Alternately compressing lamination station device

A lamination table and lamination technology, applied in the field of battery cell manufacturing and battery manufacturing equipment, can solve problems such as affecting the quality and accuracy of laminations, affecting lamination speed, poor adaptability, etc., to improve efficiency and save time. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

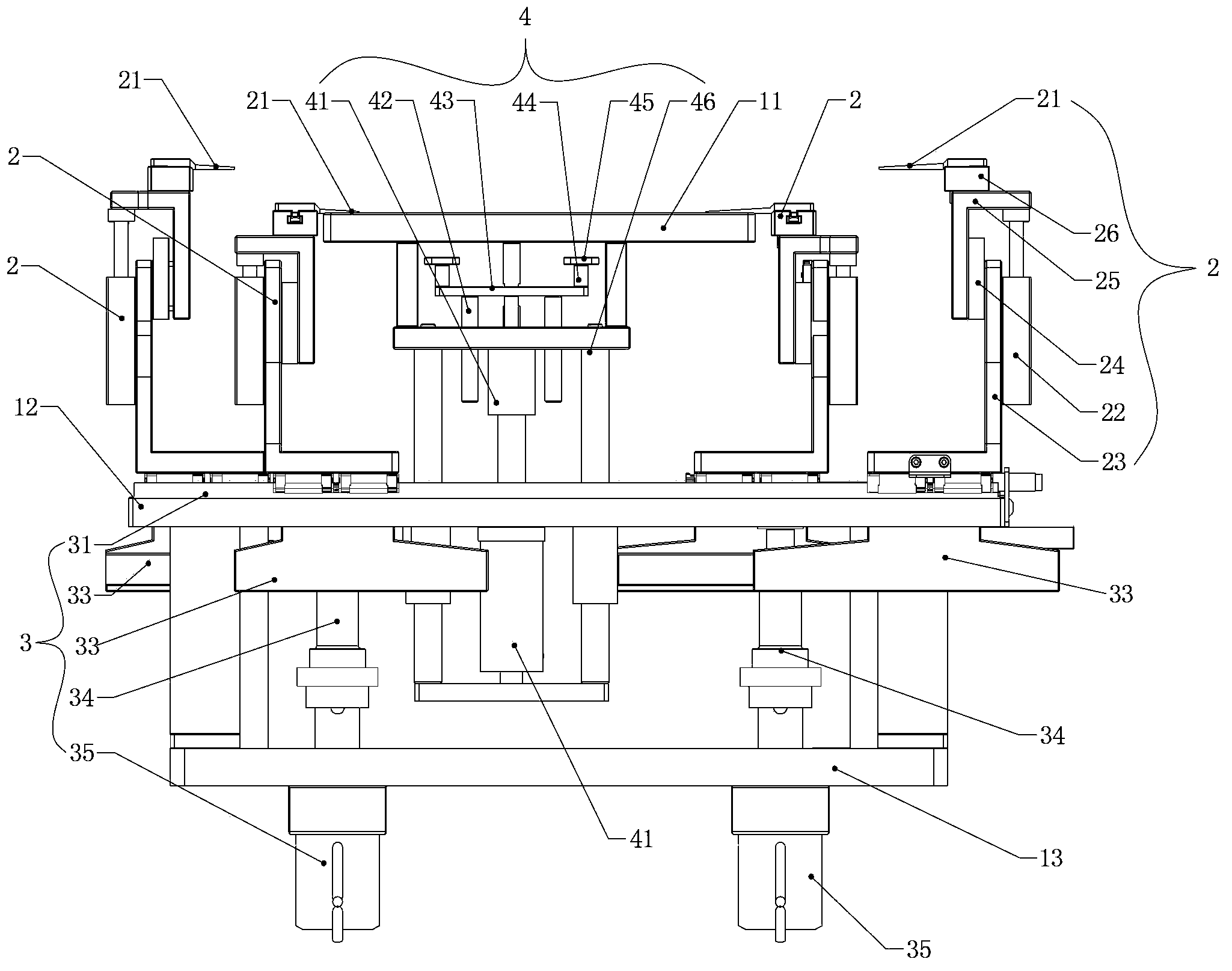

