Multistage sampling and system analyzing method for analyzing nonmetallic inclusions in steels

A non-metallic inclusions, system analysis technology, applied in the field of multi-stage sampling and system analysis method for analyzing non-metallic inclusions in steel, can solve the problem of affecting steel properties, reducing steel mechanical properties and corrosion fatigue limit, reducing steel strength, etc. problems, to achieve the effects of improving production efficiency, improving the development of new steel types, and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

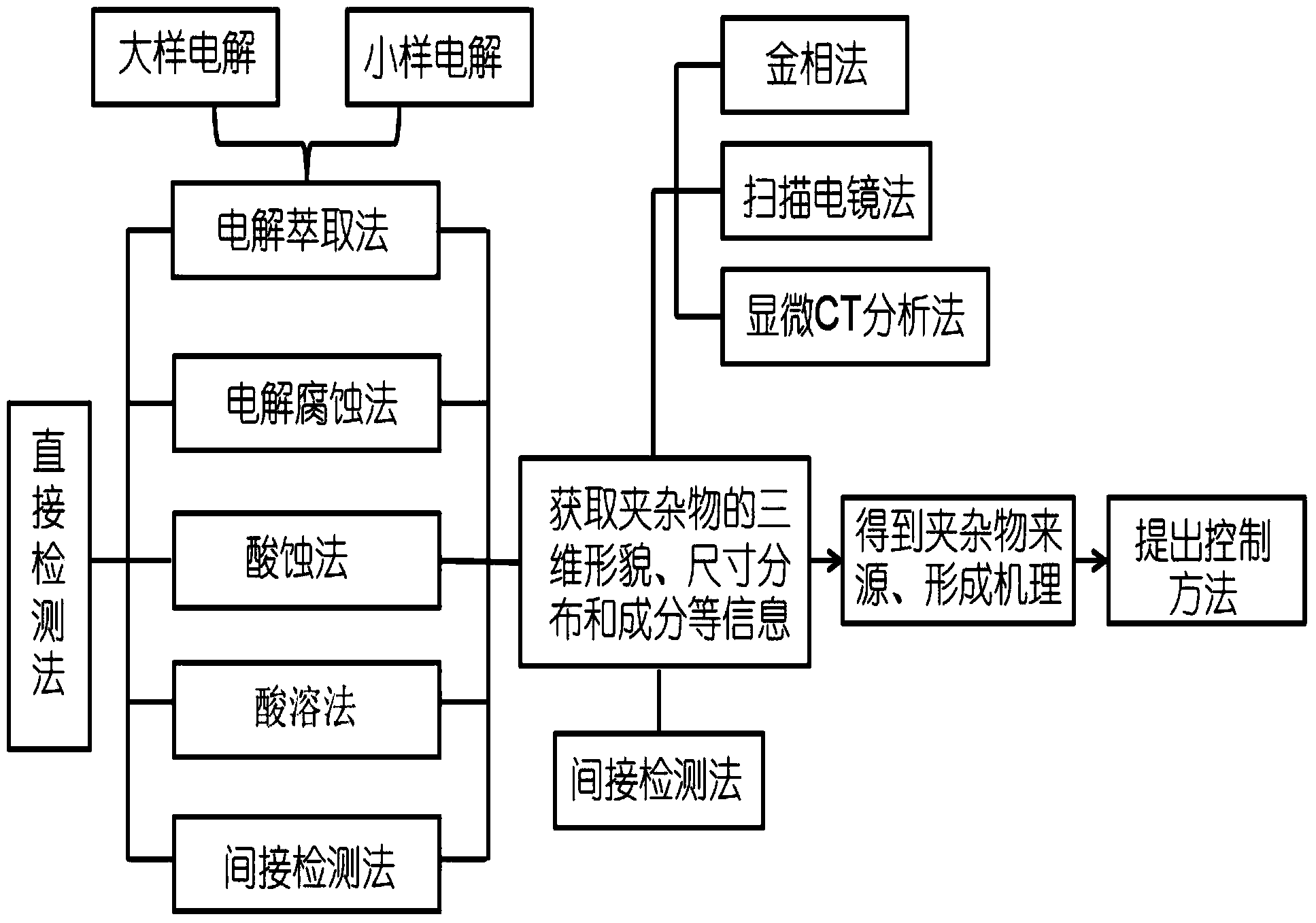

[0045] The present invention is a systematic analysis method for inclusions in steel from multi-stage sampling in the whole process of iron and steel smelting to processing the taken samples, including traditional two-dimensional detection method, non-destructive detection method, non-destructive extraction method of inclusions, inclusion Concentration methods, etc., and listed several sets of application results. The method of systematic analysis of inclusions in steel can comprehensively obtain the information of inclusions in steel, and trace the genetic information of inclusion defects in the final steel product, which has a good guiding effect on the production of clean steel.

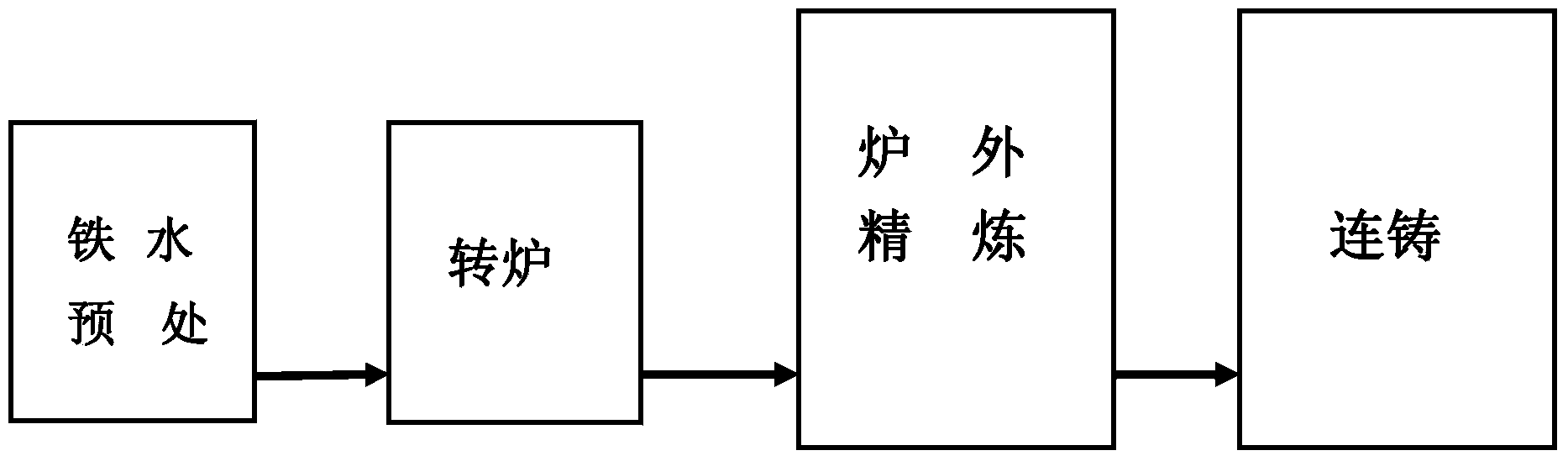

[0046] figure 1 It is a schematic diagram of multi-stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com