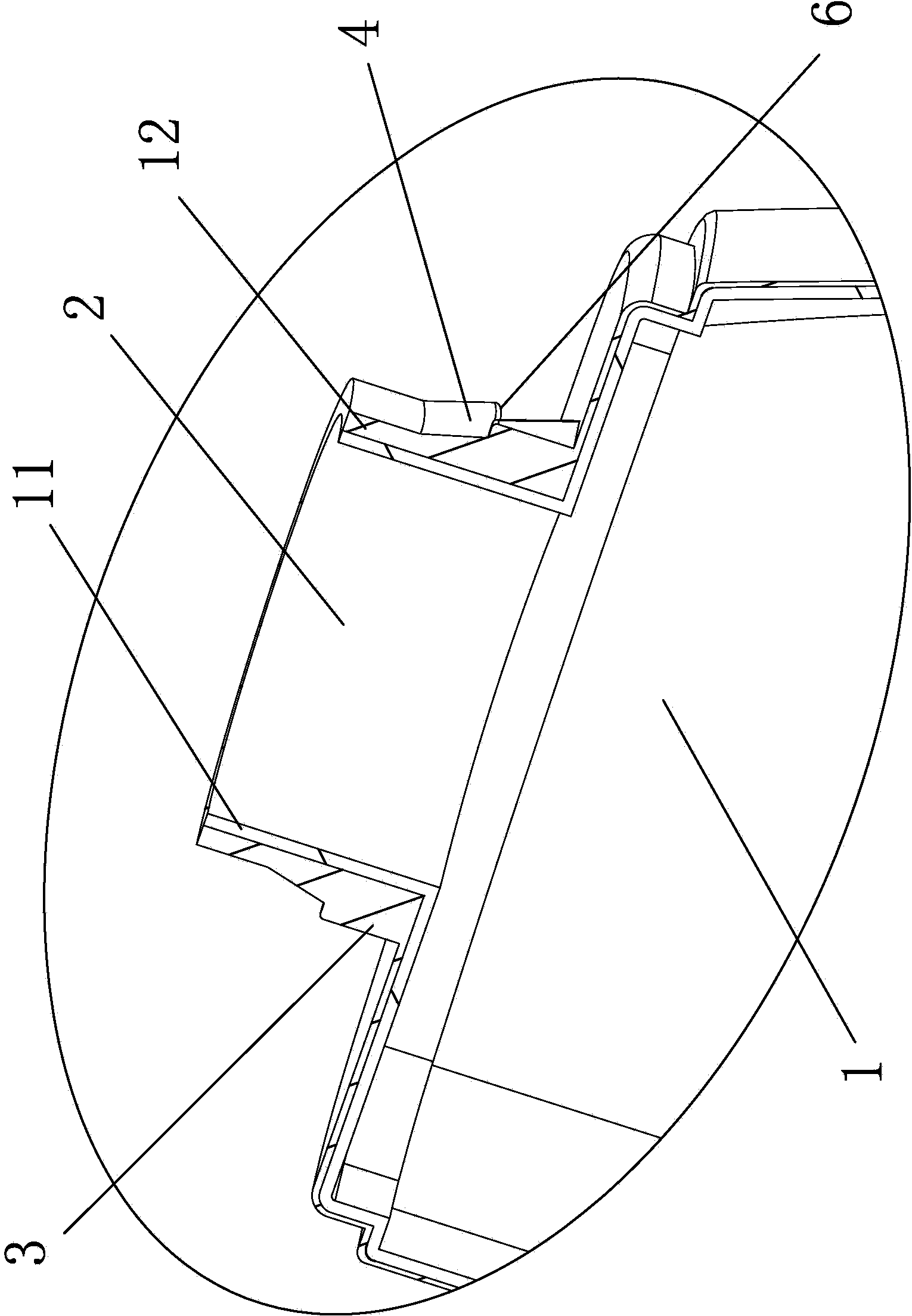

[0016] Such as Figures 1 to 3 A leak-proof matching high-gloss bottle with a liquid pouring port as shown includes a bottle body 1. The bottle body 1 includes a PE inner layer 11, and a PP outer layer 12 is arranged outside the PE inner layer 11. The upper end surface of the bottle body 1 is provided with a bottleneck 2 communicating with the inner cavity of the bottle body 1, and a limiting protrusion 3 is arranged on the outer wall of the bottleneck 2, and the bottleneck 2 above the limiting protrusion 3 The outer wall is provided with a connecting ring 4 for connecting with the bottle cap. The product structure of the invention is simple, and the high-gloss effect is realized by co-extruding two layers of materials, that is, the inner layer adopts PE material + color masterbatch, and the outer layer adopts PP material, which effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com