Unpowered hood

A hood and power technology, applied in the field of unpowered hoods, can solve the problems of short service life, inability to turn off heat preservation, large ventilation resistance coefficient, etc., and achieve the effects of easy application and popularization, reduction of heat loss, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

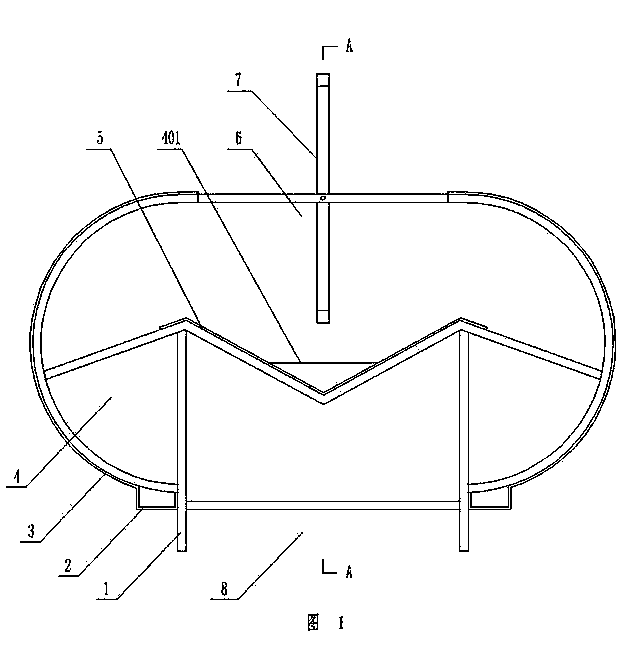

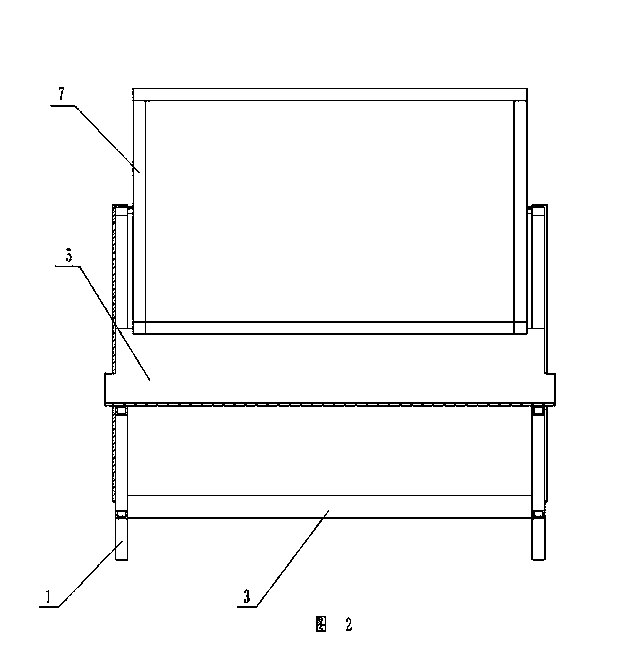

[0012] As shown in the figure, the unpowered hood has a structural support 1, and an arc-shaped outer guard plate 3 is symmetrically fixed on both sides of the structural support 1, and a water ditch 2 is arranged at the bottom of the outer guard plate 3 on both sides of the structural support 1 , The ditch 2 is integrated with the outer guard plate 3 for easy installation. The front and rear ends of the structural support 1 are respectively fixed with end plates 4, and the bottom and upper ends of the structural support 1 are located between the outer guard plates 3 on both sides to form an air inlet 8 and an air exhaust port 6 respectively. A V-shaped rain shield 5 with a width larger than the air inlet 8 and the air exhaust outlet 6 is fixed in the inner middle. Rain plate 5 is led out and is provided with water outlet 401, is hinged with the wind shield 7 that air outlet 6 can be closed at structural support 1 upper end, and the hinge shaft of wind shield 7 is positioned a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com