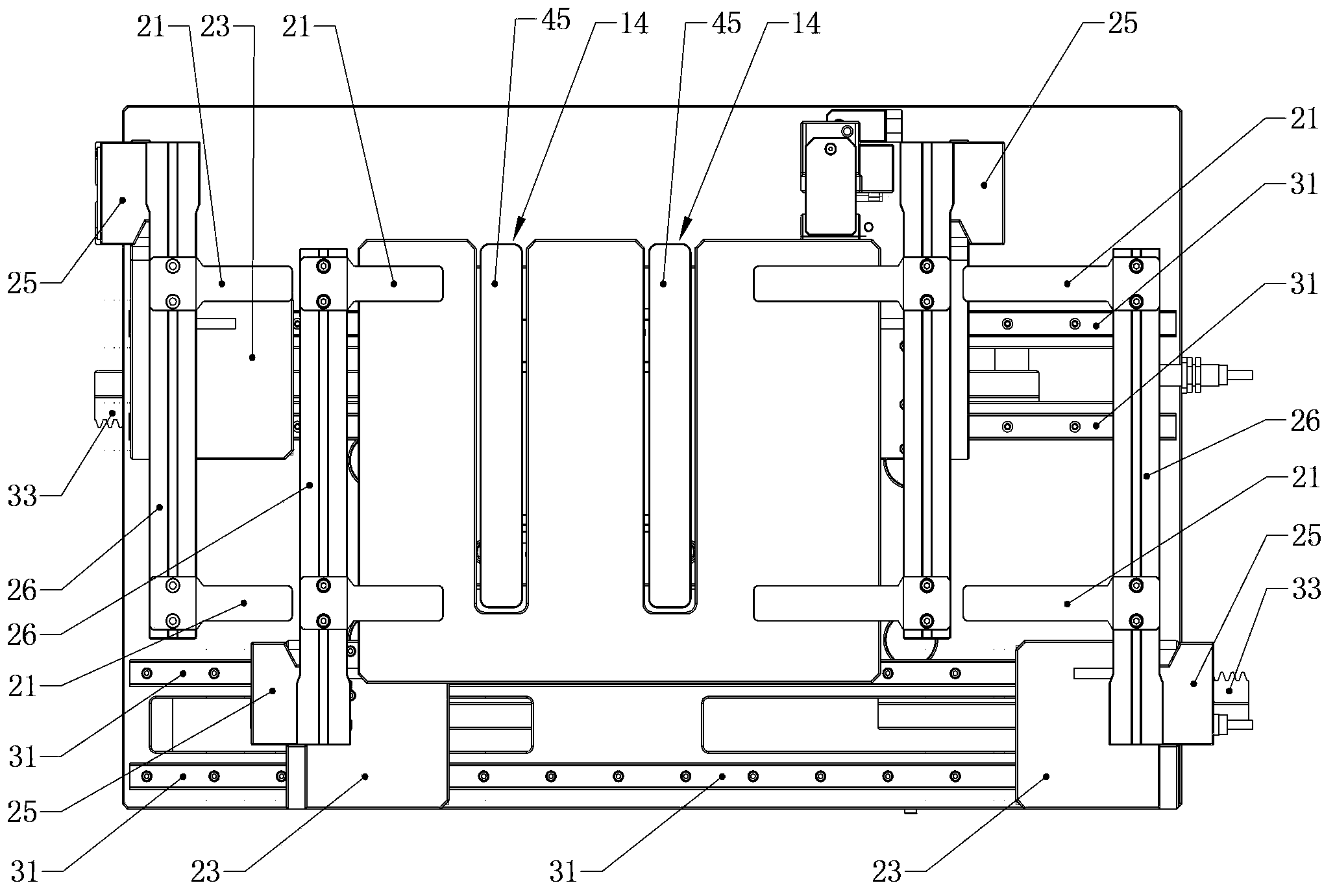

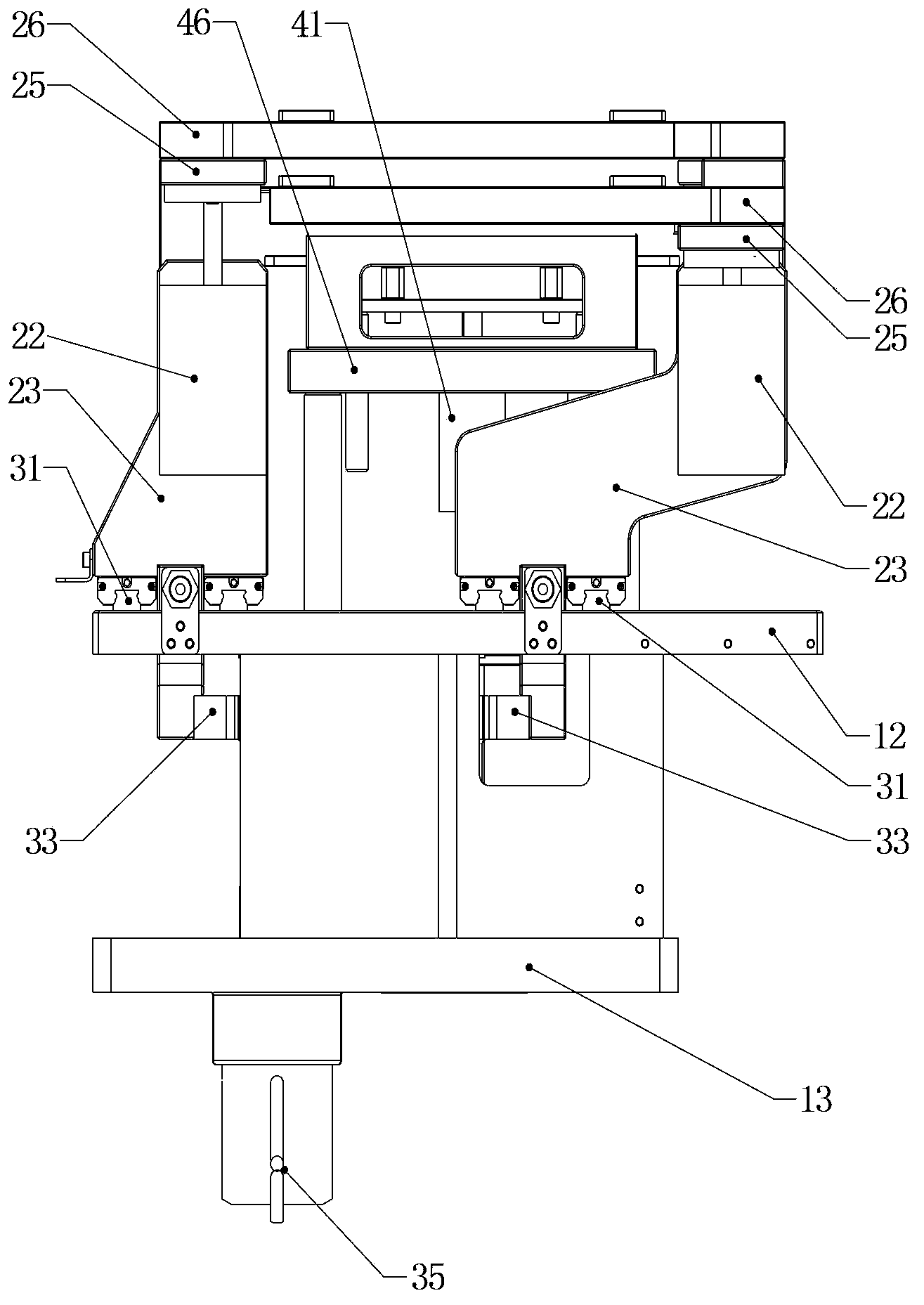

[0026] figure 1 It is the front view of the embodiment of the alternately compacted lamination table device of the present invention, figure 2 is a top view of the structure of this embodiment, image 3 is the left side view of this embodiment.

[0027] The lamination table 1 of the alternate pressing lamination table device embodiment of the present invention has two groups of pressing claw mechanisms 2 that alternately act on the lamination table panel 11 at its two ends. The two sets of moving mechanisms 3 below the lamination table panel 11 respectively drive the two sets of claw mechanism 2 at one end of the lamination table 1 to approach or move away from the lamination table 1 alternately. A replacement mechanism 4 for filling the jaw position groove 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com