Expressway slope reinforcement structure

A technology for strengthening structures and highways, which is applied in basic structure engineering, excavation, construction, etc. It can solve the problems of difficult frame beam construction, high manpower investment, and large engineering volume, and achieve reasonable force, light structure, and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

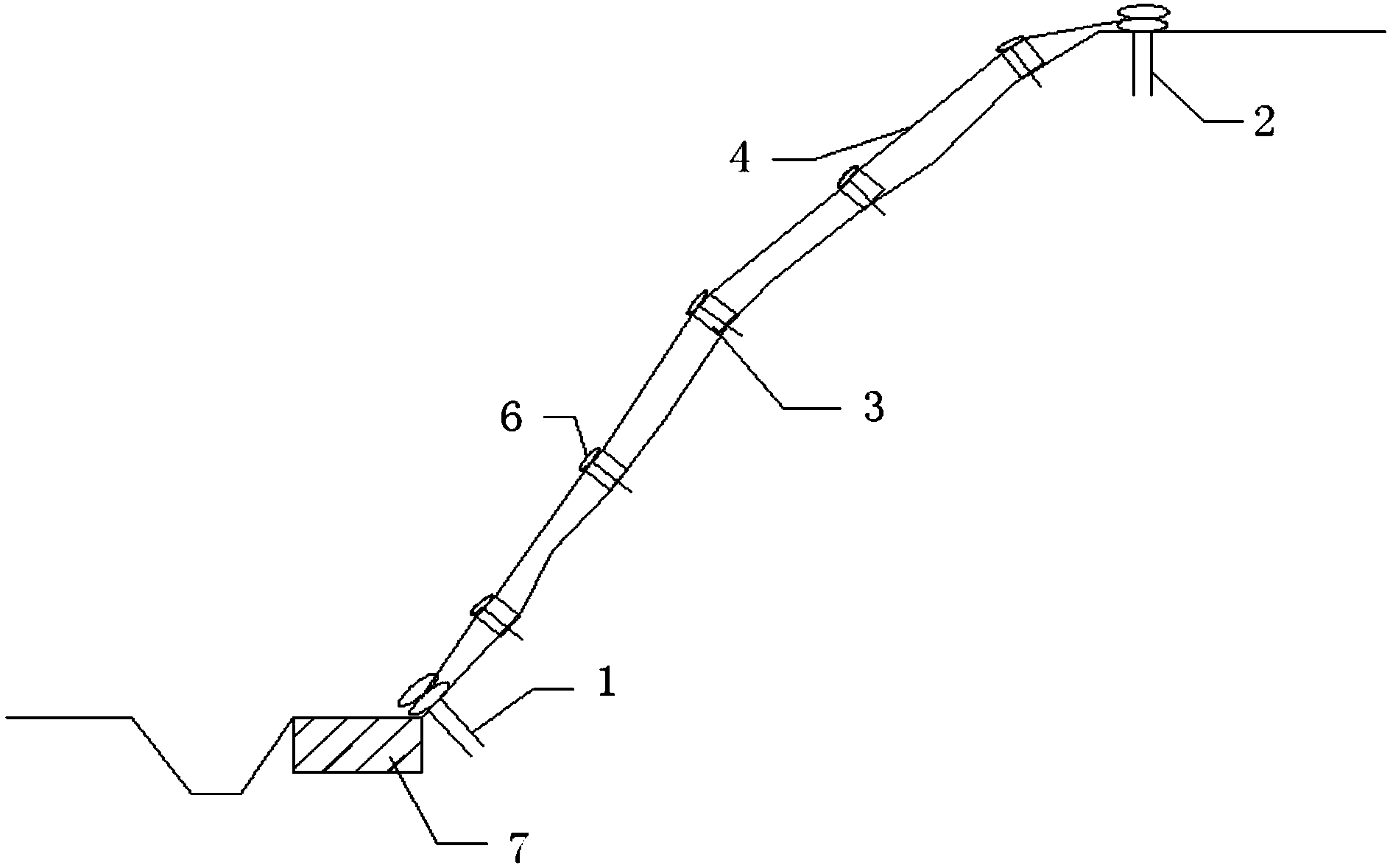

[0023] Below in conjunction with accompanying drawing, patent of the present invention is described further.

[0024] see figure 1 and figure 2 A plurality of concrete frame beams 3 with a transverse interval of 2m to 4m are arranged longitudinally along the slope, and a plurality of antirust prestressed steel strands 4 with longitudinal intervals of 1m to 3m and prestressed are laid along the slope. The line 4 is anchored and fixed on the upper layer of the concrete frame beam 3 with ordinary shallow anchor rods 6, and its two ends are respectively fixed on the first anchor rod 1 and the second anchor rod 2, and the first anchor rod 1 and the second anchor rod 2 They are respectively fixed in the rock and soil layer with relatively good mechanical properties at the foot of the slope and at the top of the slope by means of mechanical reaming, and drainage ditches 5 with an interval of 2m to 4m are arranged on the slope surface.

[0025] The prestress applied by the steel st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com